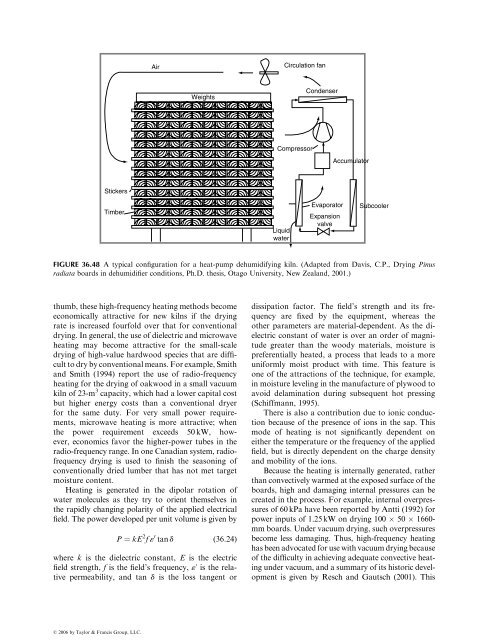

oards by conduction whereas the vacuum levelis used to enhance the internal mass transfer.. Discontinuously operating kilns, with twoperiods <strong>of</strong> about 1 h alternate: a heating periodat atmospheric pressure and a drying period atreduced pressure.. Finally, the most recent ‘‘high-vac’’ kilns use aslightly higher pressure level (more than 100mbar), together a very high linear air velocity(10 m s 1 or more), to compensate for the loss <strong>of</strong>thermal capacity <strong>of</strong> the air; this method hasproved to be very effective.In the latter method, uniformity <strong>of</strong> the air distributionthrough the load is important to ensure evenness <strong>of</strong>drying, with regions <strong>of</strong> low velocities resulting inhigher final moisture contents (Ledig and Militzer,1999). The positions <strong>of</strong> fans and heating coils havean important bearing on the temperature and on thefinal moisture content <strong>of</strong> the load (Hedlund, 1996).Vacuum dryers with overhead fans provide a fairlycontrolled airflow path through the load, but otherfan locations can result in ill-defined pressure andsuction sides. An overhead-fan dryer, however, wasfound to yield a systematic variation in temperaturebetween the door and the other end <strong>of</strong> the dryer,which might have been reduced by dividing the unitinto separate temperature-control zones. Techniquesto overcome the inherent poor heat transfer invacuum dryers include the use <strong>of</strong> heated plates betweenthe boards or intermittent heating with superheatedsteam. Another suggested technique employs aheating cycle at atmospheric pressure, when the heattransfer is better, followed by a vacuum-drying cycle(Guilmain et al., 1996). Tests on drying oakwood atpilot and industrial scales showed that the discontinuousprocess was faster, with less susceptibility tomechanical damage <strong>of</strong> the wood, but the thermalconsumption was higher than under continuousvacuum conditions.Behnke and Militzer (1996) have produced avacuum-dryer model for design and process-controlpurposes based on a characteristic drying curve for thewood’sdryingbehavior.Hilderbrand(1989)claimsthatcommercialdryingtimeinvacuumkilnsvariesbetweenone half and one third <strong>of</strong> those found in conventionalconvective kilns under atmospheric pressure.<strong>36</strong>.3.5 .2 Dehum idifi er Kiln s<strong>Drying</strong> at low temperatures, which is a feature <strong>of</strong>seasoning refractory timbers, is energy-inefficient.A dehumidifier kiln reduces the thermal-energy consumptionby incorporating an air-conditioning unitthat recovers heat by cooling the kiln air below itsdew point and, in effect, recycling the latent heat <strong>of</strong>condensation. As moisture is removed as condensedliquid rather than vapor in warm discharged air, theassociated thermal loss is avoided. However, a smallamount <strong>of</strong> venting is needed for humidity-controlpurposes. Volatile organic chemicals normally removedwith the vented moist air now appear in thecondensate stream, which potentially could be sent toa separate unit for chemical recovery.Figure <strong>36</strong>.48 shows the layout <strong>of</strong> a heat-pumpdehumidifying kiln. Moist air is drawn over the evaporatorand condenser consecutively in a Rankine cycleheat pump. Besides these basic elements such as anevaporator, a condenser with its associated compressor,and expansion valve, there is an accumulator thatprevents the refrigerant from entering and damagingthe compressor and a subcooling heat exchanger toenhance the effectiveness <strong>of</strong> the heat pump.The performance <strong>of</strong> dehumidifier kilns is normallyexpressed in terms <strong>of</strong> the specific moisture-extractionrate (SMER), which is the amount <strong>of</strong> moistureextracted per unit energy input. Two such ratiosmay be defined: one representing how effectively thedehumidifier extracts moisture from the air as condensateand the other (the kiln SMER) representinghow efficiently the kiln removes moisture from thelumber including the condensate and venting. Thekiln SMER for convective kilns is limited to about0.8 to 0.9 kg kWh 1 , compared with values in therange <strong>of</strong> 1.5 to 2.5 kg kWh 1 for commercial dehumidifierkilns (Davis, 2001). Some <strong>of</strong> the lower valuesmay reflect the poor insulation <strong>of</strong> the tested kilnsrather than a defect in the process.Dehumidifying kilns are limited in operating temperatureby the working limits <strong>of</strong> the compressor(

