Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

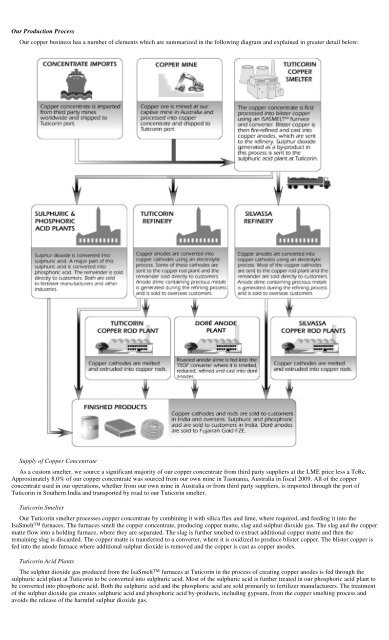

Our Production Process<br />

Our copper business has a number of elements which are summarized in the following diagram and explained in greater detail below:<br />

Supply of Copper Concentrate<br />

As a custom smelter, we source a significant majority of our copper concentrate from third party suppliers at the LME price less a TcRc.<br />

Approximately 8.0% of our copper concentrate was sourced from our own mine in Tasmania, Australia in fiscal 2009. All of the copper<br />

concentrate used in our operations, whether from our own mine in Australia or from third party suppliers, is imported through the port of<br />

Tuticorin in Southern <strong>India</strong> and transported by road to our Tuticorin smelter.<br />

Tuticorin Smelter<br />

Our Tuticorin smelter processes copper concentrate by combining it with silica flux and lime, where required, and feeding it into the<br />

IsaSmelt TM furnaces. The furnaces smelt the copper concentrate, producing copper matte, slag and sulphur dioxide gas. The slag and the copper<br />

matte flow into a holding furnace, where they are separated. The slag is further smelted to extract additional copper matte and then the<br />

remaining slag is discarded. The copper matte is transferred to a converter, where it is oxidized to produce blister copper. The blister copper is<br />

fed into the anode furnace where additional sulphur dioxide is removed and the copper is cast as copper anodes.<br />

Tuticorin Acid Plants<br />

The sulphur dioxide gas produced from the IsaSmelt TM furnaces at Tuticorin in the process of creating copper anodes is fed through the<br />

sulphuric acid plant at Tuticorin to be converted into sulphuric acid. Most of the sulphuric acid is further treated in our phosphoric acid plant to<br />

be converted into phosphoric acid. Both the sulphuric acid and the phosphoric acid are sold primarily to fertilizer manufacturers. The treatment<br />

of the sulphur dioxide gas creates sulphuric acid and phosphoric acid by-products, including gypsum, from the copper smelting process and<br />

avoids the release of the harmful sulphur dioxide gas.