Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

Grundoram Manual (PDF 1.7MB) - TT Technologies Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

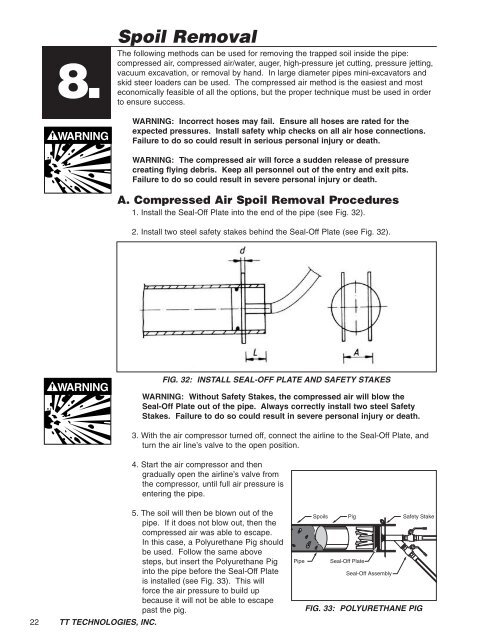

8.Spoil RemovalThe following methods can be used for removing the trapped soil inside the pipe:compressed air, compressed air/water, auger, high-pressure jet cutting, pressure jetting,vacuum excavation, or removal by hand. In large diameter pipes mini-excavators andskid steer loaders can be used. The compressed air method is the easiest and mosteconomically feasible of all the options, but the proper technique must be used in orderto ensure success.WARNING: <strong>Inc</strong>orrect hoses may fail. Ensure all hoses are rated for theexpected pressures. Install safety whip checks on all air hose connections.Failure to do so could result in serious personal injury or death.WARNING: The compressed air will force a sudden release of pressurecreating flying debris. Keep all personnel out of the entry and exit pits.Failure to do so could result in severe personal injury or death.A. Compressed Air Spoil Removal Procedures1. Install the Seal-Off Plate into the end of the pipe (see Fig. 32).2. Install two steel safety stakes behind the Seal-Off Plate (see Fig. 32).FIG. 32: INSTALL SEAL-OFF PLATE AND SAFETY STAKESWARNING: Without Safety Stakes, the compressed air will blow theSeal-Off Plate out of the pipe. Always correctly install two steel SafetyStakes. Failure to do so could result in severe personal injury or death.3. With the air compressor turned off, connect the airline to the Seal-Off Plate, andturn the air line’s valve to the open position.4. Start the air compressor and thengradually open the airline’s valve fromthe compressor, until full air pressure isentering the pipe.22 <strong>TT</strong> TECHNOLOGIES, INC.5. The soil will then be blown out of thepipe. If it does not blow out, then thecompressed air was able to escape.In this case, a Polyurethane Pig shouldbe used. Follow the same abovesteps, but insert the Polyurethane Piginto the pipe before the Seal-Off Plateis installed (see Fig. 33). This willforce the air pressure to build upbecause it will not be able to escapepast the pig.Spoils PigSafety StakePipe Seal-Off PlateSeal-Off AssemblyFIG. 33: POLYURETHANE PIG