Impact of fuel supply impedance and fuel staging on gas turbine ...

Impact of fuel supply impedance and fuel staging on gas turbine ...

Impact of fuel supply impedance and fuel staging on gas turbine ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1.3 C<strong>on</strong>trol <str<strong>on</strong>g>of</str<strong>on</strong>g> thermo-acoustic instabilities<br />

positive:<br />

∮ t+Tper<br />

t<br />

∫<br />

V cc<br />

p ′ (x, y, z, t ) ˙Q ′ (x, y, z, t )dV d t > 0. (1.3)<br />

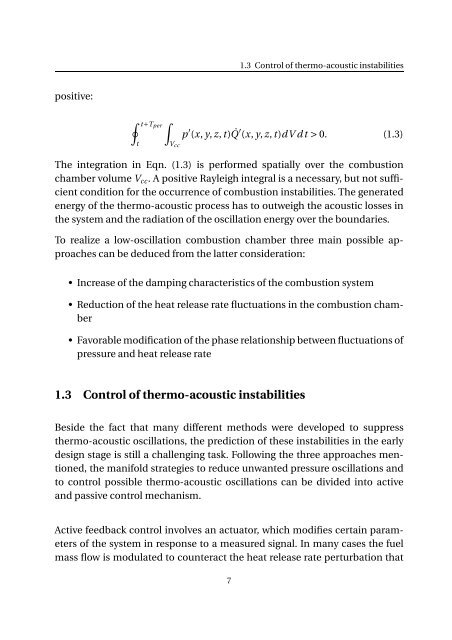

The integrati<strong>on</strong> in Eqn. (1.3) is performed spatially over the combusti<strong>on</strong><br />

chamber volume V cc . A positive Rayleigh integral is a necessary, but not sufficient<br />

c<strong>on</strong>diti<strong>on</strong> for the occurrence <str<strong>on</strong>g>of</str<strong>on</strong>g> combusti<strong>on</strong> instabilities. The generated<br />

energy <str<strong>on</strong>g>of</str<strong>on</strong>g> the thermo-acoustic process has to outweigh the acoustic losses in<br />

the system <str<strong>on</strong>g>and</str<strong>on</strong>g> the radiati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the oscillati<strong>on</strong> energy over the boundaries.<br />

To realize a low-oscillati<strong>on</strong> combusti<strong>on</strong> chamber three main possible approaches<br />

can be deduced from the latter c<strong>on</strong>siderati<strong>on</strong>:<br />

• Increase <str<strong>on</strong>g>of</str<strong>on</strong>g> the damping characteristics <str<strong>on</strong>g>of</str<strong>on</strong>g> the combusti<strong>on</strong> system<br />

• Reducti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the heat release rate fluctuati<strong>on</strong>s in the combusti<strong>on</strong> chamber<br />

• Favorable modificati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the phase relati<strong>on</strong>ship between fluctuati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

pressure <str<strong>on</strong>g>and</str<strong>on</strong>g> heat release rate<br />

1.3 C<strong>on</strong>trol <str<strong>on</strong>g>of</str<strong>on</strong>g> thermo-acoustic instabilities<br />

Beside the fact that many different methods were developed to suppress<br />

thermo-acoustic oscillati<strong>on</strong>s, the predicti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> these instabilities in the early<br />

design stage is still a challenging task. Following the three approaches menti<strong>on</strong>ed,<br />

the manifold strategies to reduce unwanted pressure oscillati<strong>on</strong>s <str<strong>on</strong>g>and</str<strong>on</strong>g><br />

to c<strong>on</strong>trol possible thermo-acoustic oscillati<strong>on</strong>s can be divided into active<br />

<str<strong>on</strong>g>and</str<strong>on</strong>g> passive c<strong>on</strong>trol mechanism.<br />

Active feedback c<strong>on</strong>trol involves an actuator, which modifies certain parameters<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the system in resp<strong>on</strong>se to a measured signal. In many cases the <str<strong>on</strong>g>fuel</str<strong>on</strong>g><br />

mass flow is modulated to counteract the heat release rate perturbati<strong>on</strong> that<br />

7