EIA-REP-325d-12 _BB_ - 201.09.14.pdf - SAHRA

EIA-REP-325d-12 _BB_ - 201.09.14.pdf - SAHRA

EIA-REP-325d-12 _BB_ - 201.09.14.pdf - SAHRA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

having the least detrimental environmental impacts on the surrounding environment as rehabilitation is<br />

continuous with mining operations.<br />

In terms of this project various mining methods alternatives were investigated and are discussed below.<br />

11.6.1 Area Mining<br />

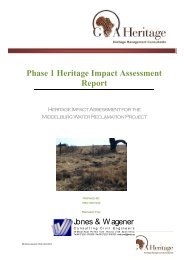

The most used surface mining method for coal is strip or area mining (Refer to Figure <strong>12</strong>: : An example of an open<br />

cast mine depicting the visual impact impact). ). Strip mining exposes the coal by removing the overburden (t (the earth<br />

above the coal seam(s)) in long cuts or strips. The spoil from the first strip is deposited in an area outside the<br />

planned mining area. Spoil from subsequent cuts is deposited as fill in the previous cut after coal has been<br />

removed. Usually, the process rocess is to drill the strip of overburden next to the previously mined strip. The drill holes<br />

are filled with explosives and blasted. The overburden is then removed using large eart earthmoving hmoving equipment such<br />

as draglines, shovel, excavator and trucks, or bucket-wheels and conveyors. This overburden is put into the<br />

previously mined (and now empty) strip.<br />

When all the overburden is removed removed, , the underlying coal seam is exposed as a 'block' of coal. This block of coal<br />

may be drilled and blasted (if hard) or otherwise loaded onto trucks or conveyors for transport to the coal<br />

preparation (or wash) plant. Once this strip is empty of coal, the pr process ocess is repeated with a new strip being<br />

created next to it. This method is most suitable for areas with flat terrain.<br />

The suitability of equipment is governed by geologic conditions. For example, to remove overburden that is loose<br />

or unconsolidated, a bucket wheel excavator might be most productive. The life of some area mines may be<br />

more than 50 years.<br />

Figure <strong>12</strong>: : An example of an open cast mine depicting the visual impact<br />

<strong>EIA</strong>-<strong>REP</strong>-<strong>325d</strong>-11<br />

October 20<strong>12</strong><br />

111