Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SGC</strong> Rapport 2013:277<br />

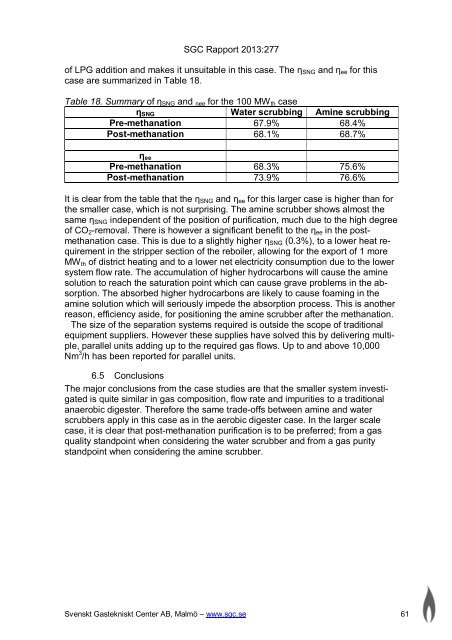

of LPG addition and makes it unsuitable <strong>in</strong> this case. The ηSNG and ηee for this<br />

case are summarized <strong>in</strong> Table 18.<br />

Table 18. Summary of ηSNG and ηee for the 100 MWth case<br />

ηSNG Water scrubb<strong>in</strong>g Am<strong>in</strong>e scrubb<strong>in</strong>g<br />

Pre-methanation 67.9% 68.4%<br />

Post-methanation 68.1% 68.7%<br />

ηee<br />

Pre-methanation 68.3% 75.6%<br />

Post-methanation 73.9% 76.6%<br />

It is clear from the table that the ηSNG and ηee for this larger case is higher than for<br />

the smaller case, which is not surpris<strong>in</strong>g. The am<strong>in</strong>e scrubber shows almost the<br />

same ηSNG <strong>in</strong>dependent of the position of purification, much due to the high degree<br />

of CO2-<strong>removal</strong>. There is however a significant benefit to the ηee <strong>in</strong> the postmethanation<br />

case. This is due to a slightly higher ηSNG (0.3%), to a lower heat requirement<br />

<strong>in</strong> the stripper section of the reboiler, allow<strong>in</strong>g for the export of 1 more<br />

MWth of district heat<strong>in</strong>g and to a lower net electricity consumption due to the lower<br />

system flow rate. The accumulation of higher hydrocarbons will cause the am<strong>in</strong>e<br />

solution to reach the saturation po<strong>in</strong>t which can cause grave problems <strong>in</strong> the absorption.<br />

The absorbed higher hydrocarbons are likely to cause foam<strong>in</strong>g <strong>in</strong> the<br />

am<strong>in</strong>e solution which will seriously impede the absorption process. This is another<br />

reason, efficiency aside, for position<strong>in</strong>g the am<strong>in</strong>e scrubber after the methanation.<br />

The size of the separation systems required is outside the scope of traditional<br />

equipment suppliers. However these supplies have solved this by deliver<strong>in</strong>g multiple,<br />

parallel units add<strong>in</strong>g up to the required gas flows. Up to and above 10,000<br />

Nm 3 /h has been reported for parallel units.<br />

6.5 Conclusions<br />

The major conclusions from the case studies are that the smaller system <strong>in</strong>vestigated<br />

is quite similar <strong>in</strong> gas composition, flow rate and impurities to a traditional<br />

anaerobic digester. Therefore the same trade-offs between am<strong>in</strong>e and water<br />

scrubbers apply <strong>in</strong> this case as <strong>in</strong> the aerobic digester case. In the larger scale<br />

case, it is clear that post-methanation purification is to be preferred; from a gas<br />

quality standpo<strong>in</strong>t when consider<strong>in</strong>g the water scrubber and from a gas purity<br />

standpo<strong>in</strong>t when consider<strong>in</strong>g the am<strong>in</strong>e scrubber.<br />

Svenskt Gastekniskt Center AB, Malmö – www.sgc.se 61