Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGC</strong> Rapport 2013:277<br />

case is the case that has the largest differences compared to traditional biogas<br />

upgrad<strong>in</strong>g as there is low methane content and high content of hydrogen and carbon<br />

monoxide <strong>in</strong> the gas, table 7.<br />

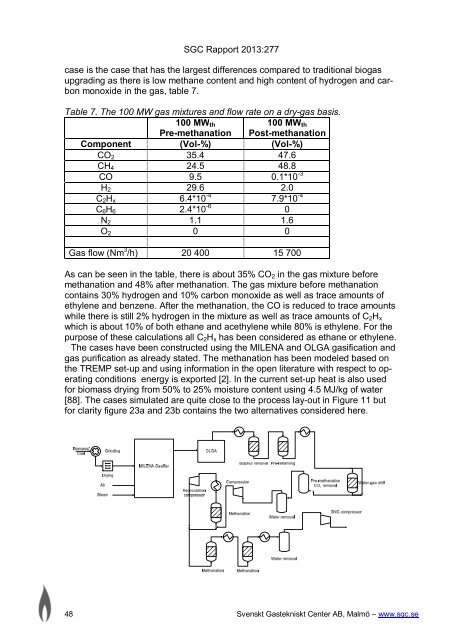

Table 7. The 100 MW gas mixtures and flow rate on a dry-gas basis.<br />

100 MWth<br />

100 MWth<br />

Pre-methanation Post-methanation<br />

Component (Vol-%) (Vol-%)<br />

CO2 35.4 47.6<br />

CH4 24.5 48.8<br />

CO 9.5 0.1*10 -3<br />

H2 29.6 2.0<br />

C2Hx<br />

C6H6<br />

6.4*10 -4<br />

2.4*10 -6<br />

7.9*10 -4<br />

0<br />

N2 1.1 1.6<br />

O2 0 0<br />

Gas flow (Nm 3 /h) 20 400 15 700<br />

As can be seen <strong>in</strong> the table, there is about 35% CO2 <strong>in</strong> the gas mixture before<br />

methanation and 48% after methanation. The gas mixture before methanation<br />

conta<strong>in</strong>s 30% hydrogen and 10% carbon monoxide as well as trace amounts of<br />

ethylene and benzene. After the methanation, the CO is reduced to trace amounts<br />

while there is still 2% hydrogen <strong>in</strong> the mixture as well as trace amounts of C2Hx<br />

which is about 10% of both ethane and acethylene while 80% is ethylene. For the<br />

purpose of these calculations all C2Hx has been considered as ethane or ethylene.<br />

The cases have been constructed us<strong>in</strong>g the MILENA and OLGA <strong>gasification</strong> and<br />

gas purification as already stated. The methanation has been modeled based on<br />

the TREMP set-up and us<strong>in</strong>g <strong>in</strong>formation <strong>in</strong> the open literature with respect to operat<strong>in</strong>g<br />

conditions energy is exported [2]. In the current set-up heat is also used<br />

for biomass dry<strong>in</strong>g from 50% to 25% moisture content us<strong>in</strong>g 4.5 MJ/kg of water<br />

[88]. The cases simulated are quite close to the process lay-out <strong>in</strong> Figure 11 but<br />

for clarity figure 23a and 23b conta<strong>in</strong>s the two alternatives considered here.<br />

48 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se