Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Carbon dioxide removal in indirect gasification - SGC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>SGC</strong> Rapport 2013:277<br />

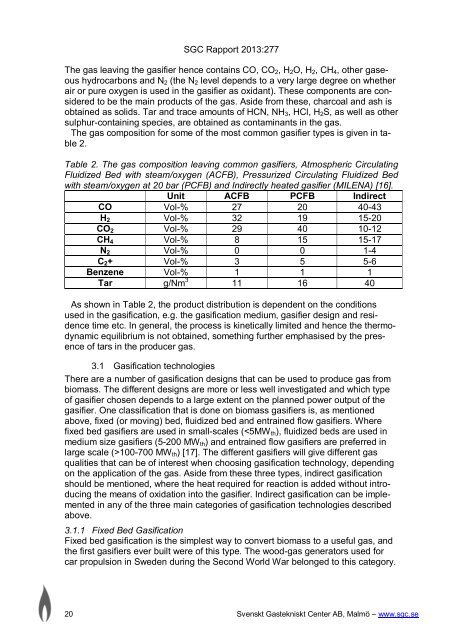

The gas leav<strong>in</strong>g the gasifier hence conta<strong>in</strong>s CO, CO2, H2O, H2, CH4, other gaseous<br />

hydrocarbons and N2 (the N2 level depends to a very large degree on whether<br />

air or pure oxygen is used <strong>in</strong> the gasifier as oxidant). These components are considered<br />

to be the ma<strong>in</strong> products of the gas. Aside from these, charcoal and ash is<br />

obta<strong>in</strong>ed as solids. Tar and trace amounts of HCN, NH3, HCl, H2S, as well as other<br />

sulphur-conta<strong>in</strong><strong>in</strong>g species, are obta<strong>in</strong>ed as contam<strong>in</strong>ants <strong>in</strong> the gas.<br />

The gas composition for some of the most common gasifier types is given <strong>in</strong> table<br />

2.<br />

Table 2. The gas composition leav<strong>in</strong>g common gasifiers, Atmospheric Circulat<strong>in</strong>g<br />

Fluidized Bed with steam/oxygen (ACFB), Pressurized Circulat<strong>in</strong>g Fluidized Bed<br />

with steam/oxygen at 20 bar (PCFB) and Indirectly heated gasifier (MILENA) [16].<br />

Unit ACFB PCFB Indirect<br />

CO Vol-% 27 20 40-43<br />

H2 Vol-% 32 19 15-20<br />

CO2 Vol-% 29 40 10-12<br />

CH4 Vol-% 8 15 15-17<br />

N2 Vol-% 0 0 1-4<br />

C2+ Vol-% 3 5 5-6<br />

Benzene Vol-% 1 1 1<br />

Tar g/Nm 3<br />

11 16 40<br />

As shown <strong>in</strong> Table 2, the product distribution is dependent on the conditions<br />

used <strong>in</strong> the <strong>gasification</strong>, e.g. the <strong>gasification</strong> medium, gasifier design and residence<br />

time etc. In general, the process is k<strong>in</strong>etically limited and hence the thermodynamic<br />

equilibrium is not obta<strong>in</strong>ed, someth<strong>in</strong>g further emphasised by the presence<br />

of tars <strong>in</strong> the producer gas.<br />

3.1 Gasification technologies<br />

There are a number of <strong>gasification</strong> designs that can be used to produce gas from<br />

biomass. The different designs are more or less well <strong>in</strong>vestigated and which type<br />

of gasifier chosen depends to a large extent on the planned power output of the<br />

gasifier. One classification that is done on biomass gasifiers is, as mentioned<br />

above, fixed (or mov<strong>in</strong>g) bed, fluidized bed and entra<strong>in</strong>ed flow gasifiers. Where<br />

fixed bed gasifiers are used <strong>in</strong> small-scales (100-700 MWth) [17]. The different gasifiers will give different gas<br />

qualities that can be of <strong>in</strong>terest when choos<strong>in</strong>g <strong>gasification</strong> technology, depend<strong>in</strong>g<br />

on the application of the gas. Aside from these three types, <strong>in</strong>direct <strong>gasification</strong><br />

should be mentioned, where the heat required for reaction is added without <strong>in</strong>troduc<strong>in</strong>g<br />

the means of oxidation <strong>in</strong>to the gasifier. Indirect <strong>gasification</strong> can be implemented<br />

<strong>in</strong> any of the three ma<strong>in</strong> categories of <strong>gasification</strong> technologies described<br />

above.<br />

3.1.1 Fixed Bed Gasification<br />

Fixed bed <strong>gasification</strong> is the simplest way to convert biomass to a useful gas, and<br />

the first gasifiers ever built were of this type. The wood-gas generators used for<br />

car propulsion <strong>in</strong> Sweden dur<strong>in</strong>g the Second World War belonged to this category.<br />

20 Svenskt Gastekniskt Center AB, Malmö – www.sgc.se