- Page 1 and 2:

SYNTHESIS AND CHARACTERIZATION OF L

- Page 3 and 4:

STATEMENT BY AUTHOR This dissertati

- Page 5 and 6:

Dedicated to ……… My beloved b

- Page 7 and 8:

also thankful to all the members of

- Page 9 and 10:

2.3 Synthesis of binary oxide nanom

- Page 11 and 12:

CHAPTER 5: Zinc Gallate ...........

- Page 13 and 14:

imaging, scintillators, lasers, etc

- Page 15 and 16:

morphology by heating at 500 and 90

- Page 17 and 18:

nanoparticles having hexagonal stru

- Page 19 and 20:

100°C and 185°C, respectively in

- Page 21 and 22:

into poly methyl methacryllate (PMM

- Page 23 and 24:

3. N. M. Dimitrijevic, Z. V. Saponj

- Page 25 and 26:

Fig.13: Fig.14: (a) Simplified ray

- Page 27 and 28:

Eu 3+ ions after heat treatment at

- Page 29 and 30:

615 nm Fig.50: FT-IR patterns (a) a

- Page 31 and 32: area electron diffraction pattern a

- Page 33 and 34: different amounts of Eu 3+ . Fig.86

- Page 35 and 36: and 545 nm, respectively. Fig.106:

- Page 37 and 38: List of Tables: Table 1: Variation

- Page 39 and 40: CHAPTER 1: Introduction 1.1 Histori

- Page 41 and 42: Rods, cylinders, wires and tubes ar

- Page 43 and 44: must be supersaturated either by di

- Page 45 and 46: - + - + charge stabilized nanoparti

- Page 47 and 48: exothermic reaction between the met

- Page 49 and 50: constant, ħ is h/2π, e is the ele

- Page 51 and 52: these platinum complexes have been

- Page 53 and 54: (IR), visible and ultra-violet (UV)

- Page 55 and 56: in Ce 3+ , Pr 3+ , Tb 3+ and CT abs

- Page 57 and 58: assisted by lattice phonons of appr

- Page 59 and 60: decay-time reduction is much easier

- Page 61 and 62: nanocrystals is shown in Fig.10 [58

- Page 63 and 64: depends strongly on the nature of t

- Page 65 and 66: corresponding emission and excitati

- Page 67 and 68: doped nanomaterials of the above me

- Page 69 and 70: will be formed and subsequently it

- Page 71 and 72: Eu 3+ ions were also subjected to s

- Page 73 and 74: transferred into a two-necked RB fl

- Page 75 and 76: Where λ is the wavelength of X-ray

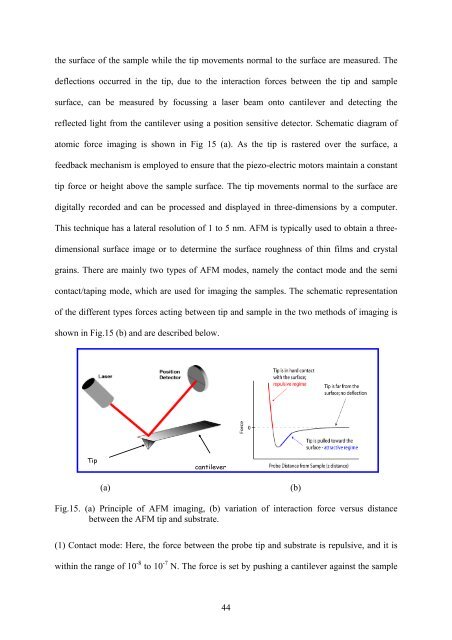

- Page 77 and 78: Micro-structural characterization b

- Page 79 and 80: electrons (i.e. diffraction mode).

- Page 81: diffraction spots. By tilting a cry

- Page 85 and 86: three types lines in the scattered

- Page 87 and 88: solids tend to be broadened because

- Page 89 and 90: sample fluoresce. The fluorescent l

- Page 91 and 92: pulse frequency) as excitation sour

- Page 93 and 94: Lanthanide ions doped Ga 2 O 3 nano

- Page 95 and 96: atoms at three corners and the lone

- Page 97 and 98: Figure 19 (a-d) shows SEM images of

- Page 99 and 100: Based on these results, it can be i

- Page 101 and 102: almost normal to the equatorial pla

- Page 103 and 104: Table 2. Summary of important modes

- Page 105 and 106: systematic disappearance of these t

- Page 107 and 108: comparison, Eu 3+ ions alone in wat

- Page 109 and 110: the samples, suggesting that Eu 3+

- Page 111 and 112: These inferences are further substa

- Page 113 and 114: Similar DTA peaks have been reporte

- Page 115 and 116: GaOOH samples doped with different

- Page 117 and 118: The cell parameters increases with

- Page 119 and 120: strong emission compared to corresp

- Page 121 and 122: curves are shown in Fig.39. Lifetim

- Page 123 and 124: Similar results are also observed f

- Page 125 and 126: intensity of XRD peaks correspond t

- Page 127 and 128: compared to the bulk material and a

- Page 129 and 130: is almost 1½ times that of peak B1

- Page 131 and 132: 3.8 Interaction of Eu 3+ ions with

- Page 133 and 134:

