4000 Switch Machine - Alstom

4000 Switch Machine - Alstom

4000 Switch Machine - Alstom

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

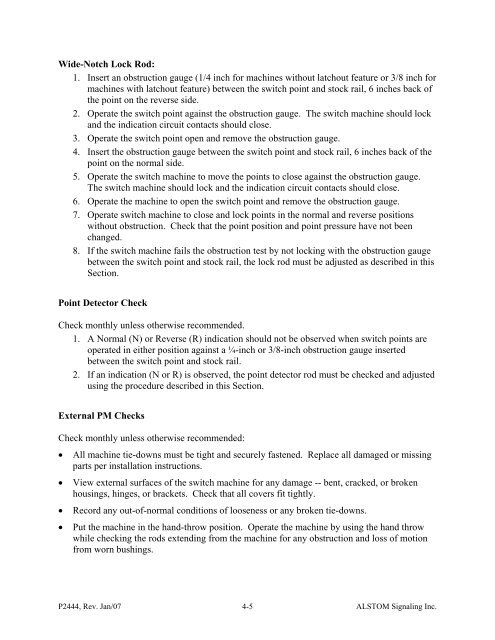

Wide-Notch Lock Rod:1. Insert an obstruction gauge (1/4 inch for machines without latchout feature or 3/8 inch formachines with latchout feature) between the switch point and stock rail, 6 inches back ofthe point on the reverse side.2. Operate the switch point against the obstruction gauge. The switch machine should lockand the indication circuit contacts should close.3. Operate the switch point open and remove the obstruction gauge.4. Insert the obstruction gauge between the switch point and stock rail, 6 inches back of thepoint on the normal side.5. Operate the switch machine to move the points to close against the obstruction gauge.The switch machine should lock and the indication circuit contacts should close.6. Operate the machine to open the switch point and remove the obstruction gauge.7. Operate switch machine to close and lock points in the normal and reverse positionswithout obstruction. Check that the point position and point pressure have not beenchanged.8. If the switch machine fails the obstruction test by not locking with the obstruction gaugebetween the switch point and stock rail, the lock rod must be adjusted as described in thisSection.Point Detector CheckCheck monthly unless otherwise recommended.1. A Normal (N) or Reverse (R) indication should not be observed when switch points areoperated in either position against a ¼-inch or 3/8-inch obstruction gauge insertedbetween the switch point and stock rail.2. If an indication (N or R) is observed, the point detector rod must be checked and adjustedusing the procedure described in this Section.External PM ChecksCheck monthly unless otherwise recommended:• All machine tie-downs must be tight and securely fastened. Replace all damaged or missingparts per installation instructions.• View external surfaces of the switch machine for any damage -- bent, cracked, or brokenhousings, hinges, or brackets. Check that all covers fit tightly.• Record any out-of-normal conditions of looseness or any broken tie-downs.• Put the machine in the hand-throw position. Operate the machine by using the hand throwwhile checking the rods extending from the machine for any obstruction and loss of motionfrom worn bushings.P2444, Rev. Jan/07 4-5ALSTOM Signaling Inc.