Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Summary<br />

<strong>SGC</strong> Rapport 2013:277<br />

There are two technologies for produc<strong>in</strong>g biomethane, one based on anaerobic<br />

digestion and one based on biomass <strong>gasification</strong>. Out of the two, the pathway<br />

based on anaerobic digestion is the more mature. In both cases, there is a requirement<br />

for remov<strong>in</strong>g the CO2 which is co-produced with the methane. This<br />

study <strong>in</strong>vestigates the possibilities and opportunities for us<strong>in</strong>g exist<strong>in</strong>g CO2 <strong>removal</strong><br />

technologies (water scrubb<strong>in</strong>g and am<strong>in</strong>e scrubb<strong>in</strong>g) commercialized for anaerobic<br />

digestion <strong>in</strong> the biomass <strong>gasification</strong> case.<br />

The most likely <strong>gasification</strong> technology to be used <strong>in</strong> small scale <strong>gasification</strong> for<br />

production of substitute natural gas (SNG) from biomass is the <strong>in</strong>direct gasifier.<br />

Therefore two cases based on different gasifier technologies have been <strong>in</strong>vestigated.<br />

The <strong>in</strong>vestigation has been performed us<strong>in</strong>g exist<strong>in</strong>g models for <strong>gasification</strong><br />

and CO2 separation which have been used together <strong>in</strong> an iterative fashion to close<br />

the heat and mass balances for the systems. The two cases have been 10 MWth<br />

and 100 MWth <strong>in</strong>put of biomass with 50% moisture content. In the larger case, the<br />

methanation is performed <strong>in</strong> a fixed multi-stage bed while <strong>in</strong> the smaller case the<br />

methanation is performed <strong>in</strong> a mov<strong>in</strong>g bed reactor. The systems have been evaluated<br />

for efficiency and assessed for export<strong>in</strong>g the product to the natural gas grid <strong>in</strong><br />

a Swedish context. The major f<strong>in</strong>d<strong>in</strong>gs <strong>in</strong> the report are summarized <strong>in</strong> table S.1.<br />

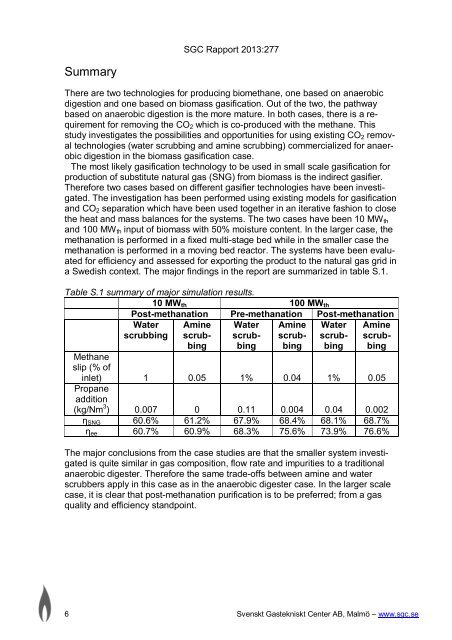

Table S.1 summary of major simulation results.<br />

10 MWth<br />

100 MWth<br />

Post-methanation Pre-methanation Post-methanation<br />

Water<br />

scrubb<strong>in</strong>g<br />

Am<strong>in</strong>e<br />

scrubb<strong>in</strong>g<br />

Water<br />

scrubb<strong>in</strong>g<br />

Am<strong>in</strong>e<br />

scrubb<strong>in</strong>g<br />

Water<br />

scrubb<strong>in</strong>g<br />

Am<strong>in</strong>e<br />

scrubb<strong>in</strong>g<br />

Methane<br />

slip (% of<br />

<strong>in</strong>let) 1 0.05 1% 0.04 1% 0.05<br />

Propane<br />

addition<br />

(kg/Nm 3 ) 0.007 0 0.11 0.004 0.04 0.002<br />

ηSNG 60.6% 61.2% 67.9% 68.4% 68.1% 68.7%<br />

ηee 60.7% 60.9% 68.3% 75.6% 73.9% 76.6%<br />

The major conclusions from the case studies are that the smaller system <strong>in</strong>vestigated<br />

is quite similar <strong>in</strong> gas composition, flow rate and impurities to a traditional<br />

anaerobic digester. Therefore the same trade-offs between am<strong>in</strong>e and water<br />

scrubbers apply <strong>in</strong> this case as <strong>in</strong> the anaerobic digester case. In the larger scale<br />

case, it is clear that post-methanation purification is to be preferred; from a gas<br />

quality and efficiency standpo<strong>in</strong>t.<br />

6 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se