The spectrum shows strong emission

- Page 135 and 136:

The decay curves are found to be bi

- Page 137 and 138:

As prepared undoped Sb 2 O 3 sample

- Page 139 and 140:

Intensity(arb.units) 1.0 0.8 0.6 0.

- Page 141 and 142:

3+ having surface lanthanide ions.

- Page 143 and 144:

diffraction patterns from the GaPO

- Page 145 and 146:

5 D 0 7 F 2 level to 7 F 7 7 1 , F

- Page 147 and 148:

The second possibility is the excha

- Page 149 and 150:

chemical shift anisotropy is much h

- Page 151 and 152:

not have strong interaction with th

- Page 153 and 154:

(001) (110) (011) (101) (020) (101)

- Page 155 and 156:

growth centre compared to higher vi

- Page 157 and 158:

observed after excitation at 250 an

- Page 159 and 160:

3+ 3+ concentration quenching. Tb l

- Page 161 and 162:

Compared to the selected area elect

- Page 163 and 164:

lattice. Lanthanide ions occupying

- Page 165 and 166:

obtained after 275 nm excitation is

- Page 167 and 168:

The luminescence dynamics associate

- Page 169 and 170:

that the broad peak can be resolved

- Page 171 and 172:

espectively. Value of this integral

- Page 173 and 174:

ethylene glycol moiety (stabilizing

- Page 175 and 176:

Room temperature and 100°C synthes

- Page 177 and 178:

heavier metal ion as compared to La

- Page 179 and 180:

Similar studies were also carried o

- Page 181 and 182:

3+ 3+ faster decay component is ass

- Page 183 and 184:

the other hand the Eu 3+ lifetime h

- Page 185 and 186:

3+ 4.4.8 Luminescence studies on Sm

- Page 187 and 188:

CHAPTER 5: Zinc gallate (ZnGa 2 O 4

- Page 189 and 190:

In pure EG an amorphous product is

- Page 191 and 192:

water content in the reaction mediu

- Page 193 and 194:

nucleation, thereby leading to incr

- Page 195 and 196:

particles. Thus the TEM studies als

- Page 197 and 198:

value. The lattice parameters calcu

- Page 199 and 200:

Quantum yield of the blue emission

- Page 201 and 202:

5.5.2. Eu 3+ doped ZnGa 1.5 In 0.5

- Page 203 and 204:

CHAPTER 6: Tungstates [MWO 4 (M = C

- Page 205 and 206:

ionic radius of the metal cation ca

- Page 207 and 208:

lattice. Asymmetric ratio is ~ 12 f

- Page 209 and 210:

700 Intensity (arb.units) 600 λ ex

- Page 211 and 212:

Intensity (arb.units) 25000 20000 1

- Page 213 and 214:

Strong green emission has been obse

- Page 215 and 216:

consists of strong band at 255 nm a

- Page 217 and 218:

peak can be attributed to the cryst

- Page 219 and 220:

nm) is observed from Er 3+ doped Ga

- Page 221 and 222:

and Dy 3+ doped CaWO 4 nanoparticle

- Page 223 and 224:

REFERENCES 1. D. J. Barber, I. C. F

- Page 225 and 226:

32. K. A. Gschneidner, Jr., L. Eyri

- Page 227 and 228:

65. Z. Deng, F. Tang, D. Chen, X. M

- Page 229 and 230:

100. A. Rouanel, J. J. Serra, K. Al

- Page 231 and 232:

130. F. Li, W. Jianhuai, L. Jiongti

- Page 233 and 234:

166. L. Fu, Z. Liu, Y. Liu, B. Han,

- Page 235 and 236:

205. R. Sasikala, V. Sudarsan, C. S

- Page 237 and 238:

238. E. Oldfield, R. A. Kinsey, K.

- Page 239 and 240:

271. B. G. Hyde, S. Andersson, ”I

- Page 241 and 242:

B. S. Naidu, B. Vishwanadh, V. Suda

- Page 243:

9. Room temperature synthesis of mu