PDF [4833KB] - Sony

PDF [4833KB] - Sony

PDF [4833KB] - Sony

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Promoting a worldwide EMCS structure: Overhauling engineering and manufacturing<br />

frameworks to reflect distinctive regional needs on a global scale<br />

Rethinking global engineering, manufacturing,<br />

distribution and service functions<br />

As part of “Transformation 60,” <strong>Sony</strong> is busy<br />

reshaping its product creation structure into a<br />

more knowledge-intensive model. For its worldwide<br />

operations, <strong>Sony</strong> has introduced a new<br />

engineering and production platform called EMCS<br />

(representing engineering, manufacturing and<br />

customer services). From the ground up, <strong>Sony</strong> is<br />

completing a comprehensive review of its production<br />

network, which had been structured to manufacture<br />

products within each region. The intent is<br />

to overhaul the engineering and manufacturing<br />

frameworks to better reflect the distinct features of<br />

each region, and simultaneously increase the added<br />

value generated by these frameworks. Maximizing<br />

the integration of global functions from engineering<br />

through manufacturing, distribution and customer<br />

service will foster an environment for the<br />

global implementation of an advanced supply<br />

chain management (SCM) system. <strong>Sony</strong> plans to<br />

convert some of its manufacturing facilities into<br />

Customer Front Centers (CFC). By improving distribution<br />

and service capabilities, these centers will<br />

enable <strong>Sony</strong> to further upgrade various customer<br />

services and respond even more efficiently to<br />

consumer needs.<br />

<strong>Sony</strong> seeks to reinforce its engineering framework<br />

and refine its ability to manufacture value-added<br />

components, such as semiconductors, in turn<br />

enhancing its mounting processes and helping to<br />

create new state-of-the-art products. Producing a<br />

steady flow of new products that use leadingedge<br />

components, hence giving them a distinctly<br />

<strong>Sony</strong> feel, will be central to the future of <strong>Sony</strong>’s<br />

electronics business.<br />

Regional production strategies that mirror<br />

market needs<br />

<strong>Sony</strong>’s strategy for its global production bases is<br />

to deepen ties between manufacturing activities<br />

in Japan, China and elsewhere in Asia. <strong>Sony</strong> is<br />

increasing production of finished goods in China in<br />

anticipation of continued rapid growth in demand,<br />

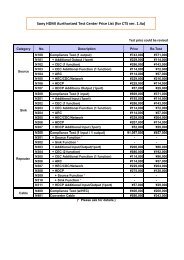

Production Locations and Destinations of Electronics Products<br />

Europe<br />

China<br />

SE Asia<br />

as well as increasing the output of both costcompetitive,<br />

mass-produced products for export<br />

and components and modules associated with<br />

operations in Japan. Products that are manufactured<br />

price-competitively in other parts of Asia<br />

are exported to Japan, Europe and the U.S. as well<br />

as supplied within the region itself. To enhance<br />

responsiveness to customer needs in each<br />

region, CFC functions are also being added to<br />

Asian manufacturing sites. In Europe and the<br />

U.S., two of <strong>Sony</strong>’s major markets, the current<br />

single-category mass-production framework will<br />

be complemented by adding CFC functions, thus<br />

enabling a faster response to market needs<br />

while strengthening manufacturing and sales<br />

activities within each region.<br />

Japan <br />

North<br />

America<br />

Raising Japan’s profile as a source of advanced<br />

technology<br />

Through the creation of its new EMCS-based<br />

structure, <strong>Sony</strong> has made Japan a focal point for<br />

sophisticated technology. By forming close ties<br />

between its development and engineering teams,<br />

Production<br />

Destination<br />

*Size of circle represents scale of production<br />

■ Japan<br />

■ North America<br />

■ Europe<br />

■ SE Asia<br />

■ China<br />

A new information system that integrates sales, manufacturing and distribution<br />

• Prepares highly accurate sales forecasts based on actual results through collaboration<br />

with distribution operations<br />

• Performs real-time monitoring of retail sales and inventories and uses this data to<br />

create an optimal manufacturing and supply system<br />

• Provides highly accurate responses to inquiries for delivery times by combining manufacturer<br />

inventory data with manufacturing plans<br />

• Constructs a logistics system that minimizes manufacturer inventories<br />

• Expands the scope of weekly management operations to increase responsiveness to<br />

rapid shifts in sales trends and other events<br />

Utilizing demand chain management to create a product supply framework that<br />

responds immediately to sales data<br />

CLOVER comes into operation: A new information system supporting the integration<br />

of sales, manufacturing and distribution operations<br />

Retail stores<br />

SMOJ<br />

SONY<br />

Corp.<br />

SSCS<br />

EMCS<br />

Components suppliers<br />

Overseas manufacturing sites and suppliers<br />

The new CLOVER information system began operating in May 2004. Adopted by <strong>Sony</strong> Corporation, <strong>Sony</strong><br />

Marketing (Japan) Inc. (SMOJ), <strong>Sony</strong> EMCS Corporation (EMCS) and <strong>Sony</strong> Supply Chain Solutions, Inc.<br />

(SSCS), the new system integrates sales, manufacturing and distribution operations to give <strong>Sony</strong> a competitive<br />

edge in Japan. CLOVER provides sophisticated data links between individual operations, facilitating<br />

demand chain management with the aim of creating an enhanced flexible product supply system that<br />

responds immediately to changes in actual retail sales data. Key benefits are greater customer satisfaction,<br />

minimal loss of sales opportunities, and lower inventories at manufacturing sites and in distribution<br />

channels. <strong>Sony</strong> expects CLOVER to produce cost savings and inventory reductions in Japan.<br />

Information<br />

Products<br />

29

![PDF [4833KB] - Sony](https://img.yumpu.com/26420643/31/500x640/pdf-4833kb-sony.jpg)