262 Reverse Engineering <strong>–</strong> Recent Advances <strong>and</strong> Applications 20 Will-be-set-by-IN-TECH [2] Carslaw, H.S., <strong>and</strong> Jaeger, J.C. (2000). Conduction of Heat in Solids, Oxford University Press Inc., New York, NY. [3] Comroe, J.H. (1962). The lung; clinical physiology <strong>and</strong> pulmonary function tests, Year Book Medical Publishers, Chicago, IL. [4] Felici, M. <strong>and</strong> Filoche, M. <strong>and</strong> Sapoval, B. (2003). Diffusional screening in the human pulmonary acinus. J. Appl. Physiol., Vol. 94, pp. 2010. [5] Felici, M. <strong>and</strong> Filoche, M. <strong>and</strong> Sapoval, B. (2004). Renormalized R<strong>and</strong>om Walk Study of Oxygen Absorption in the Human Lung. Phys. Rev. Lett., Vol. 92, pp.068101. [6] Gheorghiu, S., <strong>and</strong> Coppens, M.-O. (2004). Optimal bimodal pore networks for heterogeneous catalysis. AIChE J., Vol. 50, pp. 812. [7] Grebenkov, D. S. <strong>and</strong> Filoche, M. <strong>and</strong> Sapoval, B. <strong>and</strong> Felici, M. (2005). Diffusion-Reaction in Branched Structures: Theory <strong>and</strong> Application to the Lung Acinus. Phys. Rev. Lett., Vol. 94, pp. 050602. [8] Haefeli-Bleuer, B., <strong>and</strong> Weibel, E.R. (1998). Morphometry of the human pulmonary acinus Anat. Rec., Vol. 220, pp. 401. [9] Hou, C. (2005). Scaling laws for oxygen transport across the space-filling system of respiratory membranes in the human lung, PhD thesis, University of Missouri, Columbia, MO. [10] Hou, C., Gheorghiu, S., Huxley, V.H., <strong>and</strong> Pfeifer, P. (2010). Reverse Engineering of Oxygen Transport in the Lung: Adaptation to Changing Dem<strong>and</strong>s <strong>and</strong> Resources through Space-Filling Networks. PLoS Comput. Biol., Vol. 6, No. 8, pp. e1000902. [11] Kjelstrup, S., Coppens, M.-O., Pharoah, J.G., <strong>and</strong> Pfeifer, P. (2010). Nature-Inspired Energy- <strong>and</strong> Material-Efficient Design of a Polymer Electrolyte Membrane Fuel Cell. Energy Fuels, Vol. 24, pp. 5097. [12] Mayo, M. (2009). Hierarchical Model of Gas-Exchange within the Acinar Airways of the Human Lung, PhD thesis, University of Missouri, Columbia, MO. [13] Mayo, M. Gheorghiu, S., <strong>and</strong> Pfeifer, P. (2011). Diffusional Screening in Treelike Spaces: an Exactly Solvable Diffusion-Reaction Model, Submitted. [14] M<strong>and</strong>elbrot, B. (1982). The Fractal Geometry of Nature, W.H. Freeman, USA. [15] Needham, T. (2007). Visual Complex Analysis, Oxford University Press, USA. [16] Pfeifer, P., <strong>and</strong> Sapoval, B. (1995). Optimization of diffusive transport to irregular surfaces with low sticking probability. Mat. Res. Soc. Symp. Proc., Vol. 366, pp. 271. [17] Sapoval, B., Filoche, M., <strong>and</strong> Weibel, E.R. (2002). Smaller is better<strong>–</strong>but not too small: A physical scale for the design of the mammalian pulmonary acinus. Proc. Natl. Acad. Sci. USA, Vol. 99, No. 16, pp. 10411. [18] Weibel, E.R. (1984). The Pathway for Oxygen, Harvard University Press, Cambridge, MA. [19] Weibel, E.R., Taylor, C.R., <strong>and</strong> Hoppeler, H. (1992). Variations in function <strong>and</strong> design: Testing symmorphosis in the respiratory system. PLoS Comp. Biol., Vol. 6, No. 8, pp. e1000902 [20] Weibel, E.R., Sapoval, B., <strong>and</strong> Filoche, M. (2005). Design of peripheral airways for efficient gas exchange. Respir. Physiol. Neurobiol., Vol. 148, pp. 3.

