Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

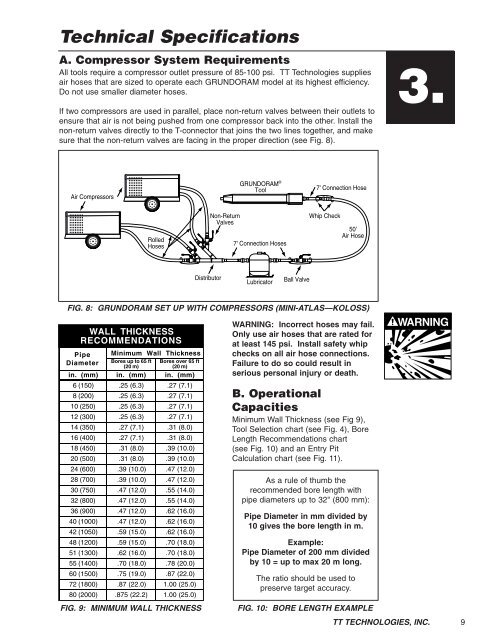

Technical SpecificationsA. Compressor System RequirementsAll tools require a compressor outlet pressure of 85-100 psi. <strong>TT</strong> <strong>Technologies</strong> suppliesair hoses that are sized to operate each GRUNDORAM model at its highest efficiency.Do not use smaller diameter hoses.If two compressors are used in parallel, place non-return valves between their outlets toensure that air is not being pushed from one compressor back into the other. Install thenon-return valves directly to the T-connector that joins the two lines together, and makesure that the non-return valves are facing in the proper direction (see Fig. 8).3.Air CompressorsGRUNDORAM ®Tool7' Connection HoseRolledHosesNon-ReturnValves7' Connection HosesWhip Check50'Air HoseDistributorLubricatorBall ValveFIG. 8: GRUNDORAM SET UP WITH COMPRESSORS (MINI-ATLAS—KOLOSS)WALL THICKNESSRECOMMENDATIONSPipe Minimum Wall ThicknessDiameter Bores up to 65 ft(20 m)Bores over 65 ft(20 m)in. (mm) in. (mm) in. (mm)6 (150) .25 (6.3) .27 (7.1)8 (200) .25 (6.3) .27 (7.1)10 (250) .25 (6.3) .27 (7.1)12 (300) .25 (6.3) .27 (7.1)14 (350) .27 (7.1) .31 (8.0)16 (400) .27 (7.1) .31 (8.0)18 (450) .31 (8.0) .39 (10.0)20 (500) .31 (8.0) .39 (10.0)24 (600) .39 (10.0) .47 (12.0)28 (700) .39 (10.0) .47 (12.0)30 (750) .47 (12.0) .55 (14.0)32 (800) .47 (12.0) .55 (14.0)36 (900) .47 (12.0) .62 (16.0)40 (1000) .47 (12.0) .62 (16.0)42 (1050) .59 (15.0) .62 (16.0)48 (1200) .59 (15.0) .70 (18.0)51 (1300) .62 (16.0) .70 (18.0)55 (1400) .70 (18.0) .78 (20.0)60 (1500) .75 (19.0) .87 (22.0)72 (1800) .87 (22.0) 1.00 (25.0)80 (2000) .875 (22.2) 1.00 (25.0)FIG. 9: MINIMUM WALL THICKNESSWARNING: <strong>Inc</strong>orrect hoses may fail.Only use air hoses that are rated forat least 145 psi. Install safety whipchecks on all air hose connections.Failure to do so could result inserious personal injury or death.B. OperationalCapacitiesMinimum Wall Thickness (see Fig 9),Tool Selection chart (see Fig. 4), BoreLength Recommendations chart(see Fig. 10) and an Entry PitCalculation chart (see Fig. 11).As a rule of thumb therecommended bore length withpipe diameters up to 32" (800 mm):Pipe Diameter in mm divided by10 gives the bore length in m.Example:Pipe Diameter of 200 mm dividedby 10 = up to max 20 m long.The ratio should be used topreserve target accuracy.FIG. 10: BORE LENGTH EXAMPLE<strong>TT</strong> TECHNOLOGIES, INC.9