PDF [4833KB] - Sony

PDF [4833KB] - Sony

PDF [4833KB] - Sony

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

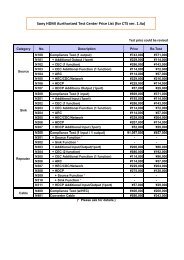

Staff wearing particle-free suits called Clean Suits<br />

Electrical testing after packaging<br />

One of the world’s most advanced<br />

semiconductor fabs<br />

Nagasaki Fab started out as the semiconductor<br />

production base of <strong>Sony</strong> Computer Entertainment<br />

Inc. (SCE), producing advanced LSIs for<br />

PlayStation 2 (PS2), notably the Graphics<br />

Synthesizer (GS), a high performance graphic<br />

rendering processor. Fab 1 began operations in<br />

spring of 2000 and Fab 2 in spring of 2001.<br />

Since then, <strong>Sony</strong> has continued to upgrade<br />

both fabs with the latest production equipment.<br />

The two fabs have a total of three clean<br />

rooms. Fab 1 produces chips on 200mm wafers<br />

using 0.18–0.15 micrometer processes (one<br />

micrometer equals 1/1,000 of one mm). On the<br />

upper level of Fab 2, another line processes<br />

200mm wafers utilizing 90 nanometer (one<br />

nanometer equals 1/1,000 of a micrometer)<br />

technology. As of spring 2004, there were only<br />

a few fabs in the global semiconductor industry<br />

using a 90 nanometer mass-production<br />

process, giving Nagasaki Fab recognition as<br />

one of the world’s most advanced wafer fabs.<br />

A vital strategic base for the <strong>Sony</strong> Group<br />

In November 2003, the Semiconductor<br />

Solutions Network Company (SSNC) was<br />

established within <strong>Sony</strong> Corporation. This<br />

gave the <strong>Sony</strong> Group an integrated framework<br />

within which to implement its semiconductor<br />

strategy, including semiconductor<br />

development and design. In order to further<br />

enhance and integrate its semiconductor manufacturing<br />

operations, SCE’s semiconductor<br />

production business will be merged with <strong>Sony</strong><br />

Semiconductor Kyushu Corporation (SCK) in<br />

July 2004 (meaning that SCK will now be<br />

responsible for all production operations). In<br />

areas such as production, personnel and<br />

technology, the two units already have a<br />

history of extremely close cooperation. Formal<br />

integration is expected to deepen these ties,<br />

strengthening <strong>Sony</strong>’s semiconductor production<br />

system and further enhancing the efficiency<br />

of its operations.<br />

Cumulative capital investments in Nagasaki<br />

Fab through March 2004 totaled approximately<br />

¥290 billion. The fab is now equipped<br />

with the most advanced semiconductor process<br />

technology in the world. Since the fiscal<br />

year ended March 31, 2004, Nagasaki Fab<br />

has been preparing for 300mm wafer, 65<br />

nanometer process technology production<br />

lines on the lower level of Fab 2. This will<br />

enable fabrication of many sophisticated processors<br />

that will inevitably be at the heart of<br />

next generation digital consumer electronics<br />

products and computer entertainment system.<br />

Nagasaki Fab will be increasingly important<br />

as the <strong>Sony</strong> Group’s strategic base for<br />

semiconductor production as it establishes a<br />

mass-production system with 65 nanometer<br />

process technology.<br />

200mm wafer in manufacturing process<br />

Surface inspection stage of the LSI production process<br />

31

![PDF [4833KB] - Sony](https://img.yumpu.com/26420643/33/500x640/pdf-4833kb-sony.jpg)