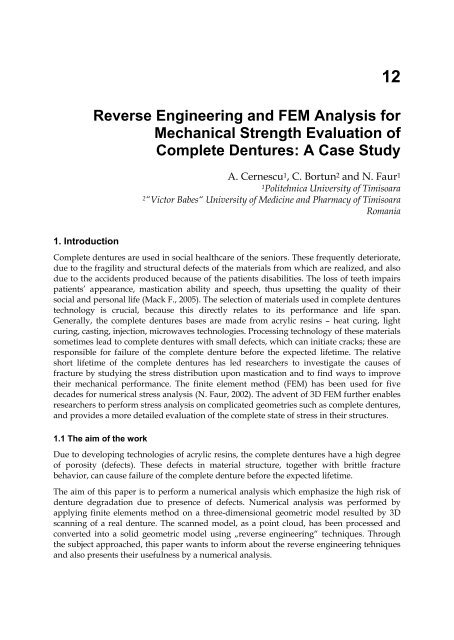

1. Introduction 12 Reverse Engineering <strong>and</strong> FEM Analysis for Mechanical Strength Evaluation of Complete Dentures: A Case Study A. Cernescu 1, C. Bortun 2 <strong>and</strong> N. Faur 1 1 Politehnica University of Timisoara 2 “Victor Babes“ University of Medicine <strong>and</strong> Pharmacy of Timisoara Romania Complete dentures are used in social healthcare of the seniors. These frequently deteriorate, due to the fragility <strong>and</strong> structural defects of the materials from which are realized, <strong>and</strong> also due to the accidents produced because of the patients disabilities. The loss of teeth impairs patients’ appearance, mastication ability <strong>and</strong> speech, thus upsetting the quality of their social <strong>and</strong> personal life (Mack F., 2005). The selection of materials used in complete dentures technology is crucial, because this directly relates to its performance <strong>and</strong> life span. Generally, the complete dentures bases are made from acrylic resins <strong>–</strong> heat curing, light curing, casting, injection, microwaves technologies. Processing technology of these materials sometimes lead to complete dentures with small defects, which can initiate cracks; these are responsible for failure of the complete denture before the expected lifetime. The relative short lifetime of the complete dentures has led researchers to investigate the causes of fracture by studying the stress distribution upon mastication <strong>and</strong> to find ways to improve their mechanical performance. The finite element method (FEM) has been used for five decades for numerical stress analysis (N. Faur, 2002). The advent of 3D FEM further enables researchers to perform stress analysis on complicated geometries such as complete dentures, <strong>and</strong> provides a more detailed evaluation of the complete state of stress in their structures. 1.1 The aim of the work Due to developing technologies of acrylic resins, the complete dentures have a high degree of porosity (defects). These defects in material structure, together with brittle fracture behavior, can cause failure of the complete denture before the expected lifetime. The aim of this paper is to perform a numerical analysis which emphasize the high risk of denture degradation due to presence of defects. Numerical analysis was performed by applying finite elements method on a three-dimensional geometric model resulted by 3D scanning of a real denture. The scanned model, as a point cloud, has been processed <strong>and</strong> converted into a solid geometric model using „<strong>reverse</strong> <strong>engineering</strong>“ techniques. Through the subject approached, this paper wants to inform about the <strong>reverse</strong> <strong>engineering</strong> tehniques <strong>and</strong> also presents their usefulness by a numerical analysis.

- Page 1 and 2:

REVERSE ENGINEERING - RECENT ADVANC

- Page 5 and 6:

Contents Preface IX Part 1 Software

- Page 9 and 10:

Preface Introduction In the recent

- Page 11 and 12:

Preface XI and con’s related to t

- Page 13 and 14:

Preface XIII the step-by-step appli

- Page 17:

Part 1 Software Reverse Engineering

- Page 20 and 21:

4 Reverse Engineering - Recent Adva

- Page 22 and 23:

6 Reverse Engineering - Recent Adva

- Page 24 and 25:

8 Reverse Engineering - Recent Adva

- Page 26 and 27:

10 Reverse Engineering - Recent Adv

- Page 28 and 29:

12 Reverse Engineering - Recent Adv

- Page 30 and 31:

14 Reverse Engineering - Recent Adv

- Page 32 and 33:

16 Reverse Engineering - Recent Adv

- Page 34 and 35:

18 Reverse Engineering - Recent Adv

- Page 36 and 37:

