Installation Manual - Future Pipe Industries

Installation Manual - Future Pipe Industries

Installation Manual - Future Pipe Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1. Introduction<br />

This manual is written as a guide for supervisors and field engineers and explains the possibilities of Wavistrong<br />

systems. In addition this manual provides guidance on how to avoid and solve problems during installation.<br />

Reinforced thermosetting resin pipe (R.T.R.P.) systems offer, by their specific nature, many applications and<br />

advantages compared with other materials. In order to utilize all these properties it is essential, for those<br />

who use Wavistrong material, carefully to observe these guidelines.Please note that these instructions are for<br />

guidance only. Specifications written for a particular project will have priority.<br />

Although the procedures written in this manual are as complete as possible, it is not possible to describe all the<br />

different circumstances you may meet. For this reason our experienced supervisors may vary the described procedures<br />

in order to achieve an optimum solution, using the latest installation techniques and processing methods.<br />

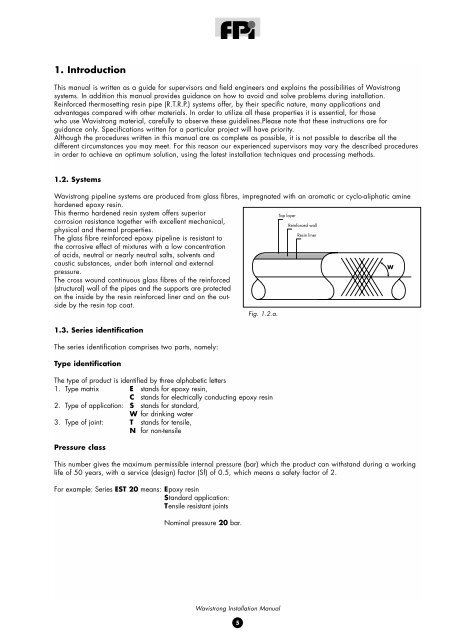

1.2. Systems<br />

Wavistrong pipeline systems are produced from glass fibres, impregnated with an aromatic or cyclo-aliphatic amine<br />

hardened epoxy resin.<br />

This thermo hardened resin system offers superior<br />

Top layer<br />

corrosion resistance together with excellent mechanical,<br />

Reinforced wall<br />

physical and thermal properties.<br />

Resin liner<br />

The glass fibre reinforced epoxy pipeline is resistant to<br />

the corrosive effect of mixtures with a low concentration<br />

of acids, neutral or nearly neutral salts, solvents and<br />

caustic substances, under both internal and external<br />

W<br />

pressure.<br />

The cross wound continuous glass fibres of the reinforced<br />

(structural) wall of the pipes and the supports are protected<br />

on the inside by the resin reinforced liner and on the outside<br />

by the resin top coat.<br />

Fig. 1.2.a.<br />

1.3. Series identification<br />

The series identification comprises two parts, namely:<br />

Type identification<br />

The type of product is identified by three alphabetic letters<br />

1. Type matrix E stands for epoxy resin,<br />

C stands for electrically conducting epoxy resin<br />

2. Type of application: S stands for standard,<br />

W for drinking water<br />

3. Type of joint: T stands for tensile,<br />

N for non-tensile<br />

Pressure class<br />

This number gives the maximum permissible internal pressure (bar) which the product can withstand during a working<br />

life of 50 years, with a service (design) factor (Sf) of 0.5, which means a safety factor of 2.<br />

For example: Series EST 20 means: Epoxy resin<br />

Standard application:<br />

Tensile resistant joints<br />

Nominal pressure 20 bar.<br />

Wavistrong <strong>Installation</strong> <strong>Manual</strong><br />

5