- Page 1 and 2:

GAIL (INDIA) LTD NEW DELHI GAIL (In

- Page 3 and 4:

ANNEXURE - I CONTRACTOR’S SCOPE O

- Page 5 and 6:

1.3 Any activity specifically not l

- Page 7 and 8:

converter, barriers, relays, cables

- Page 9 and 10:

standards etc. and obtaining all re

- Page 11 and 12:

c) Contractor shall prepare purchas

- Page 13 and 14:

) The gas custody transfer metering

- Page 15 and 16:

q) Platforms & cross over to be pro

- Page 17 and 18:

nn) Dual Isolation Valves shall be

- Page 19 and 20:

3.2.1 Design and terminology shall

- Page 21 and 22:

GAIL (INDIA) LTD NEW DELHI IEC-6033

- Page 23 and 24: Necessary filtration and double sta

- Page 25 and 26: 3.3.3.4 All instruments in the unit

- Page 27 and 28: 3.4.2.6 Junction boxes (as per the

- Page 29 and 30: Typical gas composition S.N PARAMET

- Page 31 and 32: � Pressure Class of Skid up to PR

- Page 33 and 34: esponsibility for delivering equipm

- Page 35 and 36: principal grain flow and notched pe

- Page 37 and 38: carried out at manufacturer’s wor

- Page 39 and 40: (e) Bubble wrapping as well as tran

- Page 41 and 42: Mandatory Spares: Shall be provided

- Page 43 and 44: application. Type approval certific

- Page 45 and 46: 16 Temperature gauges and Thermowel

- Page 47 and 48: 24 Standard specification for Inspe

- Page 49 and 50: GAIL (INDIA) LTD NEW DELHI JOB SPEC

- Page 51 and 52: 1.0 Introduction 1.1 General 1.2 Sc

- Page 53 and 54: ISO 170125: Calibration of all prim

- Page 55 and 56: separate limit switches for open an

- Page 57 and 58: measurement will not degrade by mor

- Page 59 and 60: computer for custody transfer flow

- Page 61 and 62: l) A statement of uncertainty for t

- Page 63 and 64: The flow computers shall be Micropr

- Page 65 and 66: KEYBOARD CAPABILITY: The data entry

- Page 67 and 68: Energy - Mcal/MMBTU/ MJ (user selec

- Page 69 and 70: LEL detectors/transmitters shall be

- Page 71 and 72: � The control panel shall also ha

- Page 73: GAIL (INDIA) LTD NEW DELHI ii) Anal

- Page 77 and 78: egulating the sample pressure & flo

- Page 79 and 80: III. Mole % CO2 IV. Mole % N2 Each

- Page 81 and 82: and ±0.5 % for components (mole%)

- Page 83 and 84: 9 Accessories Cell Battery and Char

- Page 85 and 86: S NO. TITLE 1 GENERAL CONTENTS 2 DE

- Page 87 and 88: 2.5 Standards 2.5.1 The instrumenta

- Page 89 and 90: 3.2.23 Supply of all types of consu

- Page 91 and 92: 4.3.1 Multitube/Multicore cables sh

- Page 93 and 94: 4.8.4 Cables shall have complete un

- Page 95 and 96: 4.12.1 All instruments shall be cal

- Page 97 and 98: ) Current generator (Instrument che

- Page 99 and 100: 7.0 MATERIALS SUPPLY 7.1 Materials

- Page 101 and 102: STANDARD SPECIFICATION FOR INSTRUME

- Page 103 and 104: 1 0 GENERAL 1.1 Scope 1.1.1 This st

- Page 105 and 106: per ASTM B 68M copper No. C 12200.

