Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

202 |<br />

GRANULE POTWASHER METOS WD-80GR<br />

■ Large capacity: five GN 1/1 containers, max 60 GN1/1 per hour<br />

■ Diagnostics facilitates HACCP<br />

■ Superior drying with spinning<br />

■ Granule separation with double-pump technology saves money<br />

■ The area in front of the machine is kept free of dirt and granules<br />

Granule washing machines clean dishes with water<br />

containing p<strong>la</strong>stic granules. Even burnt on dirt is<br />

removed quickly and easily. The dishes don’t need<br />

to be soaked before granule washing, only loose residue is<br />

scraped off to avoid unnecessary soiling of the wash water.<br />

Large capacity in a small space<br />

The dishes can be loaded directly onto the rack pulled out on the<br />

door or two trolleys and two racks can be used to reach maximum<br />

capacity. For scraping of the dishes the prewash table can be used.<br />

Ingenious washing programmes<br />

The machine has three washing programmes, two with granules and<br />

one with water only. The same programmes can also be selected<br />

without spinning when washing utensils and dishes that are difficult<br />

to fix in the rack.<br />

When the machine starts, the wash rack starts to rotate and the<br />

programme starts with granule wash. The programmable granule<br />

washing time has been set at the factory to 3 minutes for the short<br />

and 6 minutes for the long cycle. The granule wash is followed by a<br />

pump rinse cycle, the duration of which can also be programmed.<br />

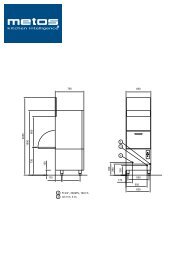

The <strong>la</strong>rge picture shows the <strong>Metos</strong><br />

WD-80GR HC with two racks, two<br />

trolleys and the granule dishwasher<br />

included in the delivery. The use of two<br />

racks and two trolleys provides<br />

maximum capacity.<br />

When working with a single rack the<br />

dishes are p<strong>la</strong>ced in the rack on the<br />

door (small picture).<br />

Before the final rinse the dishes are spun at great speed, at which<br />

point the spinning speed removes the granules and the wash water<br />

from the dishes. The final rinse is followed by a final spinning with<br />

an increased rotation speed, producing a better drying result with a<br />

smaller amount of rinse aid. After the final spinning an efficient<br />

condensing unit removes the steam from the machine.<br />

Top-notch hygiene and ease of operation<br />

Electronic control monitors the rinse and washing temperature,<br />

warns of too low temperatures and secures the rinse water amount.<br />

The machine also secures the purity of the wash water. These features<br />

make HACCP easier. The machine also indicates if the overflow<br />

pipe is out of p<strong>la</strong>ce or the tap is closed.<br />

Removal of the granules from the machine is easy. A collection box<br />

is p<strong>la</strong>ced in lieu of the tank strainer. The granules are driven into<br />

the box by the wash program. In the collection box the granules<br />

can be rinsed under a shower. Checking the granule level is easy:<br />

the right granule level is clearly marked on the collection box.<br />

Lowest running costs on the market<br />

The water consumption in the final rinse is only about 5 litres per<br />

cycle. This is achieved through the spinning and specially designed<br />

rinse nozzles. The advanced condensing system consumes only 10<br />

% of the water volume that was previously consumed in the<br />

condensing of simi<strong>la</strong>rly sized machines. The reduced water<br />

consumption reduces the rinse aid and detergent consumption, as<br />

well as electricity consumption. Since the granule separation is based<br />

on a two-pump technology, the granules can be used longer and<br />

granule costs are reduced.