AirCirculation fanWeightsCondenserCompressorAccumulatorStickersTimberLiquidwaterEvaporatorExpansionvalveSubcoolerFIGURE <strong>36</strong>.48 A typical configuration for a heat-pump dehumidifying kiln. (Adapted from Davis, C.P., <strong>Drying</strong> Pinusradiata boards in dehumidifier conditions, Ph.D. thesis, Otago University, New Zealand, 2001.)thumb, these high-frequency heating methods becomeeconomically attractive for new kilns if the dryingrate is increased fourfold over that for conventionaldrying. In general, the use <strong>of</strong> dielectric and microwaveheating may become attractive for the small-scaledrying <strong>of</strong> high-value hardwood species that are difficultto dry by conventional means. For example, Smithand Smith (1994) report the use <strong>of</strong> radio-frequencyheating for the drying <strong>of</strong> oakwood in a small vacuumkiln <strong>of</strong> 23-m 3 capacity, which had a lower capital costbut higher energy costs than a conventional dryerfor the same duty. For very small power requirements,microwave heating is more attractive; whenthe power requirement exceeds 50 kW, however,economics favor the higher-power tubes in theradio-frequency range. In one Canadian system, radi<strong>of</strong>requencydrying is used to finish the seasoning <strong>of</strong>conventionally dried lumber that has not met targetmoisture content.Heating is generated in the dipolar rotation <strong>of</strong>water molecules as they try to orient themselves inthe rapidly changing polarity <strong>of</strong> the applied electricalfield. The power developed per unit volume is given byP ¼ kE 2 f « 0 tan d (<strong>36</strong>:24)where k is the dielectric constant, E is the electricfield strength, f is the field’s frequency, «’ is the relativepermeability, and tan d is the loss tangent ordissipation factor. The field’s strength and its frequencyare fixed by the equipment, whereas theother parameters are material-dependent. As the dielectricconstant <strong>of</strong> water is over an order <strong>of</strong> magnitudegreater than the woody materials, moisture ispreferentially heated, a process that leads to a moreuniformly moist product with time. This feature isone <strong>of</strong> the attractions <strong>of</strong> the technique, for example,in moisture leveling in the manufacture <strong>of</strong> plywood toavoid delamination during subsequent hot pressing(Schiffmann, 1995).There is also a contribution due to ionic conductionbecause <strong>of</strong> the presence <strong>of</strong> ions in the sap. Thismode <strong>of</strong> heating is not significantly dependent oneither the temperature or the frequency <strong>of</strong> the appliedfield, but is directly dependent on the charge densityand mobility <strong>of</strong> the ions.Because the heating is internally generated, ratherthan convectively warmed at the exposed surface <strong>of</strong> theboards, high and damaging internal pressures can becreated in the process. For example, internal overpressures<strong>of</strong> 60 kPa have been reported by Antti (1992) forpower inputs <strong>of</strong> 1.25 kW on drying 100 50 1660-mm boards. Under vacuum drying, such overpressuresbecome less damaging. Thus, high-frequency heatinghas been advocated for use with vacuum drying because<strong>of</strong> the difficulty in achieving adequate convective heatingunder vacuum, and a summary <strong>of</strong> its historic developmentis given by Resch and Gautsch (2001). Thisß 2006 by Taylor & Francis Group, LLC.