Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

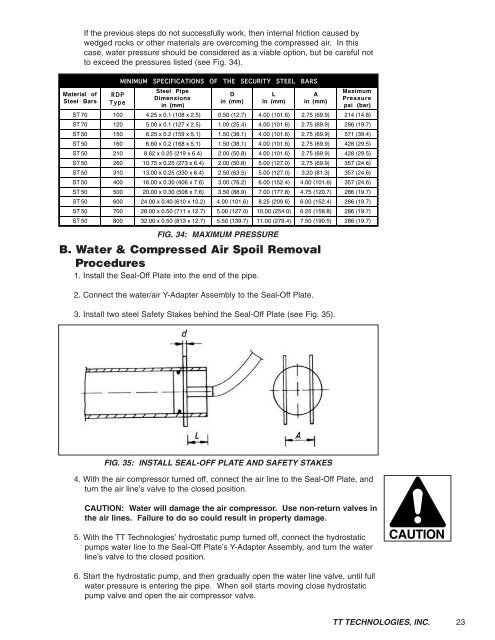

If the previous steps do not successfully work, then internal friction caused bywedged rocks or other materials are overcoming the compressed air. In thiscase, water pressure should be considered as a viable option, but be careful notto exceed the pressures listed (see Fig. 34).Material ofSteel BarsR D PT ypeMINIMUM SPECIFICATIONS OF THE SECURITY STEEL BARSSteel PipeDimensionsin (mm)Din (mm)Lin (mm)ST 70 100 4.25 x 0.1 (108 x 2.5) 0.50 (12.7) 4.00 (101.6) 2.75 (69.9) 214 (14.8)ST 70 120 5.00 x 0.1 (127 x 2.5) 1.00 (25.4) 4.00 (101.6) 2.75 (69.9) 286 (19.7)ST 50 150 6.25 x 0.2 (159 x 5.1) 1.50 (38.1) 4.00 (101.6) 2.75 (69.9) 571 (39.4)ST 50 160 6.60 x 0.2 (168 x 5.1) 1.50 (38.1) 4.00 (101.6) 2.75 (69.9) 428 (29.5)ST 50 210 8.62 x 0.25 (219 x 6.4) 2.00 (50.8) 4.00 (101.6) 2.75 (69.9) 428 (29.5)ST 50 260 10.75 x 0.25 (273 x 6.4) 2.00 (50.8) 5.00 (127.0) 2.75 (69.9) 357 (24.6)ST 50 310 13.00 x 0.25 (330 x 6.4) 2.50 (63.5) 5.00 (127.0) 3.20 (81.3) 357 (24.6)ST 50 400 16.00 x 0.30 (406 x 7.6) 3.00 (76.2) 6.00 (152.4) 4.00 (101.6) 357 (24.6)ST 50 500 20.00 x 0.30 (508 x 7.6) 3.50 (88.9) 7.00 (177.8) 4.75 (120.7) 286 (19.7)ST 50 600 24.00 x 0.40 (610 x 10.2) 4.00 (101.6) 8.25 (209.6) 6.00 (152.4) 286 (19.7)ST 50 700 28.00 x 0.50 (711 x 12.7) 5.00 (127.0) 10.00 (254.0) 6.25 (158.8) 286 (19.7)ST 50 800 32.00 x 0.50 (813 x 12.7) 5.50 (139.7) 11.00 (279.4) 7.50 (190.5) 286 (19.7)FIG. 34: MAXIMUM PRESSUREB. Water & Compressed Air Spoil RemovalProcedures1. Install the Seal-Off Plate into the end of the pipe.2. Connect the water/air Y-Adapter Assembly to the Seal-Off Plate.Ain (mm)3. Install two steel Safety Stakes behind the Seal-Off Plate (see Fig. 35).MaximumPressurepsi (bar)FIG. 35: INSTALL SEAL-OFF PLATE AND SAFETY STAKES4. With the air compressor turned off, connect the air line to the Seal-Off Plate, andturn the air line’s valve to the closed position.CAUTION: Water will damage the air compressor. Use non-return valves inthe air lines. Failure to do so could result in property damage.5. With the <strong>TT</strong> <strong>Technologies</strong>’ hydrostatic pump turned off, connect the hydrostaticpumps water line to the Seal-Off Plate’s Y-Adapter Assembly, and turn the waterline’s valve to the closed position.6. Start the hydrostatic pump, and then gradually open the water line valve, until fullwater pressure is entering the pipe. When soil starts moving close hydrostaticpump valve and open the air compressor valve.<strong>TT</strong> TECHNOLOGIES, INC.23