WINTER 2024

Distributor's Link Magazine Winter 2024 / Vol 47 No 1

Distributor's Link Magazine Winter 2024 / Vol 47 No 1

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

90<br />

THE DISTRIBUTOR’S LINK<br />

ROB LaPOINTE CASE-HARDENING – CREATING FASTENERS WITH A DURABLE SKIN & FLEXIBLE CORE from page 8<br />

You may be wondering why durability and flexibility are<br />

contrasting features. Let’s take a moment to explain the<br />

relationship between durability and flexibility in carbon<br />

steel. When we think of durability, we think of something<br />

that resists change. “A diamond is forever” as De Beers<br />

says. Diamonds may not last forever, but they are very<br />

durable. The durability of diamonds is due to their<br />

hardness and resistance to corrosion. The durability of<br />

carbon steel is also related to its hardness. The harder<br />

the steel, the more durable it is. The harder the steel, the<br />

greater its resistance to being scratched or bent. Along<br />

with this durability due to hardness, comes brittleness.<br />

Brittleness is the tendency to break rather than bend.<br />

High hardness steel can withstand high forces and not<br />

bend or change shape, but when it reaches its breaking<br />

point, it fails by fracture without much bending. This is<br />

why high hardness is desirable in steel that is required<br />

to cut and shape other materials or in parts that must<br />

move against one another with minimum wear.<br />

The harder the steel, the greater its resistance to<br />

being scratched or bent. Along with this durability due to<br />

hardness, comes brittleness. Brittleness is the tendency<br />

to break rather than bend. High hardness steel can<br />

withstand high forces and not bend or change shape,<br />

but when it reaches its breaking point, it fails by fracture<br />

without much bending. This is why high hardness is<br />

desirable in steel that is required to cut and shape other<br />

materials or in parts that must move against one another<br />

with minimum wear.<br />

FIGURE 4. A MAN PULLING TAFFY, SHOWING ITS DUCTILE NATURE<br />

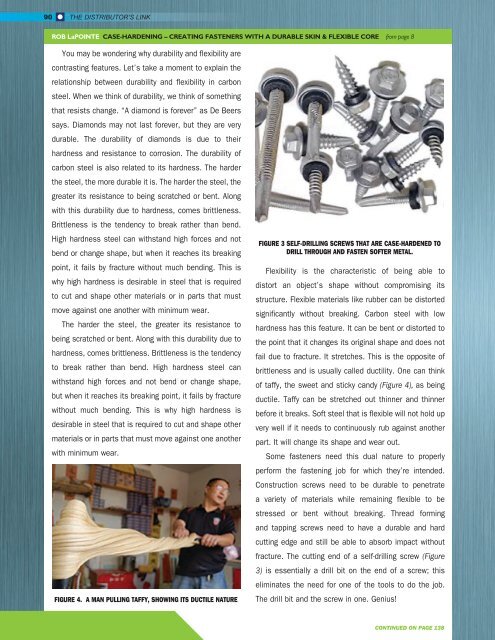

FIGURE 3 SELF-DRILLING SCREWS THAT ARE CASE-HARDENED TO<br />

DRILL THROUGH AND FASTEN SOFTER METAL.<br />

Flexibility is the characteristic of being able to<br />

distort an object’s shape without compromising its<br />

structure. Flexible materials like rubber can be distorted<br />

significantly without breaking. Carbon steel with low<br />

hardness has this feature. It can be bent or distorted to<br />

the point that it changes its original shape and does not<br />

fail due to fracture. It stretches. This is the opposite of<br />

brittleness and is usually called ductility. One can think<br />

of taffy, the sweet and sticky candy (Figure 4), as being<br />

ductile. Taffy can be stretched out thinner and thinner<br />

before it breaks. Soft steel that is flexible will not hold up<br />

very well if it needs to continuously rub against another<br />

part. It will change its shape and wear out.<br />

Some fasteners need this dual nature to properly<br />

perform the fastening job for which they’re intended.<br />

Construction screws need to be durable to penetrate<br />

a variety of materials while remaining flexible to be<br />

stressed or bent without breaking. Thread forming<br />

and tapping screws need to have a durable and hard<br />

cutting edge and still be able to absorb impact without<br />

fracture. The cutting end of a self-drilling screw (Figure<br />

3) is essentially a drill bit on the end of a screw; this<br />

eliminates the need for one of the tools to do the job.<br />

The drill bit and the screw in one. Genius!<br />

CONTINUED ON PAGE 138