- Page 107 and 108: MAXIMUM WORKING PRESSURE AND HYDROS

- Page 109 and 110: NO. TITLE 1.0 GENERAL 2.0 DESIGN PH

- Page 111 and 112: d) List of deviations, if any, from

- Page 113 and 114: IS-3624 Specification for pressure

- Page 115 and 116: These drawings represent the nozzle

- Page 117 and 118: 2 DESIGN PHILOSOPHY 2.1 Instrumenta

- Page 119 and 120: approval from purchaser. c) In case

- Page 121 and 122: 2.14.1.6 Automatic sequential start

- Page 123 and 124: 2.21.1 Instrument junction boxes sh

- Page 125 and 126:

side. 2.24 Philosophy of Junction B

- Page 127 and 128:

) All relays and solenoid valves sh

- Page 129 and 130:

d) All receiver instruments shall b

- Page 131 and 132:

lamp test push button shall be used

- Page 133 and 134:

4.4.6 All hinges, screws and other

- Page 135 and 136:

The type of thermocouple shall be s

- Page 137 and 138:

operating value. c) Pressure switch

- Page 139 and 140:

level gauges shall have side mounte

- Page 141 and 142:

The integral flow assembly shall be

- Page 143 and 144:

of valve like butterfly, ball, rota

- Page 145 and 146:

drawings alongwith the timing calcu

- Page 147 and 148:

4.13.9 All accessories like positio

- Page 149 and 150:

4.16.1 Vibration and axial displace

- Page 151 and 152:

of 140 to 150 kg/cm2g while chargin

- Page 153 and 154:

eceiver at the camera side. The con

- Page 155 and 156:

7.3 If at any point of time during

- Page 157 and 158:

- rotary equipment running data etc

- Page 159 and 160:

individual alarm in DCS. 7.12.5 All

- Page 161 and 162:

7.14.25 Wiring colour code within t

- Page 163 and 164:

shall be routed to process or flare

- Page 165 and 166:

IP 55 and flame proof Ex˜d˜ suita

- Page 167 and 168:

Each components and the system shal

- Page 169 and 170:

f) All multi pair cables shall have

- Page 171 and 172:

) Monel or any other tubing shall b

- Page 173 and 174:

complete the job in all respect. 13

- Page 175 and 176:

provided. v) For impulse line with

- Page 177 and 178:

cables for insulation testing, ensu

- Page 179 and 180:

calibrate the instruments which sha

- Page 181 and 182:

LTD STANDARD SPECIFICATION FOR GAS

- Page 183 and 184:

LTD 1.1.1 This specification, toget

- Page 185 and 186:

LTD 2.2 Gas detection system shall

- Page 187 and 188:

LTD 2.10.8 Software features a) Dat

- Page 189 and 190:

LTD paint, colour as specified in J

- Page 191 and 192:

LTD 2.13.3.1 Alarm annunciator shal

- Page 193 and 194:

STANDARD SPECIFICATION FOR PRESSURE

- Page 195 and 196:

1.0 GENERAL 1.1 Scope 1.1.1 This sp

- Page 197 and 198:

a) Specification sheet for each gau

- Page 199 and 200:

d) Flange face shall be as per clau

- Page 201 and 202:

6.0 REJECTION 6.1 Vendor shall prep

- Page 203 and 204:

STANDARD SPECIFICATION FOR SELF ACT

- Page 205 and 206:

1.0 GENERAL 1.1 Scope 1.1.1 This st

- Page 207 and 208:

summing up all the deviations, from

- Page 209 and 210:

egulators shall have flanged end co

- Page 211 and 212:

2.6 Finish 2.6.1 The body shall be

- Page 213 and 214:

6.0 REJECTION 6.1 Vendor shall prep

- Page 215 and 216:

LTD S NO. TITLE 1 GENERAL CONTENTS

- Page 217 and 218:

LTD 1.1.3 In the event of any confl

- Page 219 and 220:

LTD d) Ring type joint flanges shal

- Page 221 and 222:

LTD 2.6.6 In general, an actuator o

- Page 223 and 224:

LTD Linearity and Hysterisis shall

- Page 225 and 226:

GAIL (INDIA) LTD NEW DELHI Abbrevia

- Page 227 and 228:

