Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

32 |<br />

METOS RG-400 VEGETABLE SLICER<br />

Basic delivery of <strong>Metos</strong> RG-400 includes the<br />

body, feed cylinder A and the hopper.<br />

The hopper feeds automatically<br />

without push feed attachment.<br />

The device is suitable for continuous<br />

feeding of round products,<br />

such as potatoes, onions, nuts, almonds<br />

and dry bread pieces - no<br />

manual pushing.<br />

■ <strong>Metos</strong> RG-400 vegetable slicer has been designed for quick handling of <strong>la</strong>rge quantities with<br />

optimal ergonomics<br />

■ <strong>Metos</strong> RG-400 is a durable, versatile and efficient vegetable slicer for the operator demanding<br />

a perfect cutting performance<br />

■ 40 kg / min < 3000 portions / day<br />

■ Ergonomic ■ Large selection of slice dimensions ■ Easy and quick to clean<br />

■ Reliable and low maintenance<br />

■ Versatile applications<br />

■ Special attention paid to safety and reliability<br />

Feed hopper<br />

The manual feed attachment is<br />

easy and light to operate when<br />

for instance cabbage, cheese, carrots<br />

and lettuce are handled.<br />

The feed hopper with its own feed cylinder (model A) for continuous feeding of potatoes, onions, dry<br />

bread pieces, nuts, mushrooms etc. Ailerons direct the products automatically to the disc and no pressing<br />

is necessary. For instance peeled potatoes can be fed into the hopper directly from a bag or a pail. The<br />

feeder is of stainless steel and the feeder cylinder of cast aluminium alloy with a stainless steel lining.<br />

Feed cylinder B<br />

The B model feeder cylinder is used with either a manual push feed attachment, a feeder with 4 openings<br />

or a pneumatic push feed attachment. Model B differs from model A in that it has 3 sharp edges inside.<br />

When either the manual or pneumatic push feed attachment is used, for instance a cabbage can be put<br />

directly into the cylinder, where the discs divide the surface and the spiral-form block screw of the disc<br />

pulls the cabbage onto the disc and makes operation easier. The <strong>la</strong>rge 7 l volume and the 200 mm<br />

opening of the feed cylinder reduce the number of fillings and make feeding of most products possible<br />

without cutting.<br />

Push feed attachment with 4 openings<br />

For continuous operations, such as the preliminary handling of cucumbers, leeks, tomatoes and citric<br />

fruits. Makes slicing easier. Used with feed cylinder B. The 4-opening feed attachment has 2 openings<br />

with 73 mm dia., one with 35 mm dia. 2 different size push rods made of white food industry p<strong>la</strong>stic are<br />

included. The attachment is made of aluminium and it has a separate lock screw for locking the discs.<br />

The 4-opening feed attachment is<br />

designed for continuous feeding<br />

of cucumbers, leeks, Romaine lettuce,<br />

celery and other lengthy<br />

products.<br />

The pneumatic push feed attachment<br />

pushes the product automatically<br />

onto the disc without manual<br />

manipu<strong>la</strong>tion. Makes handling<br />

<strong>la</strong>rge quantities easier.<br />

Manual push feed attachment<br />

For high speed operation, for instance for feeding cabbage,<br />

sprouts, iceberg lettuce, carrots, tomatoes and other<br />

products that have to be supported and pressed. The<br />

design of the attachment makes pushing lighter and no<br />

force is necessary. The running of the machine can also<br />

be controlled, since when the attachment is turned away,<br />

the machine stops and vice versa.<br />

Pneumatic push feed attachment<br />

For automatic handling of products that need to be<br />

pushed, such as cabbage, lettuce, carrots. Processing<br />

cabbage and carrots that used to be the most <strong>la</strong>bour<br />

intensive is now easy and ergonomic thanks to the<br />

pneumatic push feed attachment. The operator fills the<br />

feed cylinder (B) and rotates the attachment onto the<br />

feed cylinder which starts the machine automatically.<br />

Working is safe since the machine stops automatically<br />

when the attachment is rotated away. Choice of three<br />

speeds to match the texture of the handled product.<br />

<strong>Metos</strong> Code El. connection Delivery<br />

RG-400 4132512 400V 3N~ 1,5/0,9 kW 10A Machine body, feed hopper, feed cylinder A<br />

Feed cylinder B 4132537 used with either a manual push feed attachment, a feeder with 4 openings or a pneumatic push feed attachment<br />

4-opening feed att. 4189276 new model from Serial No. 2550<br />

Manual push feed att. 4189269 new model from Serial No. 2550<br />

Pneumatic push feed att. 4189283 Compressed air 35 l/min is required; new model from serial nr. 2550<br />

Compressor 4133146 working pressure 6 bar 1,33 l /s, 230V, 1~0,75 kW, 10 A slow, volume of the tank 19 l<br />

RG 400, 7 package 4132618 Machine body, feed hopper, feed cylinder A, manual push feed attachment,<br />

feed cylinder B, fine cut slicer 2 and 4 mm, standard slicer 10 mm,<br />

dicing grid 10x10, julienne cutter 4.5x4.5, grater/shredder 2 and 8 mm,<br />

3 wall racks<br />

Utensil trolley 4144194 860x535x1060 mm<br />

Wall rack 4087517 for 3 discs<br />

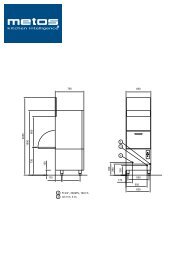

Instal<strong>la</strong>tion drawing on page 271<br />

Stock product