Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

have a drill-hole spacing of 30 meters and have been classified as probable reserves as there is less certainty of the modifying factors since the<br />

detailed mine design has not yet been completed.<br />

CMT does not use a copper equivalent calculation for the determination of stope limits as the relationship between the copper and gold<br />

grades is essentially linear, allowing the gold credits to be deducted from operating costs.<br />

The proportion of sub-economic dilution in the reserves varies with the amount of internal dilution and the amount of over-draw. Due to the<br />

caving process mixing ore from previous levels, remnant material and material from mineralized halo, it is difficult to determine the level of<br />

external dilution, leading CMT to derive the modifying factors from the reconciliation of historical production against the grade and tonnage of<br />

the primary ore mined.<br />

For fiscal 2009, the metallurgical recovery was 90.2% for copper, 65.5% for gold and 62.9% for silver. For fiscal 2009, the contract mining<br />

and milling cost was AUD 2,963 ($2,057.64 or Rs. 104,672) per ton, administration and environment cost was AUD 413 ($286.81 or<br />

Rs. 14,590) per ton and transportation cost was AUD 448 ($311.11 or Rs. 15,826) per ton. Correspondingly the TcRc was AUD 398 ($276.39<br />

or Rs. 14,060) per ton.<br />

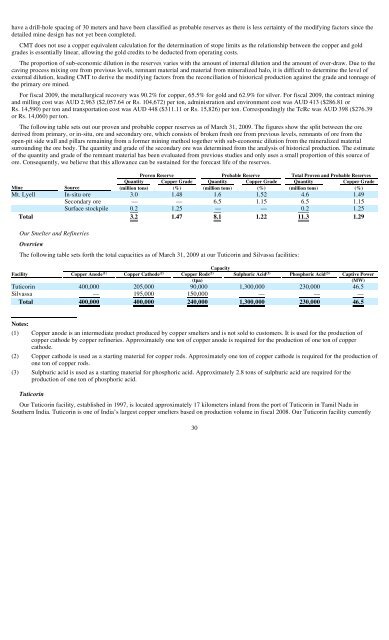

The following table sets out our proven and probable copper reserves as of March 31, 2009. The figures show the split between the ore<br />

derived from primary, or in-situ, ore and secondary ore, which consists of broken fresh ore from previous levels, remnants of ore from the<br />

open-pit side wall and pillars remaining from a former mining method together with sub-economic dilution from the mineralized material<br />

surrounding the ore body. The quantity and grade of the secondary ore was determined from the analysis of historical production. The estimate<br />

of the quantity and grade of the remnant material has been evaluated from previous studies and only uses a small proportion of this source of<br />

ore. Consequently, we believe that this allowance can be sustained for the forecast life of the reserves.<br />

Proven Reserve Probable Reserve Total Proven and Probable Reserves<br />

Quantity Copper Grade Quantity Copper Grade Quantity Copper Grade<br />

Mine Source (million tons) (%) (million tons) (%) (million tons) (%)<br />

Mt. Lyell In-situ ore 3.0 1.48 1.6 1.52 4.6 1.49<br />

Secondary ore — — 6.5 1.15 6.5 1.15<br />

Surface stockpile 0.2 1.25 — — 0.2 1.25<br />

Total 3.2 1.47 8.1 1.22 11.3 1.29<br />

Our Smelter and Refineries<br />

Overview<br />

The following table sets forth the total capacities as of March 31, 2009 at our Tuticorin and Silvassa facilities:<br />

Capacity<br />

Facility Copper Anode (1) Copper Cathode (2) Copper Rods (2) Sulphuric Acid (3) Phosphoric Acid (3) Captive Power<br />

(tpa) (MW)<br />

Tuticorin 400,000 205,000 90,000 1,300,000 230,000 46.5<br />

Silvassa — 195,000 150,000 — —<br />

Total 400,000 400,000 240,000 1,300,000 230,000<br />

—<br />

46.5<br />

Notes:<br />

(1) Copper anode is an intermediate product produced by copper smelters and is not sold to customers. It is used for the production of<br />

copper cathode by copper refineries. Approximately one ton of copper anode is required for the production of one ton of copper<br />

cathode.<br />

(2) Copper cathode is used as a starting material for copper rods. Approximately one ton of copper cathode is required for the production of<br />

one ton of copper rods.<br />

(3) Sulphuric acid is used as a starting material for phosphoric acid. Approximately 2.8 tons of sulphuric acid are required for the<br />

production of one ton of phosphoric acid.<br />

Tuticorin<br />

Our Tuticorin facility, established in 1997, is located approximately 17 kilometers inland from the port of Tuticorin in Tamil Nadu in<br />

Southern <strong>India</strong>. Tuticorin is one of <strong>India</strong>’s largest copper smelters based on production volume in fiscal 2008. Our Tuticorin facility currently<br />

30