SleepTech September - October 2018

SleepTech September - October 2018

SleepTech September - October 2018

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

113<br />

•Can Be Used to Tailor Adhesive<br />

to Application<br />

• Faster Set Time<br />

•Reduce Amount of Material to<br />

Cool<br />

•Reduce Force to Compress<br />

•Shorten Set Time (up<br />

to 4 times)<br />

•Increase Process<br />

Speeds<br />

•Increased Volume<br />

•Up to 2 Times Increase<br />

in Volume<br />

•Less Sagging – Keep<br />

Adhesive Where It Is<br />

Wanted<br />

•Greater Gap Filling –<br />

Consistent<br />

•Application on “Non-<br />

Smooth” Substrates<br />

•Better Substrate Penetration<br />

• Lower Heat Density<br />

•Foaming Reduces<br />

Heat Density of Adhesive<br />

•Lower Heat Density<br />

Reduces Deformities<br />

•in Flexible Packaging Substrates<br />

•Expands Use of Current/New<br />

Adhesives in<br />

•Growth Market<br />

•Improved Operator Safety<br />

• Less Force to Apply<br />

•Gas “Plasticizes” Adhesive<br />

Making It Easy to Spread<br />

•Can be Utilized with Various<br />

Dispensing Options (Even Extruded<br />

Materials)<br />

•Applicable for Delicate Substrates<br />

• Material Savings; Reducing the<br />

Density of Material Means:<br />

•Lower Material Cost<br />

•Less Part Weight/Shipping Cost<br />

•Less Process Energy<br />

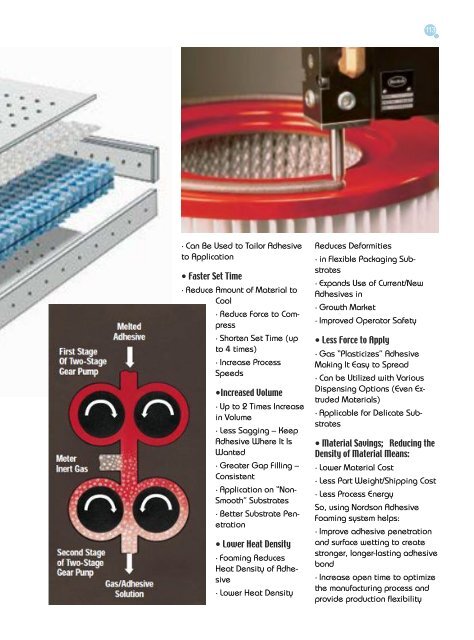

So, using Nordson Adhesive<br />

Foaming system helps:<br />

•Improve adhesive penetration<br />

and surface wetting to create<br />

stronger, longer-lasting adhesive<br />

bond<br />

•Increase open time to optimize<br />

the manufacturing process and<br />

provide production flexibility