ppc riebeeck mine and cement factory - Aurecon AME ...

ppc riebeeck mine and cement factory - Aurecon AME ...

ppc riebeeck mine and cement factory - Aurecon AME ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PPC Riebeeck West: Storm water Management Plan Page 25<br />

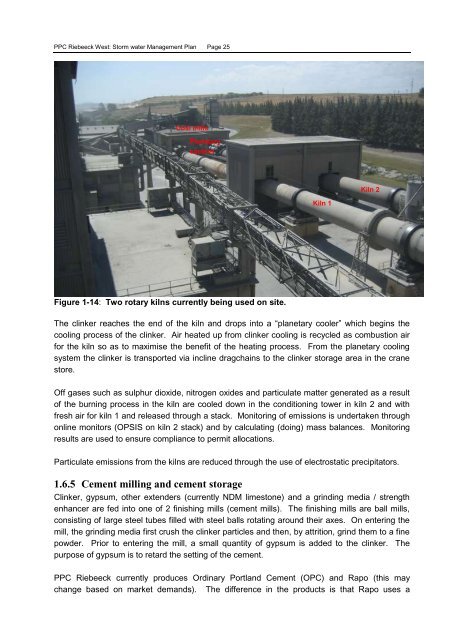

Coal mills<br />

Planetary<br />

coolers<br />

Figure 1-14: Two rotary kilns currently being used on site.<br />

Kiln 1<br />

Kiln 2<br />

The clinker reaches the end of the kiln <strong>and</strong> drops into a “planetary cooler” which begins the<br />

cooling process of the clinker. Air heated up from clinker cooling is recycled as combustion air<br />

for the kiln so as to maximise the benefit of the heating process. From the planetary cooling<br />

system the clinker is transported via incline dragchains to the clinker storage area in the crane<br />

store.<br />

Off gases such as sulphur dioxide, nitrogen oxides <strong>and</strong> particulate matter generated as a result<br />

of the burning process in the kiln are cooled down in the conditioning tower in kiln 2 <strong>and</strong> with<br />

fresh air for kiln 1 <strong>and</strong> released through a stack. Monitoring of emissions is undertaken through<br />

online monitors (OPSIS on kiln 2 stack) <strong>and</strong> by calculating (doing) mass balances. Monitoring<br />

results are used to ensure compliance to permit allocations.<br />

Particulate emissions from the kilns are reduced through the use of electrostatic precipitators.<br />

1.6.5 Cement milling <strong>and</strong> <strong>cement</strong> storage<br />

Clinker, gypsum, other extenders (currently NDM limestone) <strong>and</strong> a grinding media / strength<br />

enhancer are fed into one of 2 finishing mills (<strong>cement</strong> mills). The finishing mills are ball mills,<br />

consisting of large steel tubes filled with steel balls rotating around their axes. On entering the<br />

mill, the grinding media first crush the clinker particles <strong>and</strong> then, by attrition, grind them to a fine<br />

powder. Prior to entering the mill, a small quantity of gypsum is added to the clinker. The<br />

purpose of gypsum is to retard the setting of the <strong>cement</strong>.<br />

PPC Riebeeck currently produces Ordinary Portl<strong>and</strong> Cement (OPC) <strong>and</strong> Rapo (this may<br />

change based on market dem<strong>and</strong>s). The difference in the products is that Rapo uses a

![CRR IV FEIR ~ 26042010 [FINAL].pdf - Environmental Projects](https://img.yumpu.com/21973020/1/184x260/crr-iv-feir-26042010-finalpdf-environmental-projects.jpg?quality=85)