Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

226 |<br />

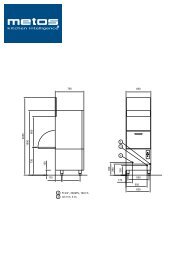

METOS WD FLIGHT-TYPE DISHWASHERS<br />

<strong>Metos</strong> WD-B flight-type dishwashers have been developed<br />

to act as the central part of our customers’ dishwashing<br />

systems. In the development work special attention has<br />

been paid to the hospitals’ strict demands on hygiene and efficiency.<br />

The profound experience <strong>Metos</strong> has in developing and manufacturing<br />

flight-type dishwashers generates a superior washing result, low<br />

operating costs and an ergonomically well-p<strong>la</strong>nned working<br />

environment. In the <strong>Metos</strong> flight-type dishwasher range you will find<br />

a machine for every application; capacities at normal speed 1900 to<br />

4600 p<strong>la</strong>tes / hour.<br />

The standard equipment includes two steplessly adjustable conveyor speeds.<br />

This enables setting the contact time according to customer needs and<br />

guarantees a sparkling washing result. The machines are also avai<strong>la</strong>ble with<br />

high-power pumps. The washing pressures can be adjusted for pot washing<br />

(pressure adjustment device is optional). A <strong>la</strong>rge range of conveyor belts is<br />

avai<strong>la</strong>ble to suit different needs. The width of the machine can be extended<br />

allowing for instance the p<strong>la</strong>cement of two GN 1/1 containers side by side.<br />

The machine is built of stainless steel that withstands heavy use and is easy<br />

to keep clean. The smooth interior surfaces can be cleaned by opening the<br />

<strong>la</strong>rge doors.The washing arms are easy to detach and clean. The outer casings<br />

of the loading and unloading areas are easily detached, allowing the areas to<br />

be rinsed. Thanks to efficient thermal insu<strong>la</strong>tion, the surface temperatures<br />

and noise levels stay low. There is also less thermal load on the working<br />

Flight-type dishwashing system equipment with returning and sorting<br />

unit in Myllypuro. Two working stations in sorting enable flexible pacing.<br />

environment, cutting the energy consumption in the venti<strong>la</strong>tion. The efficient<br />

standard heat recovery system (about 30 kW) minimizes the final fresh rinse<br />

water heating energy consumption and recycles the pump rinsing water into<br />

the intermediate rinsing in the pre-wash zone. This significantly reduces the<br />

water consumption and at the same time the rinsing and detergent costs.<br />

Standard equipment includes an extra long (1250 mm) pre-wash zone that<br />

prevents water from transferring from the pre-wash zone to the chemical<br />

zone. This way the water in the chemical tank doesn’t get diluted and<br />

unnecessary detergent consumption is avoided. Even other unwanted water<br />

transfer between tanks is eliminated with 1000 mm long washing zones.<br />

Electronic control reduces downtime due to the operator, since the machine<br />

indicates misuse on the control panel (for instance the machine tells about<br />

doors left open, objects fallen in the conveyor, temperatures etc). The control<br />

unit also makes service easier, reducing maintenance downtime. The text<br />

panel of the machine (standard equipment from <strong>Metos</strong> WD-B 76E up) or a<br />

separate service instrument gives the diagnostics in p<strong>la</strong>in <strong>la</strong>nguage to the<br />

service personnel and allows the checking of different components making<br />

problem identification easier. The control registers and collects data on the<br />

functioning of the machine, which can then be used in the development of<br />

the washing area (e.g. water consumptions, flows, temperatures etc.) This<br />

makes the rationalization of the area’s own activities easier and facilitates<br />

HACCP activities. A WD-INFO data system (optional) can be connected to<br />

the control system, allowing the collected data to be transferred to a PC. A<br />

PC makes it easy to collect statistics and for instance monitor the costs or<br />

environmental performance of the dishwashing system.<br />

Correctly dimensioned working stations improve ergonomics, speed up<br />

working and reduce fatigue. Cutlery soaking works with a lift handle.