Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

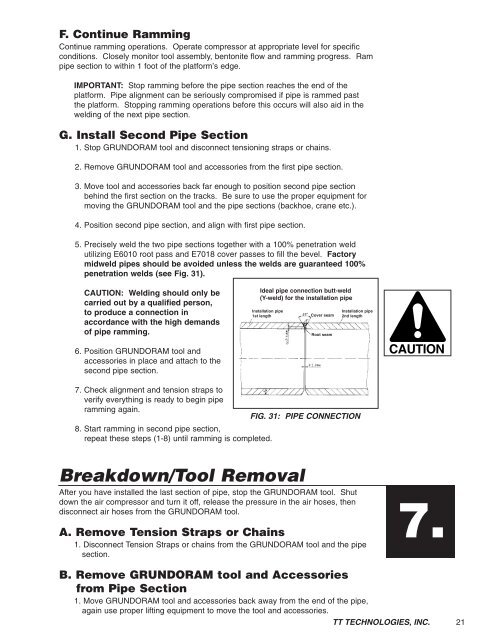

F. Continue RammingContinue ramming operations. Operate compressor at appropriate level for specificconditions. Closely monitor tool assembly, bentonite flow and ramming progress. Rampipe section to within 1 foot of the platform’s edge.IMPORTANT: Stop ramming before the pipe section reaches the end of theplatform. Pipe alignment can be seriously compromised if pipe is rammed pastthe platform. Stopping ramming operations before this occurs will also aid in thewelding of the next pipe section.G. Install Second Pipe Section1. Stop GRUNDORAM tool and disconnect tensioning straps or chains.2. Remove GRUNDORAM tool and accessories from the first pipe section.3. Move tool and accessories back far enough to position second pipe sectionbehind the first section on the tracks. Be sure to use the proper equipment formoving the GRUNDORAM tool and the pipe sections (backhoe, crane etc.).4. Position second pipe section, and align with first pipe section.5. Precisely weld the two pipe sections together with a 100% penetration weldutilizing E6010 root pass and E7018 cover passes to fill the bevel. Factorymidweld pipes should be avoided unless the welds are guaranteed 100%penetration welds (see Fig. 31).CAUTION: Welding should only becarried out by a qualified person,to produce a connection inaccordance with the high demandsof pipe ramming.Ideal pipe connection butt-weld(Y-weld) for the installation pipeInstallation pipe1st lengthCover seamRoot seamInstallation pipe2nd length6. Position GRUNDORAM tool andaccessories in place and attach to thesecond pipe section.7. Check alignment and tension straps toverify everything is ready to begin piperamming again.8. Start ramming in second pipe section,repeat these steps (1-8) until ramming is completed.FIG. 31: PIPE CONNECTIONBreakdown/Tool RemovalAfter you have installed the last section of pipe, stop the GRUNDORAM tool. Shutdown the air compressor and turn it off, release the pressure in the air hoses, thendisconnect air hoses from the GRUNDORAM tool.A. Remove Tension Straps or Chains1. Disconnect Tension Straps or chains from the GRUNDORAM tool and the pipesection.7.B. Remove GRUNDORAM tool and Accessoriesfrom Pipe Section1. Move GRUNDORAM tool and accessories back away from the end of the pipe,again use proper lifting equipment to move the tool and accessories.<strong>TT</strong> TECHNOLOGIES, INC.21