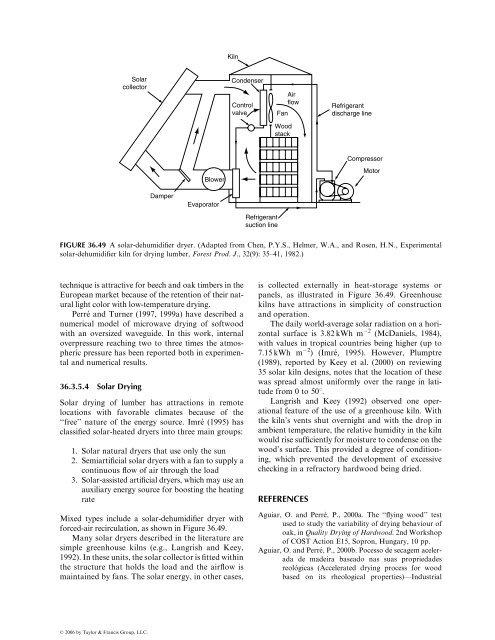

KilnSolarcollectorCondenserControlvalveAirflowFanRefrigerantdischarge line<strong>Wood</strong>stackCompressorBlowerMotorDamperEvaporatorRefrigerantsuction lineFIGURE <strong>36</strong>.49 A solar-dehumidifier dryer. (Adapted from Chen, P.Y.S., Helmer, W.A., and Rosen, H.N., Experimentalsolar-dehumidifier kiln for drying lumber, Forest Prod. J., 32(9): 35–41, 1982.)technique is attractive for beech and oak timbers in theEuropean market because <strong>of</strong> the retention <strong>of</strong> their naturallight color with low-temperature drying.Perré and Turner (1997, 1999a) have described anumerical model <strong>of</strong> microwave drying <strong>of</strong> s<strong>of</strong>twoodwith an oversized waveguide. In this work, internaloverpressure reaching two to three times the atmosphericpressure has been reported both in experimentaland numerical results.<strong>36</strong>.3.5.4 Solar <strong>Drying</strong>Solar drying <strong>of</strong> lumber has attractions in remotelocations with favorable climates because <strong>of</strong> the‘‘free’’ nature <strong>of</strong> the energy source. Imré (1995) hasclassified solar-heated dryers into three main groups:1. Solar natural dryers that use only the sun2. Semiartificial solar dryers with a fan to supply acontinuous flow <strong>of</strong> air through the load3. Solar-assisted artificial dryers, which may use anauxiliary energy source for boosting the heatingrateMixed types include a solar-dehumidifier dryer withforced-air recirculation, as shown in Figure <strong>36</strong>.49.Many solar dryers described in the literature aresimple greenhouse kilns (e.g., Langrish and Keey,1992). In these units, the solar collector is fitted withinthe structure that holds the load and the airflow ismaintained by fans. The solar energy, in other cases,is collected externally in heat-storage systems orpanels, as illustrated in Figure <strong>36</strong>.49. Greenhousekilns have attractions in simplicity <strong>of</strong> constructionand operation.The daily world-average solar radiation on a horizontalsurface is 3.82 kWh m 2 (McDaniels, 1984),with values in tropical countries being higher (up to7.15 kWh m 2 ) (Imré, 1995). However, Plumptre(1989), reported by Keey et al. (2000) on reviewing35 solar kiln designs, notes that the location <strong>of</strong> thesewas spread almost uniformly over the range in latitudefrom 0 to 508.Langrish and Keey (1992) observed one operationalfeature <strong>of</strong> the use <strong>of</strong> a greenhouse kiln. Withthe kiln’s vents shut overnight and with the drop inambient temperature, the relative humidity in the kilnwould rise sufficiently for moisture to condense on thewood’s surface. This provided a degree <strong>of</strong> conditioning,which prevented the development <strong>of</strong> excessivechecking in a refractory hardwood being dried.REFERENCESAguiar, O. and Perré, P., 2000a. The ‘‘flying wood’’ testused to study the variability <strong>of</strong> drying behaviour <strong>of</strong>oak, in Quality <strong>Drying</strong> <strong>of</strong> Hardwood. 2nd Workshop<strong>of</strong> COST Action E15, Sopron, Hungary, 10 pp.Aguiar, O. and Perré, P., 2000b. Pocesso de secagem aceleradade madeira baseado nas suas propriedadesreológicas (Accelerated drying process for woodbased on its rheological properties)—Industrialß 2006 by Taylor & Francis Group, LLC.

