Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The reserves as of March 31, 2009 at BALCO’s mines at Mainpat and Bodai-Daldali have been determined by verifying that the integrated<br />

operation is economic at an aluminum price of $2,502 per ton, which is the average metal price for the three fiscal years ending March 31,<br />

2009.<br />

A drill hole spacing of 50 meters by 50 meters is used to determine the proven reserves while a drill hole spacing of 100 meters by 100<br />

meters is used to determine the probable reserves.<br />

The mining dilution and mining recovery factors applied to determine the reserves at the Mainpat mine are 6.4% and 62.0%, respectively,<br />

while the factors applied at the Bodai-Daldali mine are 5.0% and 65.0%, respectively. The parameters for Mainpat are derived from the<br />

reconciliation of actual production against the geological model, while the parameters for Bodai-Daldali are based on estimates.<br />

For fiscal 2009, the smelting and refining recovery from the mines for the production of alumina was at 76.9%. In fiscal 2009, all mining<br />

and transportation of the bauxite was done by contractors and the total cost for this was Rs. 972 ($19.1) per ton of bauxite.<br />

For fiscal 2009, the stripping ratio at the Mainpat mine was 1.0:2.3 with 2.3 tons of waste overburden being removed to mine one ton of ore,<br />

while the stripping ratio at the Bodai-Daldali mine was 1.0:2.9 with 2.9 tons of waste overburden being removed to mine one ton of ore. The<br />

strip ratio for the remaining reserves at Mainpat is 4.8 tons of waste per ton of ore while at Bodai-Daldali it is 5.0 tons of waste per ton of ore.<br />

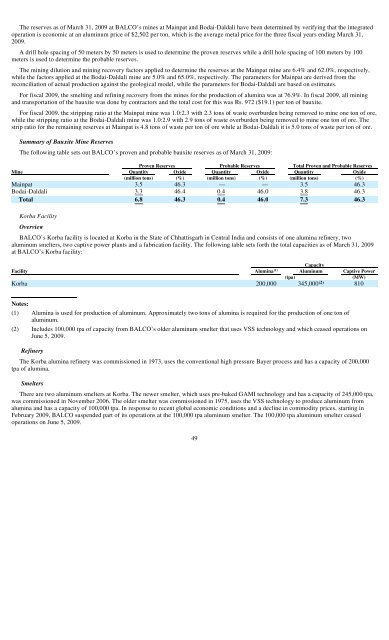

Summary of Bauxite Mine Reserves<br />

The following table sets out BALCO’s proven and probable bauxite reserves as of March 31, 2009:<br />

Proven Reserves Probable Reserves Total Proven and Probable Reserves<br />

Mine Quantity Oxide Quantity Oxide Quantity Oxide<br />

(million tons) (%) (million tons) (%) (million tons) (%)<br />

Mainpat 3.5 46.3 — — 3.5 46.3<br />

Bodai-Daldali 3.3 46.4 0.4 46.0 3.8 46.3<br />

Total 6.8 46.3 0.4 46.0 7.3 46.3<br />

Korba Facility<br />

Overview<br />

BALCO’s Korba facility is located at Korba in the State of Chhattisgarh in Central <strong>India</strong> and consists of one alumina refinery, two<br />

aluminum smelters, two captive power plants and a fabrication facility. The following table sets forth the total capacities as of March 31, 2009<br />

at BALCO’s Korba facility:<br />

Capacity<br />

Facility Alumina (1) Aluminum Captive Power<br />

(tpa) (MW)<br />

Korba 200,000 345,000 (2) 810<br />

Notes:<br />

(1) Alumina is used for production of aluminum. Approximately two tons of alumina is required for the production of one ton of<br />

aluminum.<br />

(2) Includes 100,000 tpa of capacity from BALCO’s older aluminum smelter that uses VSS technology and which ceased operations on<br />

June 5, 2009.<br />

Refinery<br />

The Korba alumina refinery was commissioned in 1973, uses the conventional high pressure Bayer process and has a capacity of 200,000<br />

tpa of alumina.<br />

Smelters<br />

There are two aluminum smelters at Korba. The newer smelter, which uses pre-baked GAMI technology and has a capacity of 245,000 tpa,<br />

was commissioned in November 2006. The older smelter was commissioned in 1975, uses the VSS technology to produce aluminum from<br />

alumina and has a capacity of 100,000 tpa. In response to recent global economic conditions and a decline in commodity prices, starting in<br />

February 2009, BALCO suspended part of its operations at the 100,000 tpa aluminum smelter. The 100,000 tpa aluminum smelter ceased<br />

operations on June 5, 2009.<br />

49