36 Drying of Wood

36 Drying of Wood

36 Drying of Wood

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

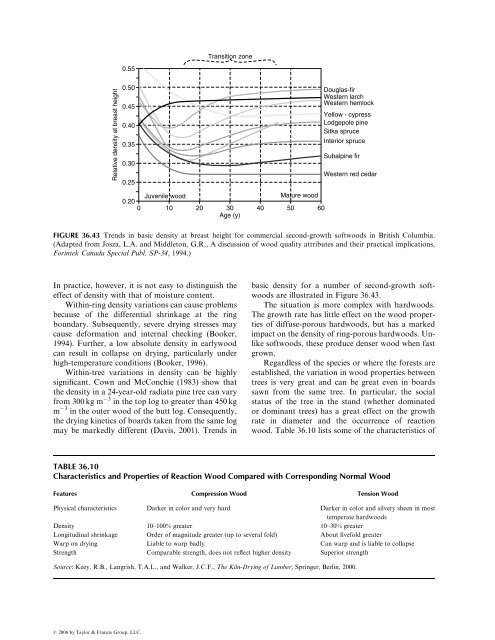

Transition zone0.55Relative density at breast height0.500.450.400.350.300.25Douglas-firWestern larchWestern hemlockYellow - cypressLodgepole pineSitka spruceInterior spruceSubalpine firWestern red cedar0.200Juvenile wood10 20 30Age (y)Mature wood40 50 60FIGURE <strong>36</strong>.43 Trends in basic density at breast height for commercial second-growth s<strong>of</strong>twoods in British Columbia.(Adapted from Josza, L.A. and Middleton, G.R., A discussion <strong>of</strong> wood quality attributes and their practical implications,Forintek Canada Special Publ. SP-34, 1994.)In practice, however, it is not easy to distinguish theeffect <strong>of</strong> density with that <strong>of</strong> moisture content.Within-ring density variations can cause problemsbecause <strong>of</strong> the differential shrinkage at the ringboundary. Subsequently, severe drying stresses maycause deformation and internal checking (Booker,1994). Further, a low absolute density in earlywoodcan result in collapse on drying, particularly underhigh-temperature conditions (Booker, 1996).Within-tree variations in density can be highlysignificant. Cown and McConchie (1983) show thatthe density in a 24-year-old radiata pine tree can varyfrom 300 kg m 3 in the top log to greater than 450 kgm 3 in the outer wood <strong>of</strong> the butt log. Consequently,the drying kinetics <strong>of</strong> boards taken from the same logmay be markedly different (Davis, 2001). Trends inbasic density for a number <strong>of</strong> second-growth s<strong>of</strong>twoodsare illustrated in Figure <strong>36</strong>.43.The situation is more complex with hardwoods.The growth rate has little effect on the wood properties<strong>of</strong> diffuse-porous hardwoods, but has a markedimpact on the density <strong>of</strong> ring-porous hardwoods. Unlikes<strong>of</strong>twoods, these produce denser wood when fastgrown.Regardless <strong>of</strong> the species or where the forests areestablished, the variation in wood properties betweentrees is very great and can be great even in boardssawn from the same tree. In particular, the socialstatus <strong>of</strong> the tree in the stand (whether dominatedor dominant trees) has a great effect on the growthrate in diameter and the occurrence <strong>of</strong> reactionwood. Table <strong>36</strong>.10 lists some <strong>of</strong> the characteristics <strong>of</strong>TABLE <strong>36</strong>.10Characteristics and Properties <strong>of</strong> Reaction <strong>Wood</strong> Compared with Corresponding Normal <strong>Wood</strong>Features Compression <strong>Wood</strong> Tension <strong>Wood</strong>Physical characteristics Darker in color and very hard Darker in color and silvery sheen in mosttemperate hardwoodsDensity 10–100% greater 10–30% greaterLongitudinal shrinkage Order <strong>of</strong> magnitude greater (up to several fold) About fivefold greaterWarp on drying Liable to warp badly Can warp and is liable to collapseStrength Comparable strength, does not reflect higher density Superior strengthSource: Keey, R.B., Langrish, T.A.L., and Walker, J.C.F., The Kiln-<strong>Drying</strong> <strong>of</strong> Lumber, Springer, Berlin, 2000.ß 2006 by Taylor & Francis Group, LLC.