Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

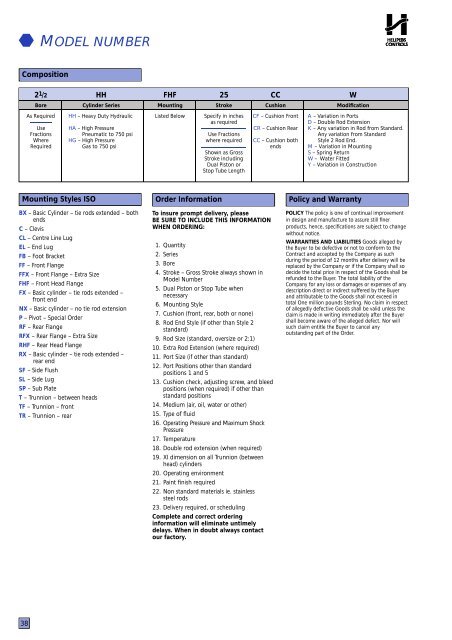

MODEL NUMBERComposition2 1 /2 HH FHF 25 CC WBore Cylinder Series Mounting Stroke Cushion ModificationAs Required HH – Heavy Duty <strong>Hydraulic</strong> Listed Below Specify in inches CF – Cushion Front A – Variation in Portsas requiredD – Double <strong>Rod</strong> ExtensionUse HA – High Pressure CR – Cushion Rear K – Any variation in <strong>Rod</strong> from Standard.Fractions Pneumatic to 750 psi Use Fractions Any variation from StandardWhere HG – High Pressure where required CC – Cushion both Style 2 <strong>Rod</strong> End.Required Gas to 750 psi ends M – Variation in MountingShown as GrossS – Spring ReturnStroke includingW – Water FittedDual Piston orY – Variation in ConstructionStop Tube LengthMounting Styles ISO Order Information Policy and WarrantyBX – Basic Cylinder – tie rods extended – bothendsC – ClevisCL – Centre Line LugEL – End LugFB – Foot BracketFF – Front FlangeFFX – Front Flange – Extra SizeFHF – Front Head FlangeFX – Basic <strong>cylinder</strong> – tie rods extended –front endNX – Basic <strong>cylinder</strong> – no tie rod extensionP – Pivot – Special OrderRF – Rear FlangeRFX – Rear Flange – Extra SizeRHF – Rear Head FlangeRX – Basic <strong>cylinder</strong> – tie rods extended –rear endSF – Side FlushSL – Side LugSP – Sub PlateT – Trunnion – between headsTF – Trunnion – frontTR – Trunnion – rearTo insure prompt delivery, pleaseBE SURE TO INCLUDE THIS INFORMATIONWHEN ORDERING:1. Quantity2. Series3. Bore4. Stroke – Gross Stroke always shown inModel Number5. Dual Piston or Stop Tube whennecessary6. Mounting Style7. Cushion (front, rear, both or none)8. <strong>Rod</strong> End Style (if other than Style 2standard)9. <strong>Rod</strong> Size (standard, oversize or 2:1)10. Extra <strong>Rod</strong> Extension (where required)11. Port Size (if other than standard)12. Port Positions other than standardpositions 1 and 513. Cushion check, adjusting screw, and bleedpositions (when required) if other thanstandard positions14. Medium (air, oil, water or other)15. Type of fluid16. Operating Pressure and Maximum ShockP r e s s u r e17. Temperature18. Double rod extension (when required)19. XI dimension on all Trunnion (betweenhead) <strong>cylinder</strong>s20. Operating environment21. Paint finish required22. Non standard materials ie. stainlesssteel rods23. Delivery required, or schedulingComplete and correct orderinginformation will eliminate untimelydelays. When in doubt always contactour factory.POLICY The policy is one of continual improvementin design and manufacture to assure still finerproducts, hence, specifications are subject to changewithout notice.WARRANTIES AND LIABILITIES Goods alleged bythe Buyer to be defective or not to conform to theContract and accepted by the Company as suchduring the period of 12 months after delivery will bereplaced by the Company or if the Company shall sodecide the total price in respect of the Goods shall berefunded to the Buyer. The total liability of theCompany for any loss or damages or expenses of anydescription direct or indirect suffered by the Buyerand attributable to the Goods shall not exceed intotal One million pounds Sterling. No claim in respectof allegedly defective Goods shall be valid unless theclaim is made in writing immediately after the Buyershall become aware of the alleged defect. Nor willsuch claim entitle the Buyer to cancel anyoutstanding part of the Order.38