20 Reverse Engineering - Recent Adv

- Page 38 and 39:

22 Reverse Engineering - Recent Adv

- Page 40 and 41:

24 Reverse Engineering - Recent Adv

- Page 42 and 43:

26 Reverse Engineering - Recent Adv

- Page 44 and 45:

28 Reverse Engineering - Recent Adv

- Page 46 and 47:

30 Reverse Engineering - Recent Adv

- Page 48 and 49:

32 Reverse Engineering - Recent Adv

- Page 50 and 51:

34 Reverse Engineering - Recent Adv

- Page 52 and 53:

36 Reverse Engineering - Recent Adv

- Page 54 and 55:

38 Reverse Engineering - Recent Adv

- Page 56 and 57:

40 Reverse Engineering - Recent Adv

- Page 58 and 59:

42 Reverse Engineering - Recent Adv

- Page 60 and 61:

44 Reverse Engineering - Recent Adv

- Page 62 and 63:

46 Reverse Engineering - Recent Adv

- Page 64 and 65:

48 Reverse Engineering - Recent Adv

- Page 66 and 67:

50 Reverse Engineering - Recent Adv

- Page 68 and 69:

52 Reverse Engineering - Recent Adv

- Page 70 and 71:

54 Reverse Engineering - Recent Adv

- Page 72 and 73:

56 Reverse Engineering - Recent Adv

- Page 74 and 75:

58 2. Model driven architecture: An

- Page 76 and 77:

60 Reverse Engineering - Recent Adv

- Page 78 and 79:

62 Fig. 1. Model, metamodels and tr

- Page 80 and 81:

64 Reverse Engineering - Recent Adv

- Page 82 and 83:

66 Reverse Engineering - Recent Adv

- Page 84 and 85:

68 Reverse Engineering - Recent Adv

- Page 86 and 87:

70 Reverse Engineering - Recent Adv

- Page 88 and 89:

72 Reverse Engineering - Recent Adv

- Page 90 and 91:

74 Reverse Engineering - Recent Adv

- Page 92 and 93:

76 Reverse Engineering - Recent Adv

- Page 94 and 95:

78 Reverse Engineering - Recent Adv

- Page 96 and 97:

80 Reverse Engineering - Recent Adv

- Page 98 and 99:

82 Reverse Engineering - Recent Adv

- Page 100 and 101:

84 Reverse Engineering - Recent Adv

- Page 102 and 103:

86 Reverse Engineering - Recent Adv

- Page 104 and 105:

88 Reverse Engineering - Recent Adv

- Page 106 and 107:

90 Reverse Engineering - Recent Adv

- Page 108 and 109:

92 Reverse Engineering - Recent Adv

- Page 110 and 111:

94 Reverse Engineering - Recent Adv

- Page 112 and 113:

96 Reverse Engineering - Recent Adv

- Page 114 and 115:

98 Reverse Engineering - Recent Adv

- Page 116 and 117:

100 Reverse Engineering - Recent Ad

- Page 118 and 119:

102 Reverse Engineering - Recent Ad

- Page 120 and 121:

104 Reverse Engineering - Recent Ad

- Page 122 and 123:

106 Reverse Engineering - Recent Ad

- Page 124 and 125:

108 Table 1. Number of smoothers an

- Page 126 and 127:

110 Reverse Engineering - Recent Ad

- Page 128 and 129:

112 Reverse Engineering - Recent Ad

- Page 130 and 131:

114 Reverse Engineering - Recent Ad

- Page 133 and 134:

1. Introduction 60 Surface Reconstr

- Page 135 and 136:

Surface Reconstruction from Unorgan

- Page 137 and 138:

Surface Reconstruction from Unorgan

- Page 139 and 140:

Surface Reconstruction from Unorgan

- Page 141 and 142:

Surface Reconstruction from Unorgan

- Page 143 and 144:

Surface Reconstruction from Unorgan

- Page 145 and 146:

Surface Reconstruction from Unorgan

- Page 147 and 148:

Surface Reconstruction from Unorgan

- Page 149 and 150:

1. Introduction A Systematic Approa

- Page 151 and 152:

A Systematic Approach for Geometric

- Page 153 and 154:

A Systematic Approach for Geometric

- Page 155 and 156:

A Systematic Approach for Geometric

- Page 157 and 158:

A Systematic Approach for Geometric

- Page 159 and 160:

