Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

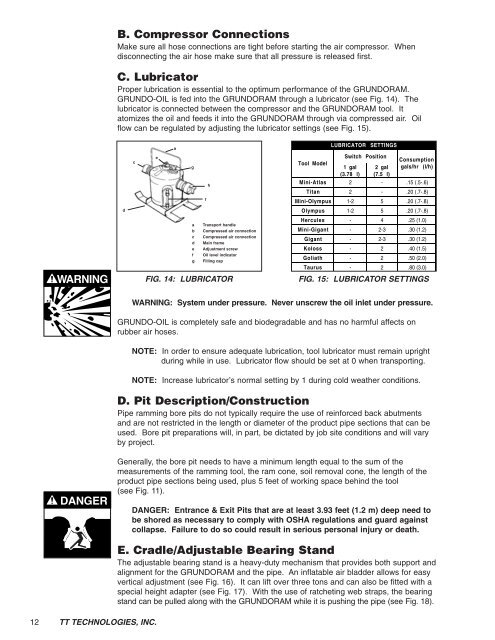

B. Compressor ConnectionsMake sure all hose connections are tight before starting the air compressor. Whendisconnecting the air hose make sure that all pressure is released first.C. LubricatorProper lubrication is essential to the optimum performance of the GRUNDORAM.GRUNDO-OIL is fed into the GRUNDORAM through a lubricator (see Fig. 14). Thelubricator is connected between the compressor and the GRUNDORAM tool. Itatomizes the oil and feeds it into the GRUNDORAM through via compressed air. Oilflow can be regulated by adjusting the lubricator settings (see Fig. 15).aLUBRICATOR SE<strong>TT</strong>INGScegTool ModelSwitch Position1 gal(3.78 l)2 gal(7.5 l)Consumptiongals/hr (l/h)hMini-Atlas 2 - .15 (.5-.6)Titan 2 - .20 (.7-.8)fMini-Olympus 1-2 5 .20 (.7-.8)dOlympus 1-2 5 .20 (.7-.8)abTransport handleCompressed air connectionHercules - 4 .25 (1.0)Mini-Gigant - 2-3 .30 (1.2)cdefgCompressed air connectionMain frameAdjustment screwOil level indicatorFilling capGigant - 2-3 .30 (1.2)Koloss - 2 .40 (1.5)Goliath - 2 .50 (2.0)Taurus - 2 .80 (3.0)FIG. 14: LUBRICATORFIG. 15: LUBRICATOR SE<strong>TT</strong>INGSWARNING: System under pressure. Never unscrew the oil inlet under pressure.GRUNDO-OIL is completely safe and biodegradable and has no harmful affects onrubber air hoses.NOTE: In order to ensure adequate lubrication, tool lubricator must remain uprightduring while in use. Lubricator flow should be set at 0 when transporting.NOTE: <strong>Inc</strong>rease lubricator’s normal setting by 1 during cold weather conditions.D. Pit Description/ConstructionPipe ramming bore pits do not typically require the use of reinforced back abutmentsand are not restricted in the length or diameter of the product pipe sections that can beused. Bore pit preparations will, in part, be dictated by job site conditions and will varyby project.Generally, the bore pit needs to have a minimum length equal to the sum of themeasurements of the ramming tool, the ram cone, soil removal cone, the length of theproduct pipe sections being used, plus 5 feet of working space behind the tool(see Fig. 11).DANGER: Entrance & Exit Pits that are at least 3.93 feet (1.2 m) deep need tobe shored as necessary to comply with OSHA regulations and guard againstcollapse. Failure to do so could result in serious personal injury or death.E. Cradle/Adjustable Bearing StandThe adjustable bearing stand is a heavy-duty mechanism that provides both support andalignment for the GRUNDORAM and the pipe. An inflatable air bladder allows for easyvertical adjustment (see Fig. 16). It can lift over three tons and can also be fitted with aspecial height adapter (see Fig. 17). With the use of ratcheting web straps, the bearingstand can be pulled along with the GRUNDORAM while it is pushing the pipe (see Fig. 18).12 <strong>TT</strong> TECHNOLOGIES, INC.