Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGC</strong> Rapport 2013:277<br />

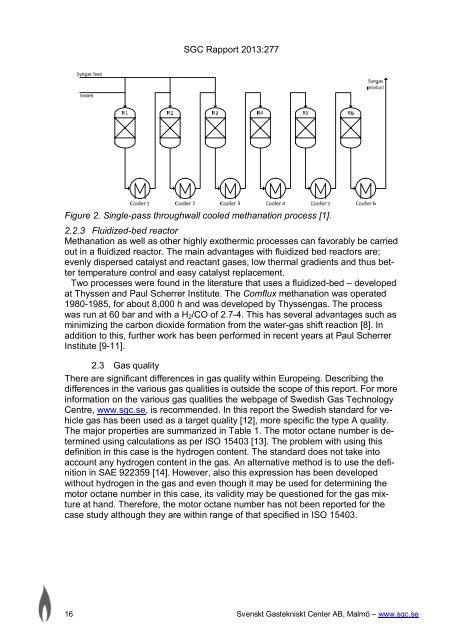

Figure 2. S<strong>in</strong>gle-pass throughwall cooled methanation process [1].<br />

2.2.3 Fluidized-bed reactor<br />

Methanation as well as other highly exothermic processes can favorably be carried<br />

out <strong>in</strong> a fluidized reactor. The ma<strong>in</strong> advantages with fluidized bed reactors are;<br />

evenly dispersed catalyst and reactant gases, low thermal gradients and thus better<br />

temperature control and easy catalyst replacement.<br />

Two processes were found <strong>in</strong> the literature that uses a fluidized-bed – developed<br />

at Thyssen and Paul Scherrer Institute. The Comflux methanation was operated<br />

1980-1985, for about 8,000 h and was developed by Thyssengas. The process<br />

was run at 60 bar and with a H2/CO of 2.7-4. This has several advantages such as<br />

m<strong>in</strong>imiz<strong>in</strong>g the carbon <strong>dioxide</strong> formation from the water-gas shift reaction [8]. In<br />

addition to this, further work has been performed <strong>in</strong> recent years at Paul Scherrer<br />

Institute [9-11].<br />

2.3 Gas quality<br />

There are significant differences <strong>in</strong> gas quality with<strong>in</strong> Europe<strong>in</strong>g. Describ<strong>in</strong>g the<br />

differences <strong>in</strong> the various gas qualities is outside the scope of this report. For more<br />

<strong>in</strong>formation on the various gas qualities the webpage of Swedish Gas Technology<br />

Centre, www.sgc.se, is recommended. In this report the Swedish standard for vehicle<br />

gas has been used as a target quality [12], more specific the type A quality.<br />

The major properties are summarized <strong>in</strong> Table 1. The motor octane number is determ<strong>in</strong>ed<br />

us<strong>in</strong>g calculations as per ISO 15403 [13]. The problem with us<strong>in</strong>g this<br />

def<strong>in</strong>ition <strong>in</strong> this case is the hydrogen content. The standard does not take <strong>in</strong>to<br />

account any hydrogen content <strong>in</strong> the gas. An alternative method is to use the def<strong>in</strong>ition<br />

<strong>in</strong> SAE 922359 [14]. However, also this expression has been developed<br />

without hydrogen <strong>in</strong> the gas and even though it may be used for determ<strong>in</strong><strong>in</strong>g the<br />

motor octane number <strong>in</strong> this case, its validity may be questioned for the gas mixture<br />

at hand. Therefore, the motor octane number has not been reported for the<br />

case study although they are with<strong>in</strong> range of that specified <strong>in</strong> ISO 15403.<br />

16 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se