- Page 1 and 2:

Introduction to On BoardDiagnostics

- Page 3 and 4:

Introduction to On BoardDiagnostics

- Page 5 and 6:

Introduction to On BoardDiagnostics

- Page 7 and 8:

Introduction to On BoardDiagnostics

- Page 9 and 10:

OBD II monitors more components and

- Page 11 and 12:

Introduction to On BoardDiagnostics

- Page 13 and 14:

Introduction to On BoardDiagnostics

- Page 15 and 16:

Introduction to On BoardDiagnostics

- Page 17 and 18:

___________________________________

- Page 19 and 20:

Introduction to On BoardDiagnostics

- Page 21 and 22:

Introduction to On BoardDiagnostics

- Page 23 and 24:

Introduction to On BoardDiagnostics

- Page 25 and 26:

Powertrain and EmissionControls in

- Page 27 and 28:

Powertrain and EmissionControls in

- Page 29 and 30:

Powertrain and EmissionControls in

- Page 31 and 32:

Powertrain and EmissionControls in

- Page 33 and 34:

Powertrain and EmissionControl in P

- Page 35 and 36:

Powertrain and EmissionControls in

- Page 37 and 38:

Powertrain and EmissionControls in

- Page 39 and 40:

OBD II for L & MD VehiclesSTD Manua

- Page 41 and 42:

OBD II for L & MD VehiclesSTD Manua

- Page 43 and 44:

OBD II for L & MD VehiclesSTD Manua

- Page 45 and 46:

OBD II for L & MD VehiclesDiagnosti

- Page 47 and 48:

OBD II for L & MD VehiclesSTD Manua

- Page 49 and 50:

OBD II for L & MD VehiclesSTD Manua

- Page 51 and 52:

OBD II for L & MD VehiclesSTD Manua

- Page 53 and 54:

OBD II for L & MD VehiclesSTD Manua

- Page 55 and 56:

OBD II for L & MD VehiclesSTD Manua

- Page 57 and 58:

OBD II for L & MD VehiclesSTD Manua

- Page 59 and 60:

Fundamentals of PowertrainControl s

- Page 61 and 62:

The Freeze Frame can also be used f

- Page 63 and 64:

Fundamentals of PowertrainControl s

- Page 65 and 66: Evaporative System Monitoring: Hydr

- Page 67 and 68: OBD(II)In addition the electrical c

- Page 69 and 70: Fundamentals of PowertrainControl s

- Page 71 and 72: Fundamentals of PowertrainControl s

- Page 73 and 74: Fundamentals of PowertrainControl s

- Page 75 and 76: Fundamentals of PowertrainControl s

- Page 77 and 78: Fundamentals of PowertrainControl s

- Page 79 and 80: Fundamentals of PowertrainControl s

- Page 81 and 82: Fundamentals of PowertrainControl s

- Page 83 and 84: Fundamentals of PowertrainControl s

- Page 85 and 86: Fundamentals of PowertrainControl s

- Page 87 and 88: Fundamentals of PowertrainControl s

- Page 89 and 90: Fundamentals of PowertrainControl s

- Page 91 and 92: Fundamentals of PowertrainControl s

- Page 93 and 94: Fundamentals of PowertrainControl s

- Page 95 and 96: Fundamentals of PowertrainControl s

- Page 97 and 98: Fundamentals of PowertrainControl s

- Page 99 and 100: Fundamentals of PowertrainControl s

- Page 101 and 102: Fundamentals of PowertrainControl s

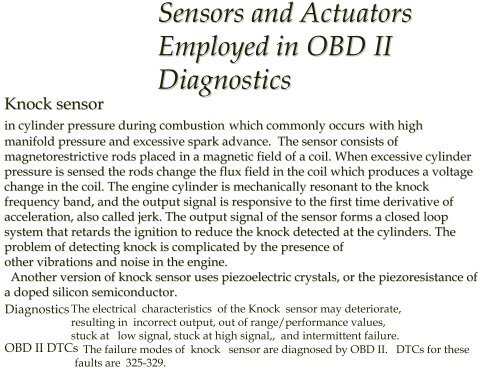

- Page 103 and 104: Sensors and ActuatorsEmployed in OB

- Page 105 and 106: Sensors and ActuatorsEmployed in OB

- Page 107 and 108: Sensors and ActuatorsEmployed in OB

- Page 109 and 110: Sensors and ActuatorsEmployed in OB

- Page 111 and 112: Sensors and ActuatorsEmployed in OB

- Page 113 and 114: Sensors and ActuatorsEmployed in OB

- Page 115: Sensors and ActuatorsEmployed in OB

- Page 119 and 120: Sensors and ActuatorsEmployed in OB

- Page 121 and 122: Sensors and ActuatorsEmployed in OB

- Page 123 and 124: Secondary air valvesSensors and Act

- Page 125 and 126: Sensors and ActuatorsEmployed in OB

- Page 127 and 128: Functionality of PowertrainControl

- Page 129 and 130: Functionality of PowertrainControl

- Page 131 and 132: Functionality of PowertrainControl

- Page 133 and 134: Functionality of PowertrainControl

- Page 135 and 136: Functionality of PowertrainControl

- Page 137 and 138: Functionality of PowertrainControl

- Page 139 and 140: Functionality of PowertrainControl

- Page 141 and 142: Functionality of PowertrainControl

- Page 143 and 144: Functionality of PowertrainControl

- Page 145 and 146: Functionality of PowertrainControl

- Page 147 and 148: Functionality of PowertrainControl