1.0 GENERAL 1.1 Scope 1.1.1 This sp

- Page 229 and 230:

) Minimum number of eight PVC / rub

- Page 231 and 232:

Smoke density rating not to exceed

- Page 233 and 234:

iii) Shrinkage test iv) Hot deforma

- Page 235 and 236:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 237 and 238:

CONTENTS 1.0 GENERAL 2.0 DESIGN AND

- Page 239 and 240:

1.1.3 In the event of any conflict

- Page 241 and 242:

the terminal block for terminating

- Page 243 and 244:

3.2.1 The following information sha

- Page 245 and 246:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 247 and 248:

CONTENTS 1.0 GENERAL 2.0 DESIGNS AN

- Page 249 and 250:

specifically indicated, the specifi

- Page 251 and 252:

sheet, the number of terminals for

- Page 253 and 254:

4.3.2 In the event when witness ins

- Page 255 and 256:

1 GENERAL CONTENTS 2 DESIGN AND CON

- Page 257 and 258:

attached along with the material re

- Page 259 and 260:

4.2 review: fittings. Vendor shall

- Page 261 and 262:

GAIL (INDIA) LTD NEW DELHI HYDROSTA

- Page 263 and 264:

1.0 GENERAL 2.0 DESIGN AND CONSTRUC

- Page 265 and 266:

IS-2148 Electrical Apparatus for Ex

- Page 267 and 268:

1.3 Drawing and Data 1.3.1 Detailed

- Page 269 and 270:

1 Instruments Bottom Row Middle Row

- Page 271 and 272:

a) 50 mm minimum space shall be pro

- Page 273 and 274:

4.1 Unless otherwise specified, pur

- Page 275 and 276:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 277 and 278:

1.0 GENERAL 2.0 DESIGN AND CONSTRUC

- Page 279 and 280:

detailed technical offer is require

- Page 281 and 282:

double block and bleed for the bypa

- Page 283 and 284:

Annexure-1 of this specification. D

- Page 285 and 286:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 287 and 288:

1.1 Scope 1.1.1 This specification,

- Page 289 and 290:

proto-type design or items not meet

- Page 291 and 292:

2.3.1 Body 2.3.1.1 Unless otherwise

- Page 293 and 294:

connections shall be blinded / plug

- Page 295 and 296:

) Hydrostatic test as per clause 4.

- Page 297 and 298:

GAIL (INDIA) LTD NEW DELHI Abbrevia

- Page 299 and 300:

1.0 General 1.1 Scope 1.1.2 This sp

- Page 301 and 302:

manufactured outside India. e) Devi

- Page 303 and 304:

Weatherproof housing IP-65 to IEC-6

- Page 305 and 306:

alarm is provided as diagnostic mai

- Page 307 and 308:

extra functionality and/or software

- Page 309 and 310:

) Reading coefficient, if any c) Pe

- Page 311 and 312:

6.0 REJECTION 6.1 Vendor shall prep

- Page 313 and 314:

Annexure 2 GASKETS MATERIAL REQUIRE

- Page 315 and 316:

1.0 GENERAL GAIL (INDIA) LTD NEW DE

- Page 317 and 318:

esponsibility shall include the fol

- Page 319 and 320:

2.1.1 Temperature gauges shall be o

- Page 321 and 322:

) Flanged end connections shall be

- Page 323 and 324:

f) Review of all certificates and t

- Page 325 and 326:

LTD SECTION 1.0 GENERAL TABLE of CO

- Page 327 and 328:

LTD without any commercial implicat

- Page 329 and 330:

LTD IEC 60079 Electrical Apparatus

- Page 331 and 332:

LTD Direction of flow 4.9 Field act

- Page 333 and 334:

LTD meters for the given process co

- Page 335 and 336:

LTD Uncorrected and corrected forwa

- Page 337 and 338:

LTD 9.1.1 PURCHASER may visit the p

- Page 339 and 340:

LTD 9.4.1 Site Acceptance shall con

- Page 341 and 342:

