Introduction to On Board Diagnostics (II)

Introduction to On Board Diagnostics (II)

Introduction to On Board Diagnostics (II)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

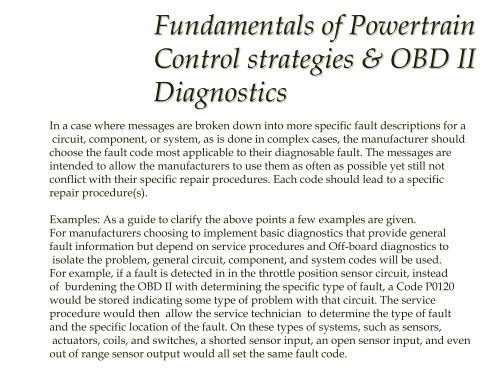

Fundamentals of PowertrainControl strategies & OBD <strong>II</strong><strong>Diagnostics</strong>In a case where messages are broken down in<strong>to</strong> more specific fault descriptions for acircuit, component, or system, as is done in complex cases, the manufacturer shouldchoose the fault code most applicable <strong>to</strong> their diagnosable fault. The messages areintended <strong>to</strong> allow the manufacturers <strong>to</strong> use them as often as possible yet still notconflict with their specific repair procedures. Each code should lead <strong>to</strong> a specificrepair procedure(s).Examples: As a guide <strong>to</strong> clarify the above points a few examples are given.For manufacturers choosing <strong>to</strong> implement basic diagnostics that provide generalfault information but depend on service procedures and Off-board diagnostics <strong>to</strong>isolate the problem, general circuit, component, and system codes will be used.For example, if a fault is detected in in the throttle position sensor circuit, insteadof burdening the OBD <strong>II</strong> with determining the specific type of fault, a Code P0120would be s<strong>to</strong>red indicating some type of problem with that circuit. The serviceprocedure would then allow the service technician <strong>to</strong> determine the type of faultand the specific location of the fault. <strong>On</strong> these types of systems, such as sensors,actua<strong>to</strong>rs, coils, and switches, a shorted sensor input, an open sensor input, and evenout of range sensor output would all set the same fault code.