Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SGC</strong> Rapport 2013:277<br />

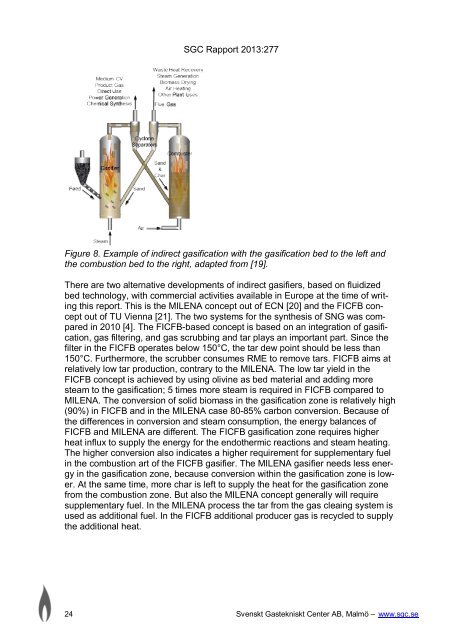

Figure 8. Example of <strong>in</strong>direct <strong>gasification</strong> with the <strong>gasification</strong> bed to the left and<br />

the combustion bed to the right, adapted from [19].<br />

There are two alternative developments of <strong>in</strong>direct gasifiers, based on fluidized<br />

bed technology, with commercial activities available <strong>in</strong> Europe at the time of writ<strong>in</strong>g<br />

this report. This is the MILENA concept out of ECN [20] and the FICFB concept<br />

out of TU Vienna [21]. The two systems for the synthesis of SNG was compared<br />

<strong>in</strong> 2010 [4]. The FICFB-based concept is based on an <strong>in</strong>tegration of <strong>gasification</strong>,<br />

gas filter<strong>in</strong>g, and gas scrubb<strong>in</strong>g and tar plays an important part. S<strong>in</strong>ce the<br />

filter <strong>in</strong> the FICFB operates below 150°C, the tar dew po<strong>in</strong>t should be less than<br />

150°C. Furthermore, the scrubber consumes RME to remove tars. FICFB aims at<br />

relatively low tar production, contrary to the MILENA. The low tar yield <strong>in</strong> the<br />

FICFB concept is achieved by us<strong>in</strong>g oliv<strong>in</strong>e as bed material and add<strong>in</strong>g more<br />

steam to the <strong>gasification</strong>; 5 times more steam is required <strong>in</strong> FICFB compared to<br />

MILENA. The conversion of solid biomass <strong>in</strong> the <strong>gasification</strong> zone is relatively high<br />

(90%) <strong>in</strong> FICFB and <strong>in</strong> the MILENA case 80-85% carbon conversion. Because of<br />

the differences <strong>in</strong> conversion and steam consumption, the energy balances of<br />

FICFB and MILENA are different. The FICFB <strong>gasification</strong> zone requires higher<br />

heat <strong>in</strong>flux to supply the energy for the endothermic reactions and steam heat<strong>in</strong>g.<br />

The higher conversion also <strong>in</strong>dicates a higher requirement for supplementary fuel<br />

<strong>in</strong> the combustion art of the FICFB gasifier. The MILENA gasifier needs less energy<br />

<strong>in</strong> the <strong>gasification</strong> zone, because conversion with<strong>in</strong> the <strong>gasification</strong> zone is lower.<br />

At the same time, more char is left to supply the heat for the <strong>gasification</strong> zone<br />

from the combustion zone. But also the MILENA concept generally will require<br />

supplementary fuel. In the MILENA process the tar from the gas clea<strong>in</strong>g system is<br />

used as additional fuel. In the FICFB additional producer gas is recycled to supply<br />

the additional heat.<br />

24 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se