STANDARD SPECIFICATION FOR GAS CHRO

- Page 343 and 344:

1.0 SCOPE 9.1 This specification co

- Page 345 and 346:

H2S < ppm by weight S < ppm by weig

- Page 347 and 348:

5.2 After placement of purchase ord

- Page 349 and 350:

Gas Gr. IIA & IIB Temp T3. All anal

- Page 351 and 352:

classification indicated in the pur

- Page 353 and 354:

6.4.13 The programmer will be certi

- Page 355 and 356:

c) Temperature, pressure and flow r

- Page 357 and 358:

10.2 The approved spare parts and c

- Page 359 and 360:

CONTENTS 1.0 SCOPE 2.0 DEFINITIONS

- Page 361 and 362:

AGA Report No 3 Orifice Metering of

- Page 363 and 364:

5.2.2 Analog inputs shall be 4-20 m

- Page 365 and 366:

5.8.4 The minimum protocol supporte

- Page 367 and 368:

such a way that the flow controller

- Page 369 and 370:

6.3 GAS TURBINE METER CALCULATIONS

- Page 371 and 372:

7.0 DATA MANAGEMENT AND USER INTERF

- Page 373 and 374:

♦ Daily total of the standard vol

- Page 375 and 376:

♦ Hourly averages of differential

- Page 377 and 378:

♦ Calibrated Static Pressure Rang

- Page 379 and 380:

Analog input Analog output 8.3.3 A

- Page 381 and 382:

9.3.1 PURCHASER shall not be invite

- Page 383 and 384:

VENDOR shall provide a schedule det

- Page 385 and 386:

minimum the following topics shall

- Page 387 and 388:

GAIL (INDIA) LTD NEW DELHI THERMOCO

- Page 389 and 390:

GAIL (INDIA) LTD NEW DELHI THERMOWE

- Page 391 and 392:

GAIL (INDIA) LTD NEW DELHI THERMOWE

- Page 393 and 394:

GAIL (INDIA) LTD NEW DELHI INSTRUME

- Page 395 and 396:

GAIL (INDIA) LTD NEW DELHI INSTRUME

- Page 397 and 398:

GAIL (INDIA) LTD NEW DELHI SUPPORT

- Page 399 and 400:

GAIL (INDIA) LTD NEW DELHI CANOPY F

- Page 401 and 402:

GAIL (INDIA) LTD NEW DELHI TRAY SUP

- Page 403 and 404:

GAIL (INDIA) LTD NEW DELHI INSTRUME

- Page 405 and 406:

GAIL (INDIA) LTD NEW DELHI INSTRUME

- Page 407 and 408:

TUBING HOOK-UP WITH CONTROL VALVE A

- Page 409 and 410:

GAIL (INDIA) LTD NEW DELHI PRESSURE

- Page 411 and 412:

GAIL (INDIA) LTD NEW DELHI PRESSURE

- Page 413 and 414:

GAIL (INDIA) LTD NEW DELHI DP INSTR

- Page 415 and 416:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 417 and 418:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 419 and 420:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 421 and 422:

GAIL (INDIA) LTD NEW DELHI DIMESION

- Page 423 and 424:

1.0 SCOPE 2.0 REFERENCE DOCUMENTS 3

- Page 425 and 426:

In case of conflict between the req

- Page 427 and 428:

GAIL (INDIA) LTD NEW DELHI movement

- Page 429 and 430:

4.25 All mounting accessories neede

- Page 431 and 432:

8.1 All threaded and flanged openin

- Page 433 and 434:

1. Stop Valve (3/4” NPT), 2. Chec

- Page 435 and 436:

SL. NO GAIL (INDIA) LTD NEW DELHI G

- Page 437 and 438:

1.0 SCOPE GAIL (INDIA) LTD NEW DELH

- Page 439 and 440:

ASTM A-370 - Standard Test Methods

- Page 441 and 442:

