Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fabrication Facility<br />

The fabrication facility at Korba has two parts, a cast house and a sheet rolling shop.<br />

Cast House<br />

The cast house uses continuous rod casters from Continuus-Properzi S.p.A. and has a foundry which has twin-roll continuous casters with a<br />

SNIF degasser and hydraulically driven semi-continuous ingot casting machine to produce ingots and wire rods.<br />

Sheet Rolling Shop<br />

The sheet rolling shop has three parts: a hot rolling mill with a capacity of 75,000 tpa, an older cold rolling mill with a capacity of 30,000<br />

tpa and a newer cold rolling mill commissioned in 2004 with a capacity of 36,000 tpa. Molten metal is cast into slabs and then either hot-rolled<br />

and sold as hot-rolled sheets or converted into cold-rolled sheets in the cold rolling mills. Alternatively, molten metal is directly used in strip<br />

casting and then fed to the cold rolling mills to convert it into cold-rolled sheets or coils.<br />

Captive Power Plants<br />

Smelting requires a substantial continuous supply of power and interruptions can cause molten metal to solidify and damage or destroy the<br />

pots. Power for the Korba facility is for the most part provided by the older coal-based 270 MW captive power plant commissioned in 1988<br />

together with a newer coal-based 540 MW captive power plant commissioned in March 2006. Thermal coal is a key raw material required for<br />

the operation of BALCO’s captive power plants. In April 2008, BALCO entered into two five-year coal supply agreements with SECL for the<br />

supply of thermal coal by SECL to BALCO, which represents approximately 66% of its thermal coal requirements, with the remainder<br />

obtained through open market purchases and imports of coal.<br />

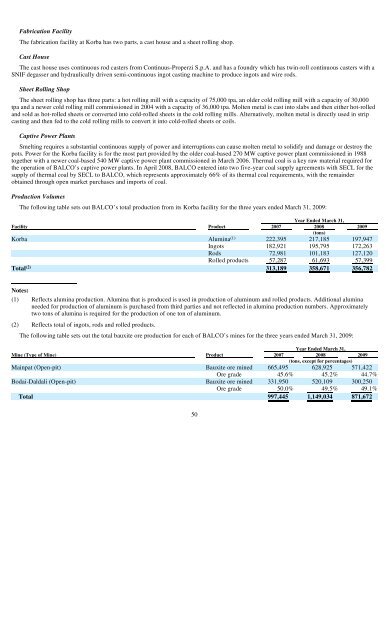

Production Volumes<br />

The following table sets out BALCO’s total production from its Korba facility for the three years ended March 31, 2009:<br />

Year Ended March 31,<br />

Facility Product 2007 2008 2009<br />

(tons)<br />

Korba Alumina (1) 222,395 217,185 197,947<br />

Ingots 182,921 195,795 172,263<br />

Rods 72,981 101,183 127,120<br />

Rolled products 57,287 61,693 57,399<br />

Total (2) 313,189 358,671 356,782<br />

Notes:<br />

(1) Reflects alumina production. Alumina that is produced is used in production of aluminum and rolled products. Additional alumina<br />

needed for production of aluminum is purchased from third parties and not reflected in alumina production numbers. Approximately<br />

two tons of alumina is required for the production of one ton of aluminum.<br />

(2) Reflects total of ingots, rods and rolled products.<br />

The following table sets out the total bauxite ore production for each of BALCO’s mines for the three years ended March 31, 2009:<br />

Year Ended March 31,<br />

Mine (Type of Mine) Product 2007 2008 2009<br />

(tons, except for percentages)<br />

Mainpat (Open-pit) Bauxite ore mined 665,495 628,925 571,422<br />

Ore grade 45.6% 45.2% 44.7%<br />

Bodai-Daldali (Open-pit) Bauxite ore mined 331,950 520,109 300,250<br />

Ore grade 50.0% 49.5% 49.1%<br />

Total 997,445 1,149,034 871,672<br />

50