Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

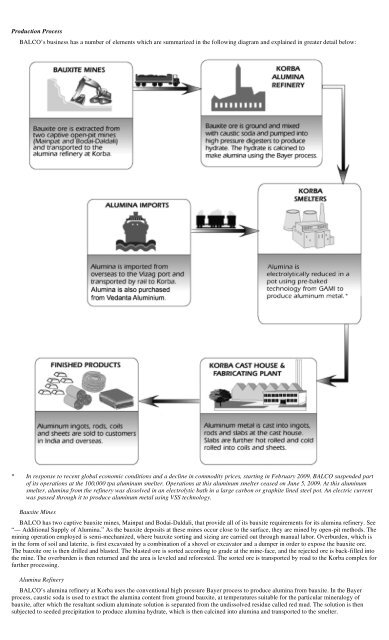

Production Process<br />

BALCO’s business has a number of elements which are summarized in the following diagram and explained in greater detail below:<br />

* In response to recent global economic conditions and a decline in commodity prices, starting in February 2009, BALCO suspended part<br />

of its operations at the 100,000 tpa aluminum smelter. Operations at this aluminum smelter ceased on June 5, 2009. At this aluminum<br />

smelter, alumina from the refinery was dissolved in an electrolytic bath in a large carbon or graphite lined steel pot. An electric current<br />

was passed through it to produce aluminum metal using VSS technology.<br />

Bauxite Mines<br />

BALCO has two captive bauxite mines, Mainpat and Bodai-Daldali, that provide all of its bauxite requirements for its alumina refinery. See<br />

“— Additional Supply of Alumina.” As the bauxite deposits at these mines occur close to the surface, they are mined by open-pit methods. The<br />

mining operation employed is semi-mechanized, where bauxite sorting and sizing are carried out through manual labor. Overburden, which is<br />

in the form of soil and laterite, is first excavated by a combination of a shovel or excavator and a dumper in order to expose the bauxite ore.<br />

The bauxite ore is then drilled and blasted. The blasted ore is sorted according to grade at the mine-face, and the rejected ore is back-filled into<br />

the mine. The overburden is then returned and the area is leveled and reforested. The sorted ore is transported by road to the Korba complex for<br />

further processing.<br />

Alumina Refinery<br />

BALCO’s alumina refinery at Korba uses the conventional high pressure Bayer process to produce alumina from bauxite. In the Bayer<br />

process, caustic soda is used to extract the alumina content from ground bauxite, at temperatures suitable for the particular mineralogy of<br />

bauxite, after which the resultant sodium aluminate solution is separated from the undissolved residue called red mud. The solution is then<br />

subjected to seeded precipitation to produce alumina hydrate, which is then calcined into alumina and transported to the smelter.