Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Hydraulic cylinder Tie Rod Design - imperial - Duncan Rogers

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

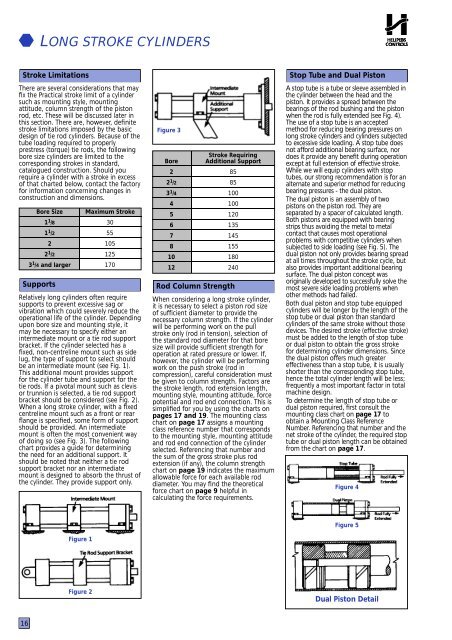

LONG STROKE CYLINDERSStroke LimitationsThere are several considerations that mayfix the Practical stroke limit of a <strong>cylinder</strong>such as mounting style, mountingattitude, column strength of the pistonrod, etc. These will be discussed later inthis section. There are, however, definitestroke limitations imposed by the basicdesign of tie rod <strong>cylinder</strong>s. Because of thetube loading required to properlyprestress (torque) tie rods, the followingbore size <strong>cylinder</strong>s are limited to thecorresponding strokes in standard,catalogued construction. Should yourequire a <strong>cylinder</strong> with a stroke in excessof that charted below, contact the factoryfor information concerning changes inconstruction and dimensions.Bore SizeSupportsMaximum Stroke1 1 /8 301 1 /2 552 1052 1 /2 1253 1 /4 and larger 170Relatively long <strong>cylinder</strong>s often requiresupports to prevent excessive sag orvibration which could severely reduce theoperational life of the <strong>cylinder</strong>. Dependingupon bore size and mounting style, itmay be necessary to specify either anintermediate mount or a tie rod supportbracket. If the <strong>cylinder</strong> selected has afixed, non-centreline mount such as sidelug, the type of support to select shouldbe an intermediate mount (see Fig. 1).This additional mount provides supportfor the <strong>cylinder</strong> tube and support for thetie rods. If a pivotal mount such as clevisor trunnion is selected, a tie rod supportbracket should be considered (see Fig. 2).When a long stroke <strong>cylinder</strong>, with a fixedcentreline mount such as a front or rearflange is specified, some form of supportshould be provided. An intermediatemount is often the most convenient wayof doing so (see Fig. 3). The followingchart provides a guide for determiningthe need for an additional support. Itshould be noted that neither a tie rodsupport bracket nor an intermediatemount is designed to absorb the thrust ofthe <strong>cylinder</strong>. They provide support only.Figure 3BoreStroke RequiringAdditional Support2 852 1 /2 853 1 /4 1004 1005 1206 1357 1458 15510 18012 240<strong>Rod</strong> Column StrengthWhen considering a long stroke <strong>cylinder</strong>,it is necessary to select a piston rod sizeof sufficient diameter to provide thenecessary column strength. If the <strong>cylinder</strong>will be performing work on the pullstroke only (rod in tension), selection ofthe standard rod diameter for that boresize will provide sufficient strength foroperation at rated pressure or lower. If,however, the <strong>cylinder</strong> will be performingwork on the push stroke (rod incompression), careful consideration mustbe given to column strength. Factors arethe stroke length, rod extension length,mounting style, mounting attitude, forcepotential and rod end connection. This issimplified for you by using the charts onpages 17 and 19. The mounting classchart on page 17 assigns a mountingclass reference number that correspondsto the mounting style, mounting attitudeand rod end connection of the <strong>cylinder</strong>selected. Referencing that number andthe sum of the gross stroke plus rodextension (if any), the column strengthchart on page 19 indicates the maximumallowable force for each available roddiameter. You may find the theoreticalforce chart on page 9 helpful incalculating the force requirements.Stop Tube and Dual PistonA stop tube is a tube or sleeve assembled inthe <strong>cylinder</strong> between the head and thepiston. It provides a spread between thebearings of the rod bushing and the pistonwhen the rod is fully extended (see Fig. 4).The use of a stop tube is an acceptedmethod for reducing bearing pressures onlong stroke <strong>cylinder</strong>s and <strong>cylinder</strong>s subjectedto excessive side loading. A stop tube doesnot afford additional bearing surface, nordoes it provide any benefit during operationexcept at full extension of effective stroke.While we will equip <strong>cylinder</strong>s with stoptubes, our strong recommendation is for analternate and superior method for reducingbearing pressures - the dual piston.The dual piston is an assembly of twopistons on the piston rod. They areseparated by a spacer of calculated length.Both pistons are equipped with bearingstrips thus avoiding the metal to metalcontact that causes most operationalproblems with competitive <strong>cylinder</strong>s whensubjected to side loading (see Fig. 5). Thedual piston not only provides bearing spreadat all times throughout the stroke cycle, butalso provides important additional bearingsurface. The dual piston concept wasoriginally developed to successfully solve themost severe side loading problems whenother methods had failed.Both dual piston and stop tube equipped<strong>cylinder</strong>s will be longer by the length of thestop tube or dual piston than standard<strong>cylinder</strong>s of the same stroke without thosedevices. The desired stroke (effective stroke)must be added to the length of stop tubeor dual piston to obtain the gross strokefor determining <strong>cylinder</strong> dimensions. Sincethe dual piston offers much greatereffectiveness than a stop tube, it is usuallyshorter than the corresponding stop tube,hence the total <strong>cylinder</strong> length will be less;frequently a most important factor in totalmachine design.To determine the length of stop tube ordual piston required, first consult themounting class chart on page 17 t oobtain a Mounting Class ReferenceN u m b e r. Referencing that number and thenet stroke of the <strong>cylinder</strong>, the required stoptube or dual piston length can be obtainedfrom the chart on page 17.Figure 4Figure 1Figure 5Figure 2Dual Piston Detail16