Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGC</strong> Rapport 2013:277<br />

For the build<strong>in</strong>g of an accurate gas separation model, a number of fundamental<br />

physical and chemical data is required.<br />

For the physical properties of the system - such as density, viscosity, surface<br />

tension, diffusivity of the am<strong>in</strong>es <strong>in</strong> water solution, diffusivity of gases <strong>in</strong> the am<strong>in</strong>e<br />

solution, gas solubility <strong>in</strong> the am<strong>in</strong>e solution and heat capacity - data was taken<br />

from the literature [41, 55-69]. However, only one journal publication on the heat of<br />

reaction for the <strong>in</strong>vestigated system was found with very limited data [70]. The only<br />

other reference found was an <strong>in</strong>terim report from North Carol<strong>in</strong>a State University<br />

[71]. For this reason an <strong>in</strong>vestigation on the heat of reaction for the system was<br />

conducted for the MDEA/PZ-system [72]. The data acquired from this <strong>in</strong>vestigation<br />

was used <strong>in</strong> the simulation model.<br />

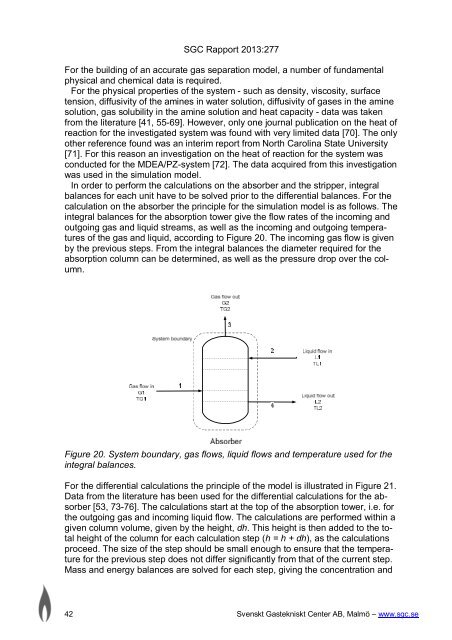

In order to perform the calculations on the absorber and the stripper, <strong>in</strong>tegral<br />

balances for each unit have to be solved prior to the differential balances. For the<br />

calculation on the absorber the pr<strong>in</strong>ciple for the simulation model is as follows. The<br />

<strong>in</strong>tegral balances for the absorption tower give the flow rates of the <strong>in</strong>com<strong>in</strong>g and<br />

outgo<strong>in</strong>g gas and liquid streams, as well as the <strong>in</strong>com<strong>in</strong>g and outgo<strong>in</strong>g temperatures<br />

of the gas and liquid, accord<strong>in</strong>g to Figure 20. The <strong>in</strong>com<strong>in</strong>g gas flow is given<br />

by the previous steps. From the <strong>in</strong>tegral balances the diameter required for the<br />

absorption column can be determ<strong>in</strong>ed, as well as the pressure drop over the column.<br />

Figure 20. System boundary, gas flows, liquid flows and temperature used for the<br />

<strong>in</strong>tegral balances.<br />

For the differential calculations the pr<strong>in</strong>ciple of the model is illustrated <strong>in</strong> Figure 21.<br />

Data from the literature has been used for the differential calculations for the absorber<br />

[53, 73-76]. The calculations start at the top of the absorption tower, i.e. for<br />

the outgo<strong>in</strong>g gas and <strong>in</strong>com<strong>in</strong>g liquid flow. The calculations are performed with<strong>in</strong> a<br />

given column volume, given by the height, dh. This height is then added to the total<br />

height of the column for each calculation step (h = h + dh), as the calculations<br />

proceed. The size of the step should be small enough to ensure that the temperature<br />

for the previous step does not differ significantly from that of the current step.<br />

Mass and energy balances are solved for each step, giv<strong>in</strong>g the concentration and<br />

42 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se