Final report for WP4.3: Enhancement of design methods ... - Upwind

Final report for WP4.3: Enhancement of design methods ... - Upwind

Final report for WP4.3: Enhancement of design methods ... - Upwind

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

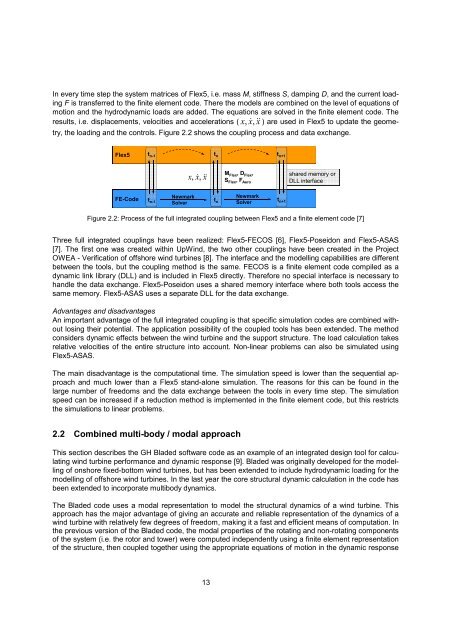

In every time step the system matrices <strong>of</strong> Flex5, i.e. mass M, stiffness S, damping D, and the current loading<br />

F is transferred to the finite element code. There the models are combined on the level <strong>of</strong> equations <strong>of</strong><br />

motion and the hydrodynamic loads are added. The equations are solved in the finite element code. The<br />

results, i.e. displacements, velocities and accelerations ( x, x&,<br />

&x<br />

&)<br />

are used in Flex5 to update the geometry,<br />

the loading and the controls. Figure 2.2 shows the coupling process and data exchange.<br />

Flex5<br />

FE-Code<br />

t n-1<br />

t n-1<br />

Newmark<br />

Solver<br />

x, x& , && x<br />

13<br />

t n<br />

t n<br />

M Flex , D Flex ,<br />

S Flex, F Aero<br />

Newmark<br />

Solver<br />

t n+1<br />

t n+1<br />

shared memory or<br />

DLL interface<br />

Figure 2.2: Process <strong>of</strong> the full integrated coupling between Flex5 and a finite element code [7]<br />

Three full integrated couplings have been realized: Flex5-FECOS [6], Flex5-Poseidon and Flex5-ASAS<br />

[7]. The first one was created within UpWind, the two other couplings have been created in the Project<br />

OWEA - Verification <strong>of</strong> <strong>of</strong>fshore wind turbines [8]. The interface and the modelling capabilities are different<br />

between the tools, but the coupling method is the same. FECOS is a finite element code compiled as a<br />

dynamic link library (DLL) and is included in Flex5 directly. There<strong>for</strong>e no special interface is necessary to<br />

handle the data exchange. Flex5-Poseidon uses a shared memory interface where both tools access the<br />

same memory. Flex5-ASAS uses a separate DLL <strong>for</strong> the data exchange.<br />

Advantages and disadvantages<br />

An important advantage <strong>of</strong> the full integrated coupling is that specific simulation codes are combined without<br />

losing their potential. The application possibility <strong>of</strong> the coupled tools has been extended. The method<br />

considers dynamic effects between the wind turbine and the support structure. The load calculation takes<br />

relative velocities <strong>of</strong> the entire structure into account. Non-linear problems can also be simulated using<br />

Flex5-ASAS.<br />

The main disadvantage is the computational time. The simulation speed is lower than the sequential approach<br />

and much lower than a Flex5 stand-alone simulation. The reasons <strong>for</strong> this can be found in the<br />

large number <strong>of</strong> freedoms and the data exchange between the tools in every time step. The simulation<br />

speed can be increased if a reduction method is implemented in the finite element code, but this restricts<br />

the simulations to linear problems.<br />

2.2 Combined multi-body / modal approach<br />

This section describes the GH Bladed s<strong>of</strong>tware code as an example <strong>of</strong> an integrated <strong>design</strong> tool <strong>for</strong> calculating<br />

wind turbine per<strong>for</strong>mance and dynamic response [9]. Bladed was originally developed <strong>for</strong> the modelling<br />

<strong>of</strong> onshore fixed-bottom wind turbines, but has been extended to include hydrodynamic loading <strong>for</strong> the<br />

modelling <strong>of</strong> <strong>of</strong>fshore wind turbines. In the last year the core structural dynamic calculation in the code has<br />

been extended to incorporate multibody dynamics.<br />

The Bladed code uses a modal representation to model the structural dynamics <strong>of</strong> a wind turbine. This<br />

approach has the major advantage <strong>of</strong> giving an accurate and reliable representation <strong>of</strong> the dynamics <strong>of</strong> a<br />

wind turbine with relatively few degrees <strong>of</strong> freedom, making it a fast and efficient means <strong>of</strong> computation. In<br />

the previous version <strong>of</strong> the Bladed code, the modal properties <strong>of</strong> the rotating and non-rotating components<br />

<strong>of</strong> the system (i.e. the rotor and tower) were computed independently using a finite element representation<br />

<strong>of</strong> the structure, then coupled together using the appropriate equations <strong>of</strong> motion in the dynamic response