Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SGC</strong> Rapport 2013:277<br />

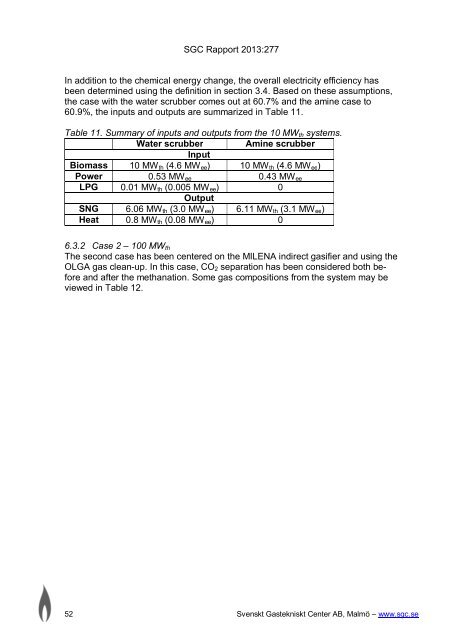

In addition to the chemical energy change, the overall electricity efficiency has<br />

been determ<strong>in</strong>ed us<strong>in</strong>g the def<strong>in</strong>ition <strong>in</strong> section 3.4. Based on these assumptions,<br />

the case with the water scrubber comes out at 60.7% and the am<strong>in</strong>e case to<br />

60.9%, the <strong>in</strong>puts and outputs are summarized <strong>in</strong> Table 11.<br />

Table 11. Summary of <strong>in</strong>puts and outputs from the 10 MWth systems.<br />

Water scrubber Am<strong>in</strong>e scrubber<br />

Input<br />

Biomass 10 MWth (4.6 MWee) 10 MWth (4.6 MWee)<br />

Power 0.53 MWee 0.43 MWee<br />

LPG 0.01 MWth (0.005 MWee) 0<br />

Output<br />

SNG 6.06 MWth (3.0 MWee) 6.11 MWth (3.1 MWee)<br />

Heat 0.8 MWth (0.08 MWee) 0<br />

6.3.2 Case 2 – 100 MWth<br />

The second case has been centered on the MILENA <strong>in</strong>direct gasifier and us<strong>in</strong>g the<br />

OLGA gas clean-up. In this case, CO2 separation has been considered both before<br />

and after the methanation. Some gas compositions from the system may be<br />

viewed <strong>in</strong> Table 12.<br />

52 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se