4000 Switch Machine - Alstom

4000 Switch Machine - Alstom

4000 Switch Machine - Alstom

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

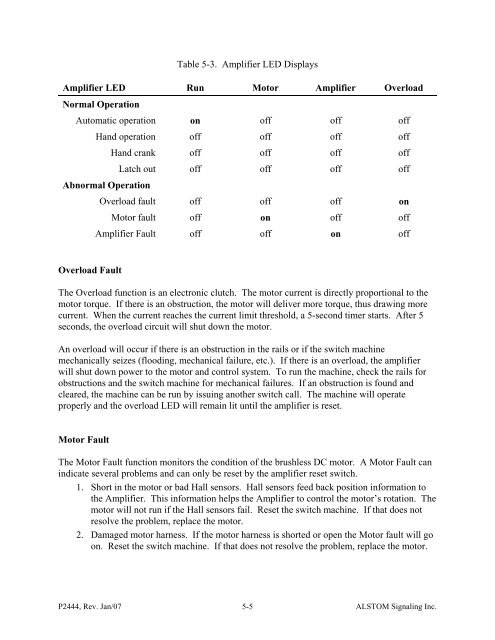

Table 5-3. Amplifier LED DisplaysAmplifier LED Run Motor Amplifier OverloadNormal OperationAutomatic operation on off off offHand operation off off off offHand crank off off off offLatch out off off off offAbnormal OperationOverload fault off off off onMotor fault off on off offAmplifier Fault off off on offOverload FaultThe Overload function is an electronic clutch. The motor current is directly proportional to themotor torque. If there is an obstruction, the motor will deliver more torque, thus drawing morecurrent. When the current reaches the current limit threshold, a 5-second timer starts. After 5seconds, the overload circuit will shut down the motor.An overload will occur if there is an obstruction in the rails or if the switch machinemechanically seizes (flooding, mechanical failure, etc.). If there is an overload, the amplifierwill shut down power to the motor and control system. To run the machine, check the rails forobstructions and the switch machine for mechanical failures. If an obstruction is found andcleared, the machine can be run by issuing another switch call. The machine will operateproperly and the overload LED will remain lit until the amplifier is reset.Motor FaultThe Motor Fault function monitors the condition of the brushless DC motor. A Motor Fault canindicate several problems and can only be reset by the amplifier reset switch.1. Short in the motor or bad Hall sensors. Hall sensors feed back position information tothe Amplifier. This information helps the Amplifier to control the motor’s rotation. Themotor will not run if the Hall sensors fail. Reset the switch machine. If that does notresolve the problem, replace the motor.2. Damaged motor harness. If the motor harness is shorted or open the Motor fault will goon. Reset the switch machine. If that does not resolve the problem, replace the motor.P2444, Rev. Jan/07 5-5ALSTOM Signaling Inc.