patten N 1265, Instituto nacional de proteçãoindustrial, Brazil.Aléon, D., Chanrion, P., Négrié, G., and Perré, P., 2003.FormaXylos 4—Le séchage (Training in <strong>Wood</strong> Science:<strong>Drying</strong>, Vol. 4), CD-Rom français/English,CTBA, Paris.Antti, A.L., 1992. Microwave drying <strong>of</strong> hardwood: simultaneousmeasurements <strong>of</strong> pressure temperature andweight reduction, Forest Prod. J., 42(6): 49–54.Ashworth, J.C., 1977. The mathematical simulation <strong>of</strong>batch-drying <strong>of</strong> s<strong>of</strong>twood timber, Ph.D. thesis, University<strong>of</strong> Canterbury, New Zealand.Ashworth, J.C. and Keey, R.B., 1979. The kiln seasoning <strong>of</strong>s<strong>of</strong>twood boards, Chem. Eng., 347(8): 593–598, 607.Audebert, P. and Temmar, A., 1997. Vacuum drying <strong>of</strong>oakwood: moisture strains and drying process, <strong>Drying</strong>Technol., 15: 2281–2302.Banks, W.B., 1968. A technique for measuring the lateralpermeability <strong>of</strong> wood, J. Inst. <strong>Wood</strong> Sci., 4(2): 35–41.Behnke, C. and Militzer, K.-E., 1996. Vacuum dryer model,Proceedings <strong>of</strong> the Fifth International <strong>Wood</strong> <strong>Drying</strong>Conference, Québec, Canada, pp. 139–145.Bolton, A.J. and Petty, J.A., 1978. The relationship betweenthe axial permeability <strong>of</strong> wood to dry air and to a nonpolar solvent, <strong>Wood</strong> Sci. Technol., 12: 111–126.Booker, R.E., 1994. Collapse or internal checking, whichcomes first? Proceedings <strong>of</strong> the 4th IUFRO <strong>Wood</strong><strong>Drying</strong> Conference, 133–140, Rotorua, New Zealand.Booker, R.E., 1996. New theories for liquid water flow inwood, Proceedings <strong>of</strong> the 5th IUFRO <strong>Wood</strong> <strong>Drying</strong>Conference, 437–445, Québec, Canada.Boone, R.S., Kozlik, C.J., Bois, P.J., and Wegert, E.M.,1988. Dry kiln schedules for commercialwoods temperate and tropical, USDA FS ForestProducts Laboratory, General Technical ReportFRL-GTR-57.Bosshard, H.H., 1984. Holzkunde, Band 2, Zur Biologie,Physik und Chemie des Holzes (<strong>Wood</strong> Science: Biology,Physics and Chemistry <strong>of</strong> <strong>Wood</strong>, Vol. 2), BirkhäuserVerlag, Basel.Brandaõ, A. and Perré, P., 1996. The ‘‘flying wood’’: aquick test to characterise the drying behaviour <strong>of</strong>tropical woods, Proceedings <strong>of</strong> the Fifth InternationalIUFRO <strong>Wood</strong> <strong>Drying</strong> Conference, Québec, Canada,pp. 315–324.Carlquist, S., 2001. Comparative <strong>Wood</strong> Anatomy, Springer,Berlin.Chen, G., Keey, R.B., and Walker, J.C.F., 1997a. Thedrying stress and check development on hightemperaturekiln seasoning <strong>of</strong> sapwood Pinusradiata boards, Holz Roh-Werks., 55: 59–64.Chen, G., Keey, R.B., and Walker, J.C.F., 1997b. Stressrelief for sapwood Pinus radiata boards by coolingand steam-conditioning processes, Holz als Roh-Werks., 55: 351–<strong>36</strong>0.Chen, P.Y.S., Helmer, W.A., and Rosen, H.N., 1982. Experimentalsolar-dehumidifier kiln for drying lumber,Forest Prod. J., 32(9): 35–41.Chen, P.Y.S., Zhang G., van Sambeek J.W., 1998. Relationshipsamong