Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SGC</strong> Rapport 2013:277<br />

4.1.3 Dimethylether of polyethylene glycol (Selexol process)<br />

The Selexol process uses dimethyl ethers of polyethylene glycol as the solvent for<br />

absorption of carbon <strong>dioxide</strong>. The Selexol solvent has a high capacity for absorption<br />

of impurities such as sulfur impurities, mercaptans, as well as ammonia, HCN<br />

and other higher hydrocarbons.<br />

H2S is up to n<strong>in</strong>e times more soluble <strong>in</strong> the Selexol solvent than CO2, which<br />

makes it suitable for selective <strong>removal</strong> of H2S. Hydrocarbons are also very soluble<br />

<strong>in</strong> the solvent and the solubility <strong>in</strong>creases with <strong>in</strong>creas<strong>in</strong>g molecular weight. Water<br />

is also highly soluble <strong>in</strong> the Selexol solvent. Due to this quality the Selexol process<br />

is often used for simultaneous hydrocarbon and water dew po<strong>in</strong>t control [34].<br />

4.1.4 Water scrubb<strong>in</strong>g<br />

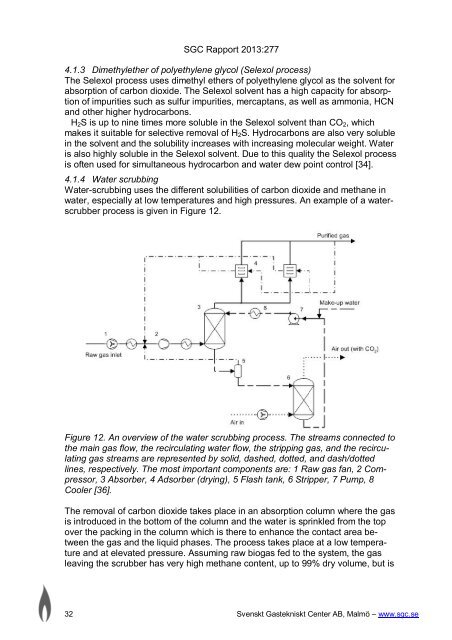

Water-scrubb<strong>in</strong>g uses the different solubilities of carbon <strong>dioxide</strong> and methane <strong>in</strong><br />

water, especially at low temperatures and high pressures. An example of a waterscrubber<br />

process is given <strong>in</strong> Figure 12.<br />

Figure 12. An overview of the water scrubb<strong>in</strong>g process. The streams connected to<br />

the ma<strong>in</strong> gas flow, the recirculat<strong>in</strong>g water flow, the stripp<strong>in</strong>g gas, and the recirculat<strong>in</strong>g<br />

gas streams are represented by solid, dashed, dotted, and dash/dotted<br />

l<strong>in</strong>es, respectively. The most important components are: 1 Raw gas fan, 2 Compressor,<br />

3 Absorber, 4 Adsorber (dry<strong>in</strong>g), 5 Flash tank, 6 Stripper, 7 Pump, 8<br />

Cooler [36].<br />

The <strong>removal</strong> of carbon <strong>dioxide</strong> takes place <strong>in</strong> an absorption column where the gas<br />

is <strong>in</strong>troduced <strong>in</strong> the bottom of the column and the water is spr<strong>in</strong>kled from the top<br />

over the pack<strong>in</strong>g <strong>in</strong> the column which is there to enhance the contact area between<br />

the gas and the liquid phases. The process takes place at a low temperature<br />

and at elevated pressure. Assum<strong>in</strong>g raw biogas fed to the system, the gas<br />

leav<strong>in</strong>g the scrubber has very high methane content, up to 99% dry volume, but is<br />

32 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se