Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

Sterlite Industries (India) Limited - Sterlite Industries India Ltd.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

consists of a 400,000 tpa copper smelter, a 205,000 tpa copper refinery, a 90,000 tpa copper rod plant, a 1,300,000 tpa sulphuric acid plant, a<br />

230,000 tpa phosphoric acid plant, a 700 tpa doré anode plant and two captive power plants with capacities of 22.5MW and 24.0MW,<br />

respectively.<br />

The captive power plants with a total capacity of 46.5MW, together with a further 11.2 MW generated from the smelter waste heat boiler,<br />

meet most of the facility’s power requirements. The remaining power requirements of the facility, which amount to approximately 22.5% of its<br />

total power requirements in fiscal 2009, are obtained from the state power grid. Our captive power plants at Tuticorin operate on low sulphur<br />

heavy stock procured through long-term contracts with various oil companies.<br />

The smelter at the Tuticorin facility utilizes IsaSmelt TM furnace technology. The refinery uses IsaProcess TM technology to produce copper<br />

cathode and the copper rod plant uses Properzi Continuously Cast and Rolled, or CCR, copper rod technology from Continuus-Properzi S.p.A.,<br />

Italy, to produce copper rods.<br />

Silvassa<br />

Our Silvassa facility, established in 1997, is located approximately 140 kilometers from Mumbai in the union territory of Dadra and Nagar<br />

Haveli in Western <strong>India</strong>. Our Silvassa facility currently consists of a 195,000 tpa copper refinery and two copper rod plants with a total<br />

installed capacity of 150,000 tpa of copper rods. Its refinery uses IsaProcess TM technology in the production of copper cathode and its copper<br />

rod plants use Properzi CCR copper rod technology. Our Silvassa facility draws on the state power grid to satisfy its power requirements.<br />

Fujairah<br />

Fujairah Gold FZE is located in the Fujairah Free Zone-2. Our Fujairah facility is strategically located 130 kilometers east of Dubai and is<br />

on the coast of the Arabian Sea. Fujairah Gold FZE recently completed its precious metal refinery project at a cost of $5.2 million. The<br />

precious metal refinery was commissioned in March 2009 and began production in April 2009, with a capacity of 20 tons of gold and 85 tons<br />

of silver. Outotec oyj, Finland, the pioneer in providing technology for extraction and refining of precious metals, supplied the technology for<br />

the precious metal refinery. Fujairah Gold FZE is also executing a copper rods project at its Fujairah facility, which is expected to be completed<br />

by the end of 2009 with a capacity of 100,000 tpa. Continuus Properzi S.p.A., Italy, is supplying the rod mill equipment for this project, and the<br />

copper cathode required for the copper rod plant is expected to be sourced from the smelters of the Vedanta group.<br />

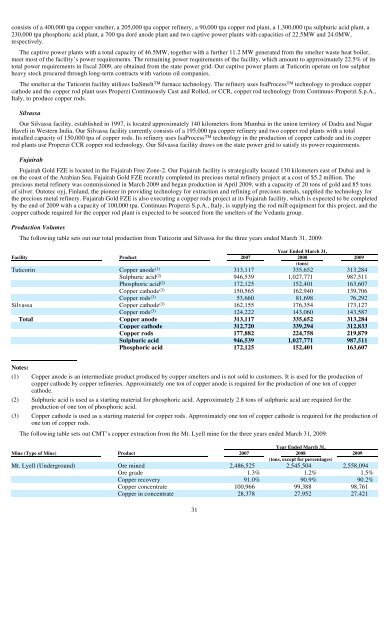

Production Volumes<br />

The following table sets out our total production from Tuticorin and Silvassa for the three years ended March 31, 2009:<br />

Year Ended March 31,<br />

Facility Product 2007 2008 2009<br />

(tons)<br />

Tuticorin Copper anode (1) 313,117 335,652 313,284<br />

Sulphuric acid (2) 946,539 1,027,771 987,511<br />

Phosphoric acid (2) 172,125 152,401 163,607<br />

Copper cathode (3) 150,565 162,940 139,706<br />

Copper rods (3) 53,660 81,698 76,292<br />

Silvassa Copper cathode (3) 162,155 176,354 173,127<br />

Copper rods (3) 124,222 143,060 143,587<br />

Total Copper anode 313,117 335,652 313,284<br />

Copper cathode 312,720 339,294 312,833<br />

Copper rods 177,882 224,758 219,879<br />

Sulphuric acid 946,539 1,027,771 987,511<br />

Phosphoric acid 172,125 152,401 163,607<br />

Notes:<br />

(1) Copper anode is an intermediate product produced by copper smelters and is not sold to customers. It is used for the production of<br />

copper cathode by copper refineries. Approximately one ton of copper anode is required for the production of one ton of copper<br />

cathode.<br />

(2) Sulphuric acid is used as a starting material for phosphoric acid. Approximately 2.8 tons of sulphuric acid are required for the<br />

production of one ton of phosphoric acid.<br />

(3) Copper cathode is used as a starting material for copper rods. Approximately one ton of copper cathode is required for the production of<br />

one ton of copper rods.<br />

The following table sets out CMT’s copper extraction from the Mt. Lyell mine for the three years ended March 31, 2009:<br />

Year Ended March 31,<br />

Mine (Type of Mine) Product 2007 2008 2009<br />

(tons, except for percentages)<br />

Mt. Lyell (Underground) Ore mined 2,486,525 2,545,504 2,558,094<br />

Ore grade 1.3% 1.2% 1.5%<br />

Copper recovery 91.0% 90.9% 90.2%<br />

Copper concentrate 100,966 99,388 98,761<br />

Copper in concentrate 28,378 27,952 27,421<br />

31