A Systematic Approach for Geometric

- Page 161 and 162:

A Systematic Approach for Geometric

- Page 163 and 164:

A Systematic Approach for Geometric

- Page 165 and 166:

A Systematic Approach for Geometric

- Page 167 and 168:

A Systematic Approach for Geometric

- Page 169 and 170:

A Systematic Approach for Geometric

- Page 171 and 172:

A Systematic Approach for Geometric

- Page 173 and 174:

A Systematic Approach for Geometric

- Page 175 and 176:

A Systematic Approach for Geometric

- Page 177 and 178:

A Review on Shape Engineering and D

- Page 179 and 180:

A Review on Shape Engineering and D

- Page 181 and 182:

A Review on Shape Engineering and D

- Page 183 and 184:

A Review on Shape Engineering and D

- Page 185 and 186:

A Review on Shape Engineering and D

- Page 187 and 188:

A Review on Shape Engineering and D

- Page 189 and 190:

A Review on Shape Engineering and D

- Page 191 and 192:

A Review on Shape Engineering and D

- Page 193 and 194:

A Review on Shape Engineering and D

- Page 195 and 196:

A Review on Shape Engineering and D

- Page 197 and 198:

A Review on Shape Engineering and D

- Page 199 and 200:

A Review on Shape Engineering and D

- Page 201 and 202:

A Review on Shape Engineering and D

- Page 203 and 204:

Integrating Reverse Engineering and

- Page 205 and 206:

Integrating Reverse Engineering and

- Page 207 and 208:

Integrating Reverse Engineering and

- Page 209 and 210:

Integrating Reverse Engineering and

- Page 211 and 212:

Integrating Reverse Engineering and

- Page 213 and 214:

Integrating Reverse Engineering and

- Page 215 and 216:

Integrating Reverse Engineering and

- Page 217 and 218:

Integrating Reverse Engineering and

- Page 219 and 220:

Integrating Reverse Engineering and

- Page 221 and 222:

Integrating Reverse Engineering and

- Page 223 and 224:

Integrating Reverse Engineering and

- Page 225 and 226:

Integrating Reverse Engineering and

- Page 227 and 228: Integrating Reverse Engineering and

- Page 229 and 230: Integrating Reverse Engineering and

- Page 231: Part 3 Reverse Engineering in Medic

- Page 234 and 235: 218 Reverse Engineering - Recent Ad

- Page 236 and 237: 220 Reverse Engineering - Recent Ad

- Page 238 and 239: 222 Reverse Engineering - Recent Ad

- Page 240 and 241: 224 Reverse Engineering - Recent Ad

- Page 242 and 243: 226 Reverse Engineering - Recent Ad

- Page 244 and 245: 228 Reverse Engineering - Recent Ad

- Page 246 and 247: 230 Reverse Engineering - Recent Ad

- Page 248 and 249: 232 Reverse Engineering - Recent Ad

- Page 250 and 251: 234 Reverse Engineering - Recent Ad

- Page 252 and 253: 236 Reverse Engineering - Recent Ad

- Page 254 and 255: 238 5. Summary and discussions Reve

- Page 256 and 257: 240 Reverse Engineering - Recent Ad

- Page 258 and 259: 242 Reverse Engineering - Recent Ad

- Page 260 and 261: 244 Reverse Engineering - Recent Ad

- Page 262 and 263: 246 Reverse Engineering - Recent Ad

- Page 264 and 265: 248 Reverse Engineering - Recent Ad

- Page 266 and 267: 250 Reverse Engineering - Recent Ad

- Page 268 and 269: 252 Reverse Engineering - Recent Ad

- Page 270 and 271: 254 Reverse Engineering - Recent Ad

- Page 272 and 273: 256 Reverse Engineering - Recent Ad

- Page 274 and 275: 258 Reverse Engineering - Recent Ad

- Page 276 and 277: 260 Reverse Engineering - Recent Ad

- Page 280 and 281: 264 Reverse Engineering - Recent Ad

- Page 282 and 283: 266 Reverse Engineering - Recent Ad

- Page 284 and 285: 268 Fig. 6. A closed polygon mesh r

- Page 286 and 287: 270 Reverse Engineering - Recent Ad

- Page 288 and 289: 272 3. Results Reverse Engineering

- Page 290 and 291: 274 Reverse Engineering - Recent Ad

- Page 292: 276 Reverse Engineering - Recent Ad