Mechanics and Tribology of MEMS Materials - prod.sandia.gov ...

Mechanics and Tribology of MEMS Materials - prod.sandia.gov ...

Mechanics and Tribology of MEMS Materials - prod.sandia.gov ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2 Strength Distributions in SUMMiT TM SMM Polysilicon<br />

2.1 Weibull Analysis <strong>of</strong> Strength Distributions in SUMMiT TM Polysilicon<br />

Monotonic, time-independent failure in brittle materials is typically driven by preexisting<br />

processing-induced flaws. In such a case, there is a statistical distribution <strong>of</strong> flaw sizes<br />

within the material, which results in a distribution in failure strengths. Such strength variability<br />

in brittle materials can <strong>of</strong>ten be described by the Weibull distribution. The two-parameter<br />

Weibull distribution can be expressed by the following probability density function (PDF):<br />

⎡ ⎛ σ ⎞<br />

P = 1−<br />

exp⎢−<br />

⎜<br />

⎟<br />

⎢⎣<br />

⎝σ<br />

θ ⎠<br />

where P represents the probability <strong>of</strong> failure, σ represents the applied stress, σθ, is the scale<br />

parameter <strong>of</strong>ten called the characteristic strength, <strong>and</strong> m is the shape parameter <strong>of</strong>ten called the<br />

Weibull modulus. By taking the natural logarithm <strong>of</strong> both sides <strong>of</strong> the previous equation twice, a<br />

linear relationship is established which can be used to evaluate data graphically:<br />

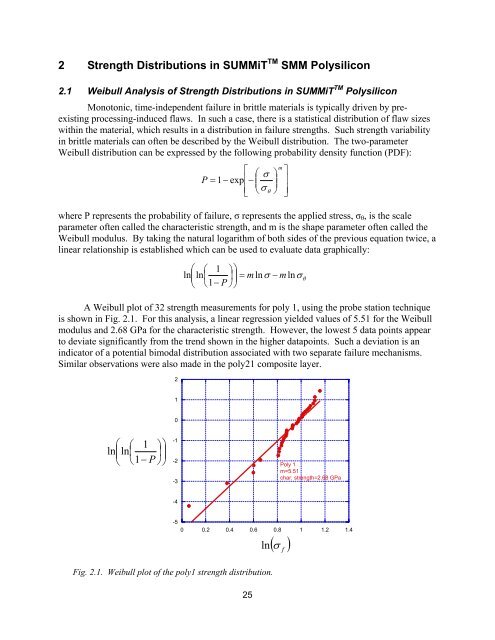

A Weibull plot <strong>of</strong> 32 strength measurements for poly 1, using the probe station technique<br />

is shown in Fig. 2.1. For this analysis, a linear regression yielded values <strong>of</strong> 5.51 for the Weibull<br />

modulus <strong>and</strong> 2.68 GPa for the characteristic strength. However, the lowest 5 data points appear<br />

to deviate significantly from the trend shown in the higher datapoints. Such a deviation is an<br />

indicator <strong>of</strong> a potential bimodal distribution associated with two separate failure mechanisms.<br />

Similar observations were also made in the poly21 composite layer.<br />

⎛ ⎛ 1 ⎞⎞<br />

ln⎜ln⎜<br />

⎟⎟<br />

⎝ ⎝1<br />

− P ⎠⎠<br />

Fig. 2.1. Weibull plot <strong>of</strong> the poly1 strength distribution.<br />

2<br />

1<br />

0<br />

-1<br />

-2<br />

-3<br />

-4<br />

25<br />

m<br />

⎤<br />

⎥<br />

⎥⎦<br />

⎛ ⎛ 1 ⎞⎞<br />

ln⎜ln⎜ ⎟⎟<br />

= mlnσ<br />

− mln<br />

⎝ ⎝1−<br />

P ⎠⎠<br />

ln(<br />

σ f )<br />

σθ<br />

Poly 1<br />

m=5.51<br />

char. strength=2.68 GPa<br />

-5<br />

0 0.2 0.4 0.6 0.8 1 1.2 1.4