growth rate, vessel lumen area,and wood permeability for three central hardwoodspecies, Forest Products Journal, 48:87–90.Choong, E.T. and Kimbler, O.K., 1971. A technique <strong>of</strong>measuring water flow in woods <strong>of</strong> low permeability,<strong>Wood</strong> Sci., 4(1): 32–<strong>36</strong>.Choong, E.T. and Tesoro, F.O., 1989. Relationship <strong>of</strong> capillarypressure and water saturation in wood,<strong>Wood</strong> Sci. Technol., 23: 139–150.Choong, E.T., Tesoro, F.O., and Manwiller, F.G., 1974.Permeability <strong>of</strong> twenty-two small diameter hardwoodsgrowing on southern pine sites, <strong>Wood</strong>Fiber, 6(1): 91–101.Cloutier, A. and Fortin, Y., 1991. Moisture content–water potential relationship <strong>of</strong> wood from saturatedto dry conditions, <strong>Wood</strong> Sci. Technol., 25:263–280.Clair, B., 2001. Etude des propriétésmécaniques et du retraitau séchage du bois à l’échelle de la paroi cellulaire:essai de compréhension du comportement macroscopiqueparadoxal du bois de tension à couche gélatineuse,PhD dissertation, ENGREF, Montpellier.Comstock, G.L., 1967. Longitudinal permeability <strong>of</strong> woodto gases and nonswelling liquids, Forest Prod. J.,17(10): 41–46.Comstock, G.L., 1970. Directional permeability <strong>of</strong> s<strong>of</strong>twoods,<strong>Wood</strong> Fiber, 1: 283–289.Comstock, G.L. and Côté, W.E., 1968. Factors affectingpermeability and pit aspiration in coniferous sapwood,<strong>Wood</strong> Sci. Technol., 2: 279–291.Cown, D.J., 1992. New Zealand radiata pine and Douglasfirsuitability for processing, FRI Bull., 168,NZFRI, Rotorua.Cown, D.J. and McConchie, D.L., 1983. Studies on theintrinsic properties <strong>of</strong> new-crop radiata pine II:wood characteristics <strong>of</strong> 10 trees from a 24-year-oldstand grown in the Central North Island, FRI Bull.,37, NZFRI, Rotorua.Culpepper, L., 1990. High temperature drying-enhancingkiln operations, Miller Freeman, San Francisco, CA.Dahlblom O., Petersson H. and Ormarsson S., 1994.Numerical simulation <strong>of</strong> the development <strong>of</strong> deformationand stress in wood during drying, proceedings<strong>of</strong> the 4th IUFRO <strong>Wood</strong> <strong>Drying</strong>Symposium, 165–180, Rotorua, New Zealand.Dahlblom O., Ormarsson S. and Petersson H., 1996. Simulation<strong>of</strong> wood deformation processes in drying andother environmental loading, Annals <strong>of</strong> Forest Science,53: 857–866.Davis, C.P., 2001. <strong>Drying</strong> Pinus radiata boards in dehumidifierconditions, Ph.D. thesis, Otago University,New Zealand.Davis, C.P., Carrington, C.G., and Sun, Z.F., 2001. <strong>Drying</strong>rate curves for the dehumidifier drying <strong>of</strong> Pinusradiata boards, Proceedings <strong>of</strong> the Seventh InternationalIUFRO <strong>Wood</strong> <strong>Drying</strong> Conference, Tsukuba,Japan, pp. 216–221.Davis, C.P., Carrington, C.G., and Sun, Z.F., 2002. Theinfluence <strong>of</strong> compression wood on the drying curves<strong>of</strong> Pinus radiata in dehumidifier conditions, <strong>Drying</strong>Technol., 20: 2005–2026.ß 2006 by Taylor & Francis Group, LLC.