Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Percent by Volume<br />

30%<br />

25%<br />

20%<br />

15%<br />

10%<br />

5%<br />

0%<br />

LT-step<br />

<strong>in</strong>let CO<br />

<strong>SGC</strong> Rapport 2013:277<br />

HT-step<br />

<strong>in</strong>let CO<br />

LT-step<br />

outlet CO<br />

0 100 200 300 400 500 600 700<br />

Temperature (°C)<br />

HT-step<br />

outlet CO<br />

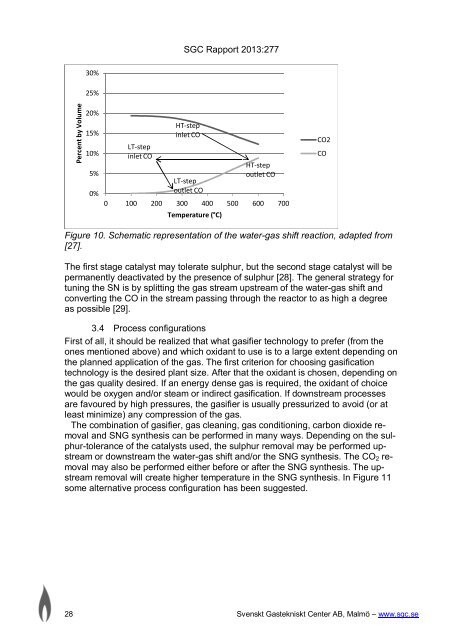

Figure 10. Schematic representation of the water-gas shift reaction, adapted from<br />

[27].<br />

The first stage catalyst may tolerate sulphur, but the second stage catalyst will be<br />

permanently deactivated by the presence of sulphur [28]. The general strategy for<br />

tun<strong>in</strong>g the SN is by splitt<strong>in</strong>g the gas stream upstream of the water-gas shift and<br />

convert<strong>in</strong>g the CO <strong>in</strong> the stream pass<strong>in</strong>g through the reactor to as high a degree<br />

as possible [29].<br />

3.4 Process configurations<br />

First of all, it should be realized that what gasifier technology to prefer (from the<br />

ones mentioned above) and which oxidant to use is to a large extent depend<strong>in</strong>g on<br />

the planned application of the gas. The first criterion for choos<strong>in</strong>g <strong>gasification</strong><br />

technology is the desired plant size. After that the oxidant is chosen, depend<strong>in</strong>g on<br />

the gas quality desired. If an energy dense gas is required, the oxidant of choice<br />

would be oxygen and/or steam or <strong>in</strong>direct <strong>gasification</strong>. If downstream processes<br />

are favoured by high pressures, the gasifier is usually pressurized to avoid (or at<br />

least m<strong>in</strong>imize) any compression of the gas.<br />

The comb<strong>in</strong>ation of gasifier, gas clean<strong>in</strong>g, gas condition<strong>in</strong>g, carbon <strong>dioxide</strong> <strong>removal</strong><br />

and SNG synthesis can be performed <strong>in</strong> many ways. Depend<strong>in</strong>g on the sulphur-tolerance<br />

of the catalysts used, the sulphur <strong>removal</strong> may be performed upstream<br />

or downstream the water-gas shift and/or the SNG synthesis. The CO2 <strong>removal</strong><br />

may also be performed either before or after the SNG synthesis. The upstream<br />

<strong>removal</strong> will create higher temperature <strong>in</strong> the SNG synthesis. In Figure 11<br />

some alternative process configuration has been suggested.<br />

28 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se<br />

CO2<br />

CO