Introduction to On Board Diagnostics (II)

Introduction to On Board Diagnostics (II)

Introduction to On Board Diagnostics (II)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

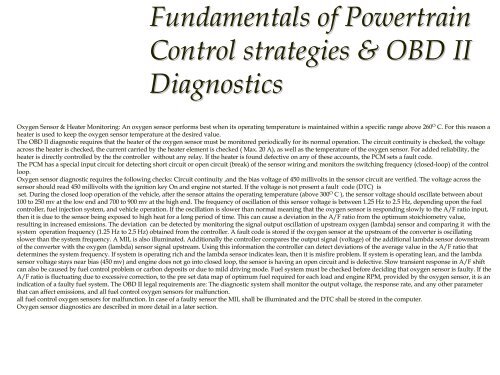

Fundamentals of PowertrainControl strategies & OBD <strong>II</strong><strong>Diagnostics</strong>Oxygen Sensor & Heater Moni<strong>to</strong>ring: An oxygen sensor performs best t when its operating temperature is maintained within a specific range above 260 O C. For this reason aheater is used <strong>to</strong> keep the oxygen sensor temperature at the desired value.The OBD <strong>II</strong> diagnostic requires that the heater of the oxygen sensor sor must be moni<strong>to</strong>red periodically for its normal operation. The circuit continuity is checked, the voltageacross the heater is checked, the current carried by the heater element is checked ( Max. 20 A), as well as the temperature of the <strong>to</strong>xygen sensor. For added reliability, theheater is directly controlled by the the controller without any relay. If the heater is found defective on any of these accounts, the PCM sets a fault code.The PCM has a special input circuit for detecting short circuit or open circuit (break) of the sensor wiring and moni<strong>to</strong>rs the switching frequency (closed-loop) loop) of the controlloop.Oxygen sensor diagnostic requires the following checks: Circuit continuity ,and the bias voltage of 450 millivolts in the sensor circuit are verified. The voltage across thesensor should read 450 millivolts with the ignition key <strong>On</strong> and engine not started. If the voltage is not present a fault code (DTC) isset. During the closed loop operation of the vehicle, after the sensor attains the operating temperature (above 300 O C ), the sensor voltage should oscillate between about100 <strong>to</strong> 250 mv at the low end and 700 <strong>to</strong> 900 mv at the high end. The frequency of oscillation of this sensor voltage is between 1.25 Hz <strong>to</strong> 2.5 Hz, depending upon the fuelcontroller, fuel injection system, and vehicle operation. If the oscillation is slower than normal meaning that the oxygen sensor r is responding slowly <strong>to</strong> the A/F ratio input,then it is due <strong>to</strong> the sensor being exposed <strong>to</strong> high heat for a long period of time. This can cause a deviation in the A/F ratio from fthe optimum s<strong>to</strong>ichiometry value,resulting in increased emissions. The deviation can be detected by moni<strong>to</strong>ring the signal output oscillation of upstream oxygen (lambda) sensor and comparing it with thesystem operation frequency (1.25 Hz <strong>to</strong> 2.5 Hz) obtained from the e controller. A fault code is s<strong>to</strong>red if the oxygen sensor at the upstream of the converter is oscillatingslower than the system frequency. A MIL is also illuminated. Additionally the controller compares the output signal (voltage) of the additional lambda sensor downstreamof the converter with the oxygen (lambda) sensor signal upstream. . Using this information the controller can detect deviations of the average value in the A/F ratio thatdetermines the system frequency. If system is operating rich and the lambda sensor indicates lean, then it is misfire problem. If system is operating lean, and the lambdasensor voltage stays near bias (450 mv) ) and engine does not go in<strong>to</strong> closed loop, the sensor is having an open circuit and is defective. Slow transient response in A/F shiftcan also be caused by fuel control problem or carbon deposits or due <strong>to</strong> mild driving mode. Fuel system must be checked before deciding that oxygen sensor is faulty. If theA/F ratio is fluctuating due <strong>to</strong> excessive correction, <strong>to</strong> the pre set data map of optimum fuel required for each load and engine RPM, provided by the oxygen sensor, it is anindication of a faulty fuel system. The OBD <strong>II</strong> legal requirements s are: The diagnostic system shall moni<strong>to</strong>r the output voltage, the tresponse rate, and any other parameterthat can affect emissions, and all fuel control oxygen sensors for fmalfunction.all fuel control oxygen sensors for malfunction. In case of a faulty sensor the MIL shall be illuminated and the DTC shall be s<strong>to</strong>red in the computer.Oxygen sensor diagnostics are described in more detail in a later r section.