WINTER 2024

Distributor's Link Magazine Winter 2024 / Vol 47 No 1

Distributor's Link Magazine Winter 2024 / Vol 47 No 1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

110<br />

THE DISTRIBUTOR’S LINK<br />

PENN ENGINEERING NEW FASTENING INNOVATIONS FOR CASTINGS AND SOFT METALS from page 38<br />

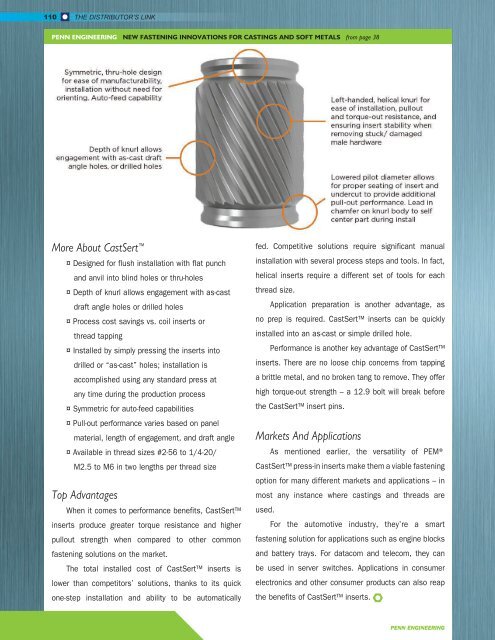

More About CastSert <br />

¤ Designed for flush installation with flat punch<br />

and anvil into blind holes or thru-holes<br />

¤ Depth of knurl allows engagement with as-cast<br />

draft angle holes or drilled holes<br />

¤ Process cost savings vs. coil inserts or<br />

thread tapping<br />

¤ Installed by simply pressing the inserts into<br />

drilled or “as-cast” holes; installation is<br />

accomplished using any standard press at<br />

any time during the production process<br />

¤ Symmetric for auto-feed capabilities<br />

¤ Pull-out performance varies based on panel<br />

material, length of engagement, and draft angle<br />

¤ Available in thread sizes #2-56 to 1/4-20/<br />

M2.5 to M6 in two lengths per thread size<br />

Top Advantages<br />

When it comes to performance benefits, CastSert<br />

inserts produce greater torque resistance and higher<br />

pullout strength when compared to other common<br />

fastening solutions on the market.<br />

The total installed cost of CastSert inserts is<br />

lower than competitors’ solutions, thanks to its quick<br />

one-step installation and ability to be automatically<br />

fed. Competitive solutions require significant manual<br />

installation with several process steps and tools. In fact,<br />

helical inserts require a different set of tools for each<br />

thread size.<br />

Application preparation is another advantage, as<br />

no prep is required. CastSert inserts can be quickly<br />

installed into an as-cast or simple drilled hole.<br />

Performance is another key advantage of CastSert<br />

inserts. There are no loose chip concerns from tapping<br />

a brittle metal, and no broken tang to remove. They offer<br />

high torque-out strength – a 12.9 bolt will break before<br />

the CastSert insert pins.<br />

Markets And Applications<br />

As mentioned earlier, the versatility of PEM®<br />

CastSert press-in inserts make them a viable fastening<br />

option for many different markets and applications – in<br />

most any instance where castings and threads are<br />

used.<br />

For the automotive industry, they’re a smart<br />

fastening solution for applications such as engine blocks<br />

and battery trays. For datacom and telecom, they can<br />

be used in server switches. Applications in consumer<br />

electronics and other consumer products can also reap<br />

the benefits of CastSert inserts.<br />

PENN ENGINEERING