ppc riebeeck mine and cement factory - Aurecon AME ...

ppc riebeeck mine and cement factory - Aurecon AME ...

ppc riebeeck mine and cement factory - Aurecon AME ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PPC Riebeeck West: Storm water Management Plan Page 17<br />

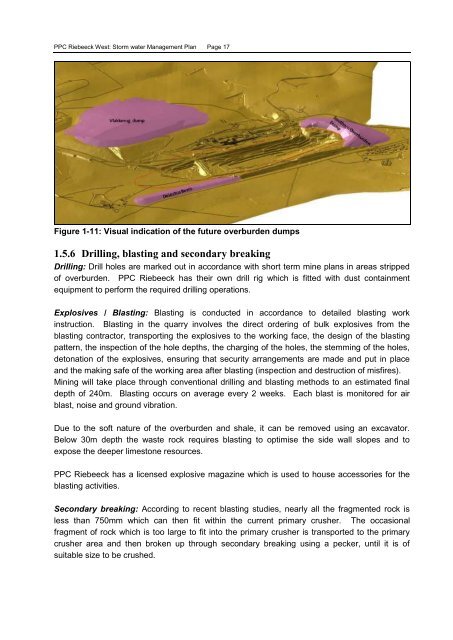

Figure 1-11: Visual indication of the future overburden dumps<br />

1.5.6 Drilling, blasting <strong>and</strong> secondary breaking<br />

Drilling: Drill holes are marked out in accordance with short term <strong>mine</strong> plans in areas stripped<br />

of overburden. PPC Riebeeck has their own drill rig which is fitted with dust containment<br />

equipment to perform the required drilling operations.<br />

Explosives / Blasting: Blasting is conducted in accordance to detailed blasting work<br />

instruction. Blasting in the quarry involves the direct ordering of bulk explosives from the<br />

blasting contractor, transporting the explosives to the working face, the design of the blasting<br />

pattern, the inspection of the hole depths, the charging of the holes, the stemming of the holes,<br />

detonation of the explosives, ensuring that security arrangements are made <strong>and</strong> put in place<br />

<strong>and</strong> the making safe of the working area after blasting (inspection <strong>and</strong> destruction of misfires).<br />

Mining will take place through conventional drilling <strong>and</strong> blasting methods to an estimated final<br />

depth of 240m. Blasting occurs on average every 2 weeks. Each blast is monitored for air<br />

blast, noise <strong>and</strong> ground vibration.<br />

Due to the soft nature of the overburden <strong>and</strong> shale, it can be removed using an excavator.<br />

Below 30m depth the waste rock requires blasting to optimise the side wall slopes <strong>and</strong> to<br />

expose the deeper limestone resources.<br />

PPC Riebeeck has a licensed explosive magazine which is used to house accessories for the<br />

blasting activities.<br />

Secondary breaking: According to recent blasting studies, nearly all the fragmented rock is<br />

less than 750mm which can then fit within the current primary crusher. The occasional<br />

fragment of rock which is too large to fit into the primary crusher is transported to the primary<br />

crusher area <strong>and</strong> then broken up through secondary breaking using a pecker, until it is of<br />

suitable size to be crushed.

![CRR IV FEIR ~ 26042010 [FINAL].pdf - Environmental Projects](https://img.yumpu.com/21973020/1/184x260/crr-iv-feir-26042010-finalpdf-environmental-projects.jpg?quality=85)