4.2 Valve body design shall be eith

- Page 443 and 444:

) Flanged end, if specified, shall

- Page 445 and 446:

d) Direction of operation of hand w

- Page 447 and 448:

5.1.7 a) All finished wrought weld

- Page 449 and 450:

) Test certificates of hydrostatic

- Page 451 and 452:

k) List of recommended spares requi

- Page 453 and 454:

STANDARD SPECIFICATION FOR PIPELINE

- Page 455 and 456:

1.0 SCOPE This Specification covers

- Page 457 and 458:

3.5 For all such valves where Carbo

- Page 459 and 460:

4.12 Valves shall be suitable for e

- Page 461 and 462:

) Body castings of valves shall be

- Page 463 and 464:

d) Test report on operation of valv

- Page 465 and 466:

c) Fabrication details of all valve

- Page 467 and 468:

GAIL (INDIA) LTD NEW DELHI STANDARD

- Page 469 and 470:

1.0 SCOPE This specification covers

- Page 471 and 472:

4.9 All welds shall be made by weld

- Page 473 and 474:

other suitable material. All valves

- Page 475 and 476:

STANDARD SPECIFICATION FOR SEAMLESS

- Page 477 and 478:

1.0 SCOPE This specification covers

- Page 479 and 480:

e used for other hydrocarbon servic

- Page 481 and 482:

9.0 DOCUMENTATION 9.1 Prior to ship

- Page 483 and 484:

1.0 SCOPE 2.0 REFERENCE DOCUMENTS 3

- Page 485 and 486:

MSS-SP-97 - Forged Carbon Steel Bra

- Page 487 and 488:

maintained. Repair welding procedur

- Page 489 and 490:

SPECIFICATION FOR QUICK OPENING END

- Page 491 and 492:

SCOPE This specification covers the

- Page 493 and 494:

4.6 End closure shall be provided w

- Page 495 and 496:

7.3 Before shipment, closures shall

- Page 497 and 498:

WELDING SPECIFICATION FOR FABRICATI

- Page 499 and 500:

(This specification shall be used i

- Page 501 and 502:

4.8 Tungsten electrodes used shall

- Page 503 and 504:

8.2 Cleaning (a) The ends to be wel

- Page 505 and 506:

GAIL (INDIA) LTD NEW DELHI Metal st

- Page 507 and 508:

(h) Manufacturer's test certificate

- Page 509 and 510:

Inspection of all welds shall be ca

- Page 511 and 512:

(a) Whenever such tests are specifi

- Page 513 and 514:

ELECTRODE QUALIFICATION TEST RECORD

- Page 515 and 516:

Macro Test Results : Fracture Test

- Page 517 and 518:

Soaking Time (Hrs.) _______________

- Page 519 and 520:

FILLER METALS GAIL (INDIA) LTD NEW

- Page 521 and 522:

GAIL (INDIA) LTD NEW DELHI EXHIBIT

- Page 523 and 524:

OTHER TESTS Type of Test __________

- Page 525 and 526:

Guided Bend Test Results Type of Fi

- Page 527 and 528:

1. Name: 2. Identification: 3. Date

- Page 529 and 530:

TECHNICAL NOTES FOR PIPES GAIL (IND

- Page 531 and 532:

GAIL (INDIA) LTD NEW DELHI Material

- Page 533 and 534:

Temp ( o F) Material A335 Gr. P 11

- Page 535 and 536:

3.0 HYDROSTATIC TEST 3.1 All pipes

- Page 537 and 538:

c) Stainless Steel E.FS.W (8” and

- Page 539 and 540:

S. NO. TITLE 1.0 GENERAL 2.0 DOCUME

- Page 541 and 542:

2.2.2 Test report shall be supplied

- Page 543 and 544:

GAIL (INDIA) LTD NEW DELHI ANSI 600

- Page 545 and 546:

3.18.5 The face-to-face dimensions

- Page 547 and 548:

4.3 Where gear operator is not call

- Page 549 and 550:

casting to be radiographed for type

- Page 551 and 552:

GAIL (INDIA) LTD NEW DELHI BYPASS P

- Page 553 and 554:

GAIL (INDIA) LTD NEW DELHI rating a

- Page 555 and 556:

GAIL (INDIA) LTD NEW DELHI TECHNICA

- Page 557 and 558:

1.7.4 All welded fittings shall be

- Page 559 and 560:

1.20 Swage nipples (concentric/ecce

- Page 561 and 562:

3.9 Each size of fitting shall be s

- Page 563 and 564:

1.0 GENERAL 1.1 All items, their di

- Page 565 and 566:

1.16 AWWA C207 flanges shall be hub

- Page 567 and 568:

GAIL (INDIA) LTD NEW DELHI TECHNICA

- Page 569 and 570:

GAIL (INDIA) LTD NEW DELHI TECHNICA

- Page 571 and 572:

GAIL (INDIA) LTD NEW DELHI TECHNICA

- Page 573 and 574:

a. Sizes 26” and above b. Class 9

- Page 575 and 576:

Abbreviations: PMI : Positive Mater

- Page 577 and 578:

1.0 SCOPE This specification covers

- Page 579 and 580:

2.13 Providing insert plates from c

- Page 581 and 582:

have been fabricated I erected. Mat

- Page 583 and 584:

Reinforcement pads shall be provide

- Page 585 and 586:

specification or isometric or line

- Page 587 and 588:

c. Hydrostatic Testing of the syste

- Page 589 and 590:

No pipe shoe I cradle shall be offs

- Page 591 and 592:

Abbreviation :- DP/LP: Dye Liquid P

- Page 593 and 594:

1. GENERAL 1.1 SCOPE The specificat

- Page 595 and 596:

12 Bead Deflection 2.5 mm or less 1

- Page 597 and 598:

4. TABLE-I (with applicable Notes)

- Page 599 and 600:

IN SP N. CL AS S III TABLE 1 : CLAS

- Page 601 and 602:

4. Magnetic particle & the Liquid p

- Page 603 and 604:

7. Hardness Test: GAIL (INDIA) LTD

- Page 605 and 606:

c) Piping less than 38 mm (1.5”)

- Page 607 and 608:

Sl. No. Description 1. SCOPE 2. INS

- Page 609 and 610:

1.0 SCOPE This specification covers

- Page 611 and 612:

Pumps, compressors and other rotary

- Page 613 and 614:

supports shall be removed only afte

- Page 615 and 616:

When testing with air, pressure sha

- Page 617 and 618:

GAIL (INDIA) LTD NEW DELHI CONTENTS

- Page 619 and 620:

1.0 GENERAL 1.1 These technical spe

- Page 621 and 622:

IS-5 : Colour coding IS-101 : Metho

- Page 623 and 624:

period, at his sole discretion and

- Page 625 and 626:

The compatibility of finishing coat

- Page 627 and 628:

k. If spray gun shows choking, imme

- Page 629 and 630:

5.10.1 Shop priming / pre-erection

- Page 631 and 632:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 633 and 634:

6.0 PAINT MATERIALS Paint manufactu

- Page 635 and 636:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 637 and 638:

F-14: Specially formulated polyamin

- Page 639 and 640:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 641 and 642:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 643 and 644:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 645 and 646:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 647 and 648:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 649 and 650:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 651 and 652:

18.2 The colour code scheme is inte

- Page 653 and 654:

19.0 IDENTIFICATION OF VESSELS, PIP

- Page 655 and 656:

pinhole detector and positector whe

- Page 657 and 658:

DENSITY - D 1475 DIPPING PROPERIES

- Page 659 and 660:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 661 and 662:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 663 and 664:

GAIL (INDIA) LTD NEW DELHI DOCUMENT

- Page 665 and 666:

STANDARD SPECIFICATION FOR POSITIVE

- Page 667 and 668:

1.0 SCOPE This specification applie

- Page 669 and 670:

5.2 Instrument or methods used for

- Page 671 and 672:

GAIL (INDIA) LTD NEW DELHI POSITIVE

- Page 673 and 674:

GAIL (INDIA) LTD NEW DELHI CONTENTS

- Page 675 and 676:

3.0 SCOPE OF SERVICES 4.0 DESIGN (i

- Page 677 and 678:

5.10 All nozzles above 3" NB size s

- Page 679 and 680:

(a) Ultrasonic Examinations GAIL (I

- Page 681 and 682:

(iv) All Environment (temp. 80-400

- Page 683 and 684:

11.11 Manufacturer related informat

- Page 685 and 686:

GAIL (India) Limited New Delhi CONT

- Page 687 and 688:

4.0 CLASS DESIGNATION CODE The pipi

- Page 689 and 690:

10.4 For RTJ flanges, octagonal rin

- Page 691 and 692:

Sl. No. 1 2 Pipeline Specialty item

- Page 693 and 694:

GAIL (India) Limited New Delhi ANNE

- Page 695 and 696:

BRANCH PIPE (SIZE IN INCHES) GAIL (

- Page 697 and 698:

FLNG.FIG8 02.000 08.000 B-16.48 AST

- Page 699 and 700:

GAIL (India) Limited New Delhi ANNE

- Page 701 and 702:

BRANCH PIPE (SIZE IN INCHES) GAIL (

- Page 703 and 704:

T.EQUAL 02.00 06.00 STD B 16.11 AST

- Page 705 and 706:

GAIL (India) Limited New Delhi ANNE

- Page 707 and 708:

BRANCH PIPE (SIZE IN INCHES) (B1A)

- Page 709 and 710:

FLNG.FIG8 02.000 08.000 B-16.48 AST

- Page 711 and 712:

GAIL (India) Limited New Delhi PIPI

- Page 713 and 714:

PIPING CLASS : D1A, 600 # BASE MATE

- Page 715 and 716:

BRANCH PIPE (SIZE IN INCHES) 72 72

- Page 717 and 718:

FLNG.BLIND 00.500 01.500 B-16.5 AST

- Page 719 and 720:

VLV.BALL 02.000 24.000 API-6D BODY-

- Page 721 and 722:

PIPING CLASS : A4A, 150 # BASE MATE

- Page 723 and 724:

CODE DESCRIPTION F SADDLE FUSED JT

- Page 725 and 726:

Gasket Group (A4A) GASKET 00.500 14

- Page 727 and 728:

PIPING CLASS : B4A, 300 # BASE MATE

- Page 729 and 730:

CODE DESCRIPTION F SADDLE FUSED JT

- Page 731 and 732:

VLV.GLOBE 02.000 12.000 BS- 1873 VL

- Page 733 and 734:

PIPING CLASS : D4A, 600 # BASE MATE

- Page 735 and 736:

CODE DESCRIPTION F SADDLE FUSED JT

- Page 737 and 738:

CPLNG.RED 01.000 01.500 B-16.11 AST

- Page 739 and 740:

PIPING CLASS : J2A, 150 # BASE MATE

- Page 741 and 742:

CODE DESCRIPTION F SADDLE FUSED JT

- Page 745 and 746:

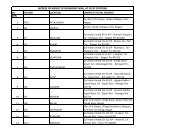

CAPACITY AUGMENTATION OF AJPL (Ph-1

- Page 747 and 748:

Contractor Client GAIL INDIA LTD ,N

- Page 749 and 750:

Contractor Client GAIL INDIA LTD ,N

- Page 751 and 752:

Sl. No Item Contractor Client GAIL

- Page 753 and 754:

CONTRACTOR’S SCOPE OF SUPPLY AND

- Page 755 and 756:

NOTE: 1. INSTALLATION SUPERVISION &

- Page 757 and 758:

1.0 BIDDER DRAWING/DOCUMENT REQUIRE

- Page 759 and 760:

(including foundation details, 16 w

- Page 761 and 762:

GAIL (INDIA) LTD NEW DELHI TECHNICA

- Page 763 and 764:

Sl. No. Description Bidder’s Resp

- Page 765 and 766:

Sl. No. Description Bidder’s Resp

- Page 767 and 768:

VENDOR LIST The materials required

- Page 769 and 770:

1) Forain S.R.L. 2) GD Engineering

- Page 771 and 772:

18) M/s Sakhi Engineers Pvt. Ltd. 1

- Page 773 and 774:

7) M/s CMI Limited 8) M/s - Cords C

- Page 775 and 776:

4) Goodluck Steel Tubes Ltd, India

- Page 777 and 778:

5) Chemtrols Engineering Ltd, India

- Page 779 and 780:

8) Nagman Sensors Pvt Ltd 9) Tecnom

- Page 781 and 782:

incomplete and incorrect Checklist

- Page 783 and 784:

PERFORMANCE GUARANTEE CERTIFICATE (

- Page 785 and 786:

EQUIPMENT QUALIFICATION CRITERION (

- Page 787 and 788:

Company symbol(insert FACTORY ACCEP

- Page 789 and 790:

1. PREFACE 1.1 Introduction: This d

- Page 791 and 792:

2. VISUAL INSPECTION OF SKID. 2.1 S

- Page 793 and 794:

1. Check the functional test as per

- Page 795 and 796:

Any discrepancy observed during FAT

- Page 797 and 798:

Company symbol(insert TEST CERTIFIC

- Page 799 and 800:

Company symbol(insert TEST CERTIFIC

- Page 801 and 802:

Company symbol(insert FAT CHECK LIS

- Page 803 and 804:

Company symbol(insert FAT CHECK LIS

- Page 805 and 806:

Company symbol(insert TEST CERTIFIC

- Page 807 and 808:

Company symbol(insert FAT CHECK LIS

- Page 809 and 810:

Company symbol(insert FAT CHECK LIS

- Page 811 and 812:

Company symbol(insert FAT CHECK LIS

- Page 813 and 814:

_____________________ _____________

- Page 815 and 816:

Standard Register List in Flow comp

- Page 817 and 818:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 819 and 820:

1. This Valve Data Sheet shall be r

- Page 821 and 822:

GAIL (INDIA) LTD NEW DELHI CONTROL

- Page 823 and 824:

DATA SHEETS DIFFERENTIAL PRESSURE I

- Page 825 and 826:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 827 and 828:

“ * “ By Vendor, “**”-From

- Page 829 and 830:

UNITS : Gas Flow - MMSCMD, Liquid F

- Page 831 and 832:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 833 and 834:

Notes ** Refer Process data mention

- Page 835 and 836:

PRESSURE GAUGES (TYPICAL) UNITS: Fl

- Page 837 and 838:

GAIL (INDIA) LTD NEW DELHI PRESSURE

- Page 839 and 840:

GAIL (INDIA) LTD NEW DELHI Receiver

- Page 841 and 842:

Receiver INDICATOR Instruments (Typ

- Page 843 and 844:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 845 and 846:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 847 and 848:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 849 and 850:

DATA SHEETS TEMPERATURE TRANSMITTER

- Page 851 and 852:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 853 and 854:

NOTES: * TO BE FURNISHED BY VENDOR

- Page 855 and 856:

GAIL (INDIA) LTD NEW DELHI INTRINSI

- Page 857 and 858:

DATA SHEETS LEL DETECTOTS/ TRANSMIT

- Page 859 and 860:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 861 and 862:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 863 and 864:

GAIL (INDIA) LTD NEW DELHI BALL VAL

- Page 865 and 866:

GAIL (INDIA) LTD NEW DELHI GLOBE VA

- Page 867 and 868:

GAIL (INDIA) LTD NEW DELHI DATA SHE

- Page 869:

GAIL (INDIA) LTD NEW DELHI PLUG VAL