Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

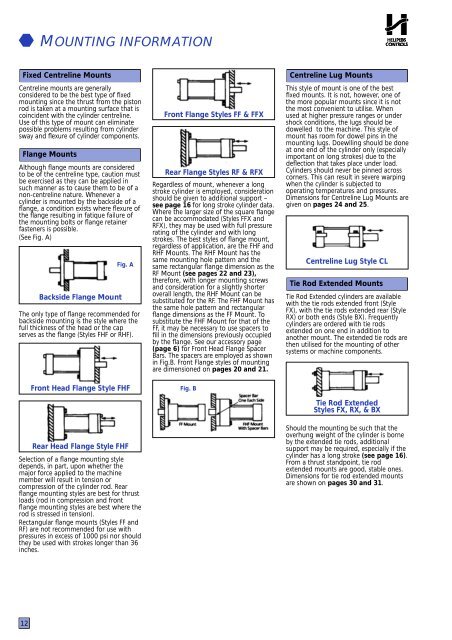

MOUNTING INFORMATIONFixed Centreline MountsCentreline mounts are generallyconsidered to be the best type of fixedmounting since the thrust from the pistonrod is taken at a mounting surface that iscoincident with the <strong>cylinder</strong> centreline.Use of this type of mount can eliminatepossible problems resulting from <strong>cylinder</strong>sway and flexure of <strong>cylinder</strong> components.Flange MountsAlthough flange mounts are consideredto be of the centreline type, caution mustbe exercised as they can be applied insuch manner as to cause them to be of anon-centreline nature. Whenever a<strong>cylinder</strong> is mounted by the backside of aflange, a condition exists where flexure ofthe flange resulting in fatique failure ofthe mounting bolts or flange retainerfasteners is possible.(See Fig. A)Backside Flange MountFig. AThe only type of flange recommended forbackside mounting is the style where thefull thickness of the head or the capserves as the flange (Styles FHF or RHF).Front Head Flange Style FHFRear Head Flange Style FHFSelection of a flange mounting styledepends, in part, upon whether themajor force applied to the machinemember will result in tension orcompression of the <strong>cylinder</strong> rod. Rearflange mounting styles are best for thrustloads (rod in compression and frontflange mounting styles are best where therod is stressed in tension).Rectangular flange mounts (Styles FF andRF) are not recommended for use withpressures in excess of 1000 psi nor shouldthey be used with strokes longer than 36inches.Front Flange Styles FF & FFXRear Flange Styles RF & R F XRegardless of mount, whenever a longstroke <strong>cylinder</strong> is employed, considerationshould be given to additional support –see page 16 for long stroke <strong>cylinder</strong> data.Where the larger size of the square flangecan be accommodated (Styles FFX andRFX), they may be used with full pressurerating of the <strong>cylinder</strong> and with longstrokes. The best styles of flange mount,regardless of application, are the FHF andRHF Mounts. The RHF Mount has thesame mounting hole pattern and thesame rectangular flange dimension as theRF Mount (see pages 22 and 23),therefore, with longer mounting screwsand consideration for a slightly shorteroverall length, the RHF Mount can besubstituted for the RF. The FHF Mount hasthe same hole pattern and rectangularflange dimensions as the FF Mount. Tosubstitute the FHF Mount for that of theFF, it may be necessary to use spacers tofill in the dimensions previously occupiedby the flange. See our accessory page(page 6) for Front Head Flange SpacerBars. The spacers are employed as shownin Fig.B. Front Flange styles of mountingare dimensioned on pages 20 and 21.Fig. BCentreline Lug MountsThis style of mount is one of the bestfixed mounts. It is not, however, one ofthe more popular mounts since it is notthe most convenient to utilise. Whenused at higher pressure ranges or undershock conditions, the lugs should bedowelled to the machine. This style ofmount has room for dowel pins in themounting lugs. Doewlling should be doneat one end of the <strong>cylinder</strong> only (especiallyimportant on long strokes) due to thedeflection that takes place under load.Cylinders should never be pinned acrosscorners. This can result in severe warpingwhen the <strong>cylinder</strong> is subjected tooperating temperatures and pressures.Dimensions for Centreline Lug Mounts aregiven on pages 24 and 25.Centreline Lug Style CL<strong>Tie</strong> <strong>Rod</strong> Extended Mounts<strong>Tie</strong> <strong>Rod</strong> Extended <strong>cylinder</strong>s are availablewith the tie rods extended front (StyleFX), with the tie rods extended rear (StyleRX) or both ends (Style BX). Frequently<strong>cylinder</strong>s are ordered with tie rodsextended on one end in addition toanother mount. The extended tie rods arethen utilised for the mounting of othersystems or machine components.<strong>Tie</strong> <strong>Rod</strong> ExtendedStyles FX, RX, & BXShould the mounting be such that theoverhung weight of the <strong>cylinder</strong> is borneby the extended tie rods, additionalsupport may be required, especially if the<strong>cylinder</strong> has a long stroke (see page 16).From a thrust standpoint, tie rodextended mounts are good, stable ones.Dimensions for tie rod extended mountsare shown on pages 30 and 31.12